Table of contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

2023 apparel fulfillment trends that emphasize the need for automation

Table of contents

The apparel industry has been relatively hesitant to implement automation in their fulfillment processes. However, in 2023, there is an increasing need to have a more efficient and sustainable fashion fulfillment process. Add to that the growing pressure on the existing workforce as well as the global labor shortage that impacts the apparel industry, and there is your need for warehouse fulfillment automation. Let us take a look at the 2023 fulfillment and logistics trends for the apparel industry that emphasize the need for automation.

2023 apparel fulfillment trends

Improve warehouse fulfillment efficiency and throughput

Online consumer demand continues to increase globally, as more and more people do their shopping online. As we all know, the pandemic has definitely accelerated this growth. However, this growth means that apparel fulfillment and logistics processes are facing rising pressure to keep up with consumer demand and meet the high-volume throughput needed. Hence, fashion manufacturers are looking into how they can improve warehouse fulfillment efficiency to increase throughput, save time and reduce costs.

Tackle supply chain disruptions and labor shortages

Another lesson learnt from the pandemic is that the supply chain is easily disrupted on a global scale. On that note, many apparel manufacturers are exploring how to improve their supply chain and rely less on supplies and manufacturing far from their sales area. There is a trend towards producing apparel closer to home to create a more local supply chain with decentralized warehouses. However, especially in Europe and the US, labor shortages are existent and labor that is available is rather costly. On that account, automating warehouse fulfillment and logistics processes are a great way to be able to meet consumer demands for local produce and tackle labor shortages and rising costs at the same time.

Sustainable and local production with automation

Besides improving efficiency and tackling supply chain disruptions, sustainability is another reason for apparel companies to implement automation in their production and fulfillment processes. As consumers are increasingly aware of the impact of fashion on the environment, they are looking for apparel that has a more sustainable character. To answer this call, apparel manufacturers are trying to move production closer to the sales markets, as this saves time, money and has a positive impact on the environment due to a reduced carbon footprint.

Alleviate pressure on existing workforce

As online consumer demand is rising and labor shortages are growing, the existing workforce in fashion fulfillment and logistics is facing higher pressure and more labor-intensive work. Automation, especially of repetitive and physically challenging tasks, can alleviate the pressure on these workers and allow them to spend their time on tasks that require human intelligence and creativity.

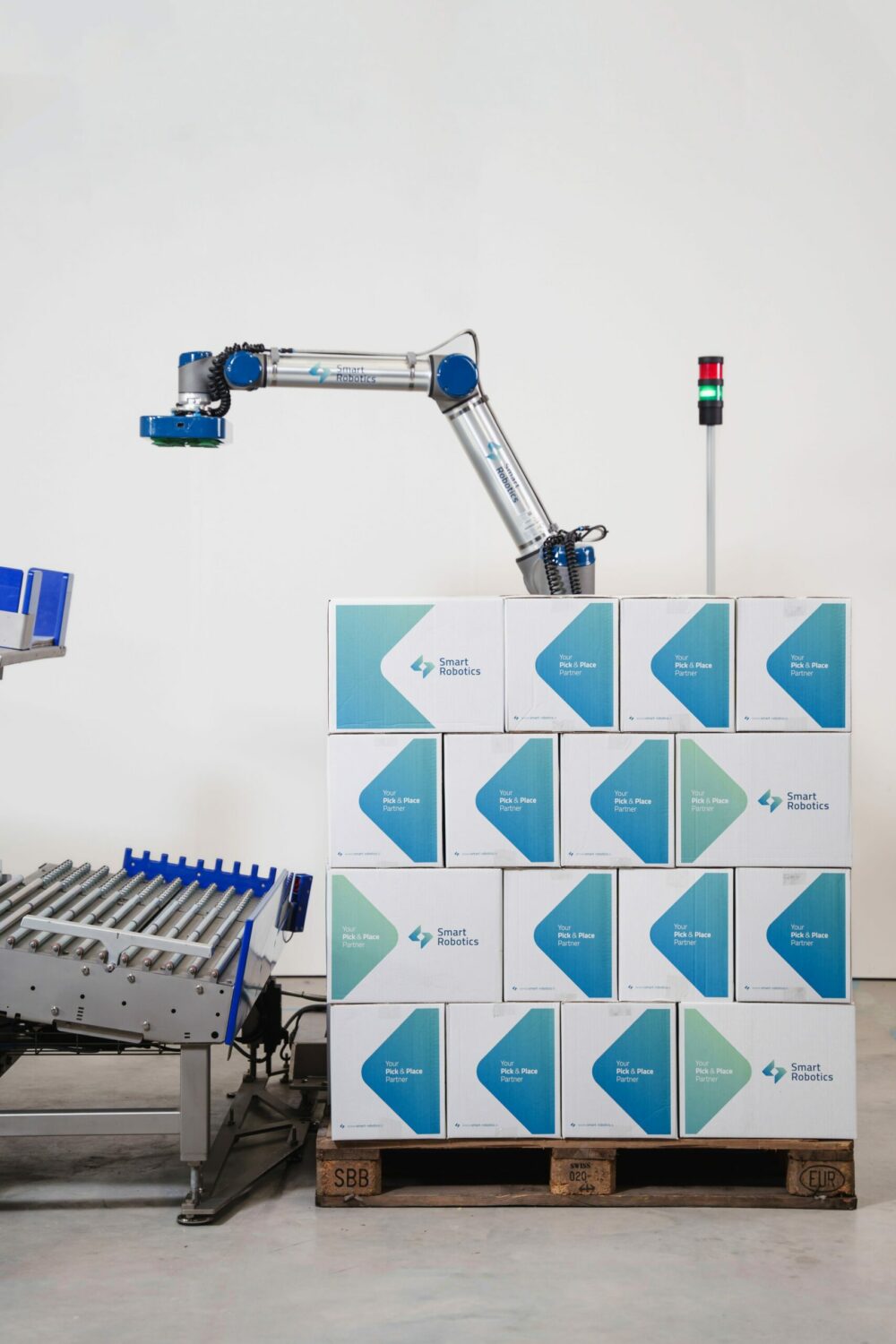

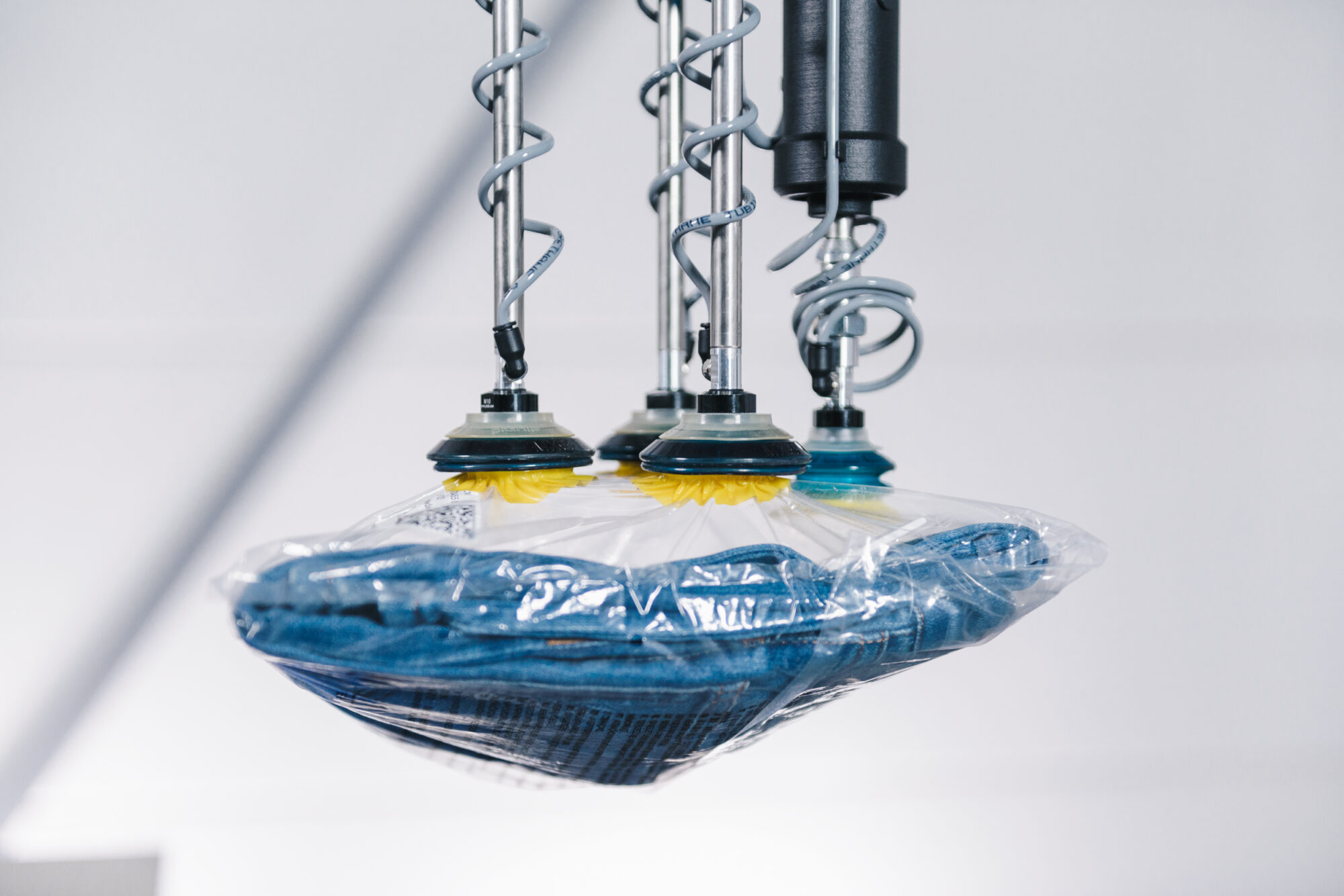

Robotic pick & place automation to improve warehouse fulfillment efficiency

As online order volumes increase, labor shortages grow and the demand for more sustainable, local apparel production rises, the need for automation is growing. Considering there are many repetitive pick and place tasks within apparel fulfillment, robotic pick and place automation can be a great way to support the existing workforce, optimize productivity and improve throughput. By assisting in tasks such as order fulfillment, sorting, palletizing and parcel handling, pick and place automation can help apparel companies meet customer demand and expectations and achieve a more frictionless supply chain.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.