Your

Pick & Place

Partner

Our intelligent pick and place robot systems handle a large variety of items, from heavy parcels to small items, in boxes or bags. We partner with leading integrators and customers to ensure the most efficient use of robotics in warehouses.

Read more

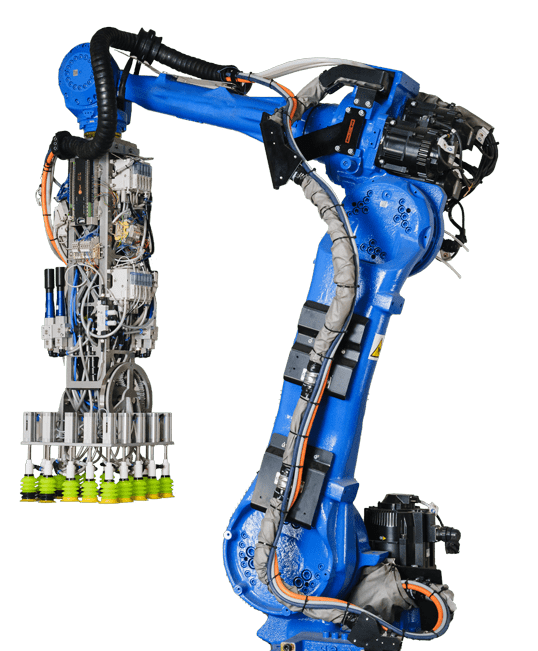

Smart

Mixed Case Palletizer

Boost efficiency and reach same-day delivery with the Smart Mixed Case Palletizer, our next generation palletizing solution for the reliable and efficient palletizing of mixed cases. It allows you to improve your pre-sortation process, resulting in greater flexibility and increased warehouse capacity.

Pick me >

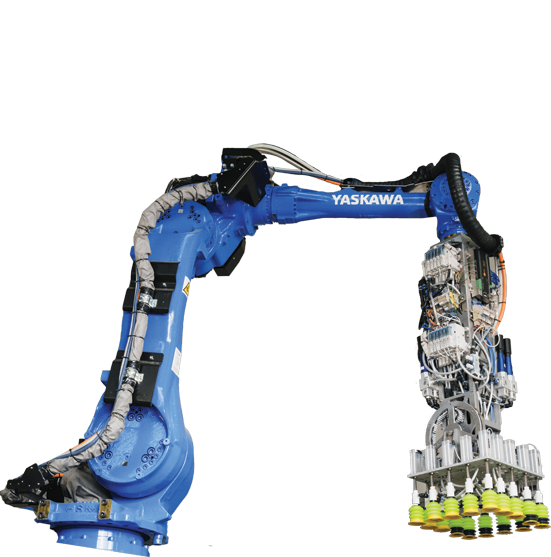

Smart

Item Picker

Tackle increasing consumer demand and rising labor shortages in your fulfillment process with the Smart Item Picker: a reliable single item picking solution for the efficient picking and placing of a wide variety of items. From order picking to sorting, the Smart Item Picker will help you improve operational accuracy and efficiency and enables you to reach uninterrupted operation.

Pick me >

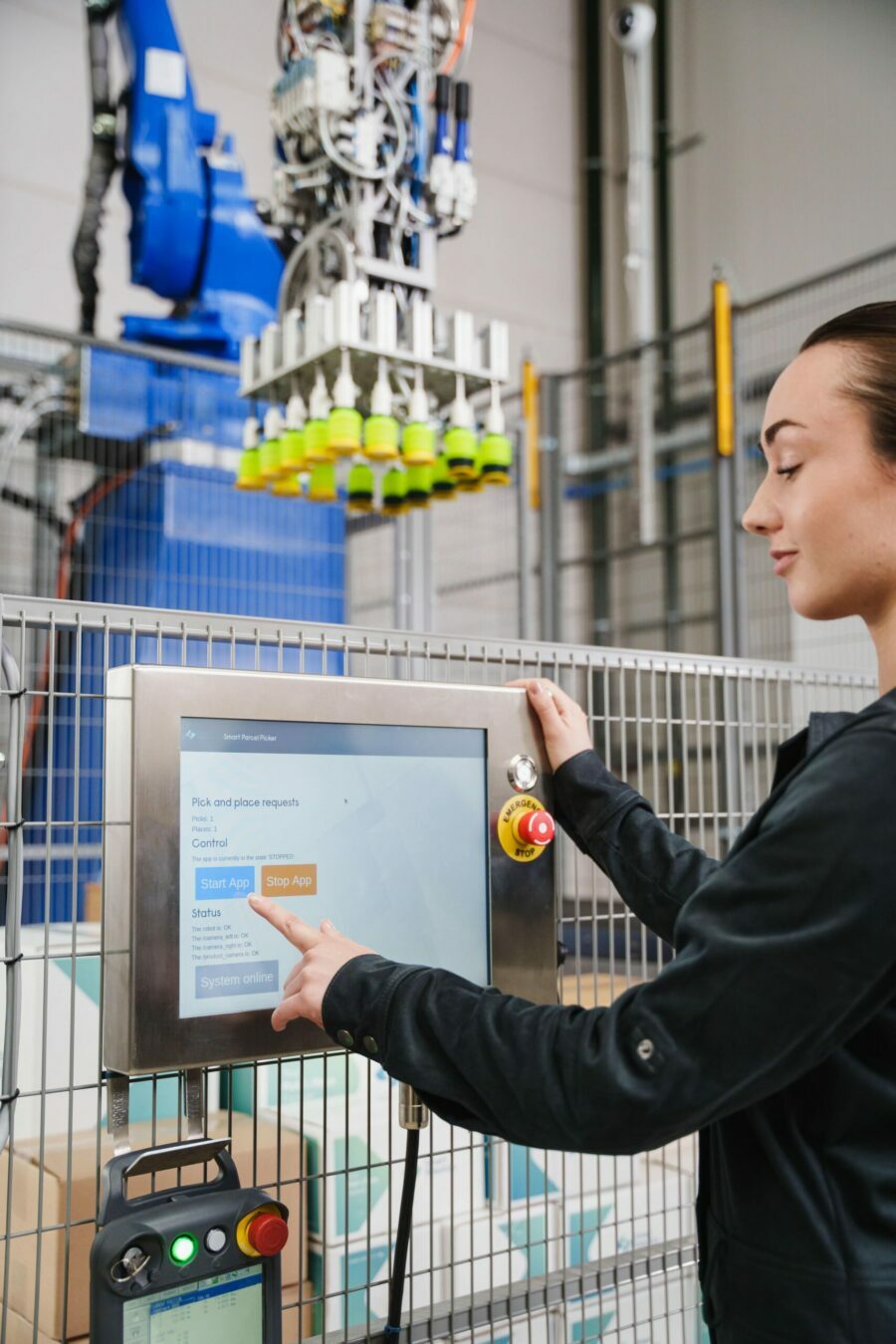

Smart

Parcel Picker

Reach optimal parcel throughput with the Smart Parcel Picker: an intelligent parcel picking robot for the reliable depalletizing and unloading of an extensive range of parcels, ranging from cardboard boxes to plastic bags. Tailored to your parcel logistics process, it will help you improve operational efficiency and maximize capacity.

Pick me >

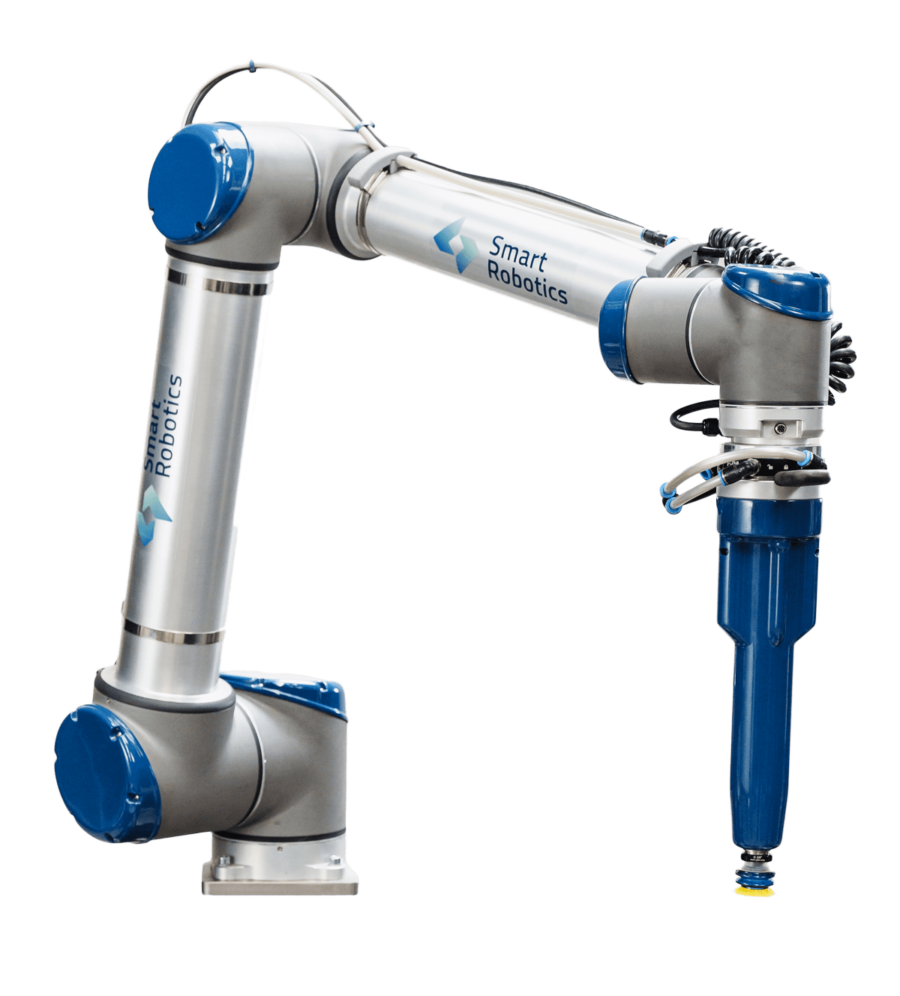

Smart

Palletizer

Get ready to improve your production process with the Smart Palletizer, an intelligent, flexible and compact pick & place system for the reliable palletizing of your products. Tailored to your production setup and easy to use by any operator, it will improve operational efficiency, help you save time and costs and scale your business.

Pick me >

Our Promise

When acquiring our pick & place systems, we promise to provide reliable technology and high-level services for your fulfillment centre or warehouse production process. What stands out in our solutions is that we’re a picking automation service provider too and you won’t require a robotics engineer to work on any of our pick & place systems after installation. For additional support, you can subscribe to our hardware maintenance subscription which covers updates and spare parts when required.

HIGH LEVEL OF

Performance &

Reliability

- Fast, accurate & easy to use

- Handles a large variety of items

- Delivers optimal results in complex environments

- Remote monitoring and reporting

HIGH LEVEL OF

Learning &

Adaptability

- Artificial intelligence that learns and adapts continuously to improve efficiency and productivity

- When one pick & place system learns, they all improve

- Hardware agnostic

HIGH LEVEL OF

Flexibility &

Scalability

- Easy to deploy

- Seamless integrations

- Compatible with most warehouse systems

HIGH LEVEL OF

Service &

ROI

- Dedicated customer success team

- 24/7 support

- Performance guaranteed

- Return on investment – within a year

Near- human performance

As your pick & place partner, we build a tailored solution with reliable hardware, intelligent software and a good service package that ensures you meet your operational KPIs and have the flexibility to scale up and receive the best ROI and payback.

Our unique software platform enables us to take full control over all vision and motion elements of our robots as well as the task planning algorithms to reach a human-performance level. We also work with many hardware suppliers, which enables our software to run on different types of robotic hardware best suited for your warehouse or fulfilment process. Are you ready to future-proof your warehouse/fulfilment processes?

Book an

Online Demo

Learn how to improve fulfillment efficiency with a reliable pick and place robot

Pick & Place customers

Palletizing in the pharma industry at Bayer

07-12-2022

World-renowned Bayer, a pharmaceuticals and life sciences company, has welcomed the Smart Palletizer as a new colleague. Read more about why they recommend Smart Robotics to their partners.

Discover case studyItem picking pilot at Bol.com

07-12-2022

Did you know that Bol.com, one of the largest Dutch online retail & distribution companies, executed a pilot with Smart Robotics regarding the implementation of a Smart Item Picker?

Discover case studyPalletizing chocolates at Heinerle-Berggold

07-12-2022

Heinerle-Berggold Shokoladen GmbH, a German company specializing in specialty quality chocolates, has implemented a Smart Palletizer to help tackle labor shortages and to ensure on-time delivery to their customers.

Discover case study