Smart Palletizer Flexible palletizing

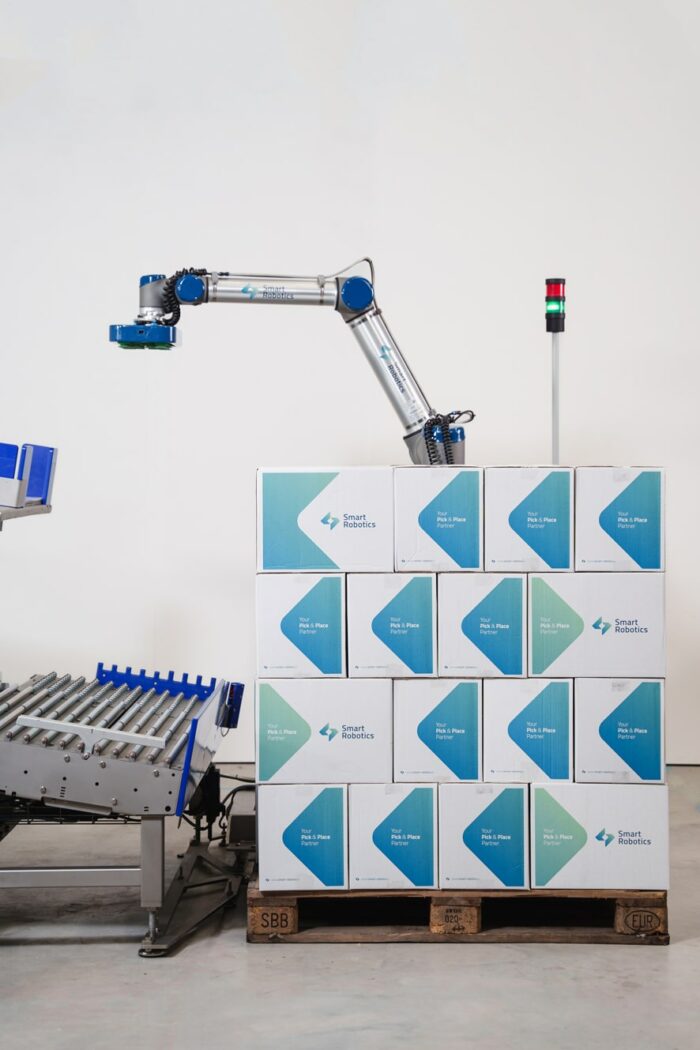

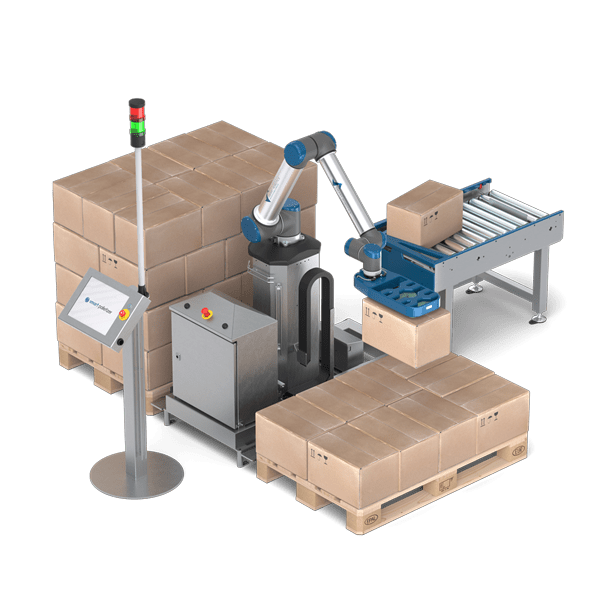

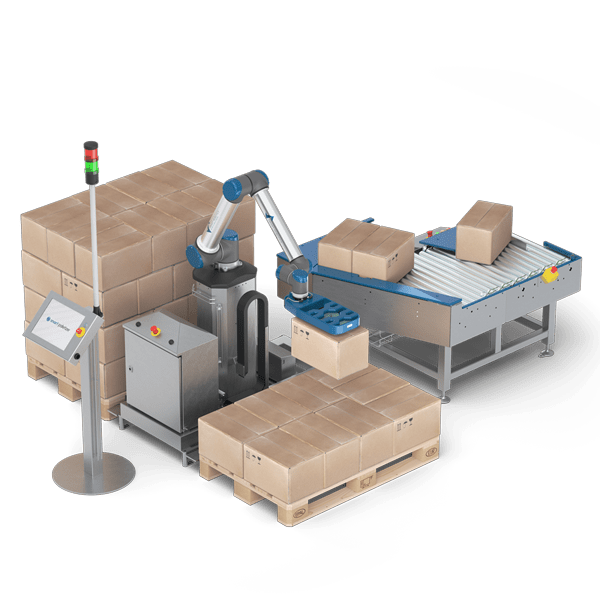

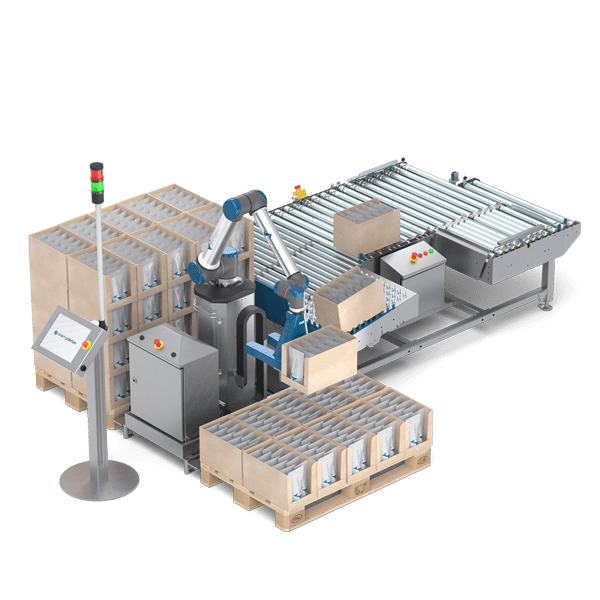

Improve operational efficiency with the Smart Palletizer, a reliable, adaptable and compact pick & place system for the palletizing of a large variety of products.

Book an online demoSmart Palletizer advantages

High level of performance & reliability

Handles a large variety of products & stacking patterns and is easy to use by any operator. It allows for safe cooperation with people. In addition, our remote monitoring & reporting ensures reliable performance.

High level of learning & adaptability

With the Smart Product Editor customers can easily add and adjust products and stacking patterns. In addition, our AI software learns and adapts continuously to improve efficiency and productivity.

High level of flexibility & scalability

The Smart Palletizer can be tailored to your needs and production setup. We ensure quick and easy installation within one day.

High level of service & ROI

We offer picking automation as a service: hardware, software and service included. Our Online Helpdesk and dedicated customer service team ensure reliable and uninterrupted operation resulting in an ROI of 1 to 2 years.

Optimize end-of-line performance

Watch video

Efficient and

reliable palletizing

With the Smart Palletizer, we help customers in markets such as Pharma and Food – including coffee, snacks, bakery and many others – to overcome various challenges in their production or fulfillment process:

- Growing Labor shortages

- Increasing consumer demand and variety

- Need for efficiency whilst decreasing operation costs

- Dissatisfied employees and high turnover rate due to boring, repetitive and physically straining work

The Smart Palletizer is a reliable palletizer system able to handle a large variety of products and stacking patterns . It can easily be tailored to comply to changing market demands and customer needs. The Smart Palletizer allows you to improve operational accuracy and efficiency without major changes to your existing process. Our Technology Trinity ensures reliable and uninterrupted operation, allowing you to save time and costs and scale your business.

Tailored palletizing solution

You want to improve operational efficiency in a quick and easy way with a palletizer and want the quality that Smart Robotics can provide.

You are looking for a palletizer system that outperforms its competitors and can handle many product variations as well as complicated stacking patterns.

Ready to pick up the pace with our reliable pick & place solutions?

Contact us

Smart Palletizer customers

Discover how our customers have improved their production and fulfillment processes with a reliable and efficient pick and place solution.

Heinerle-Berggold Shokoladen GmbH, a German company specializing in specialty quality chocolates, has implemented a Smart Palletizer to help tackle labor shortages and to ensure on-time delivery to their customers.

Read more >3

shift operation

99.7%

availability

“The Smart Palletizer has helped us solve our end-of-line challenges. It runs a 3-shift operation and reaches an availability of almost 100%.”

Na-Nomi, a Dutch co-packing company, are very happy with their Smart Palletizer. It is a very user-friendly system for palletizing.

Read more >16

Hours a day

5

Days per week

99%

Availability

“The user-friendliness of the system played a large role in the decision making process.”

World-renowned Bayer, a pharmaceuticals and life sciences company, has welcomed the Smart Palletizer as a new colleague. Read more about why they recommend Smart Robotics to their partners.

Read more >Safe

palletizing system

Short

delivery times

“It is no surprise I would recommend Smart Robotics to our partners”

“The Smart Palletizer has helped us solve our end-of-line challenges. It runs a 3-shift operation and reaches an availability of almost 100%.”

3

shift operation

24/7 reliability and efficiency

99.7%

availability

Reliable palletizing of chocolates

“The user-friendliness of the system played a large role in the decision making process.”

16

Hours a day

Palletizing a wide variety of products

5

Days per week

Safe cooperation with human employees

99%

Availability

Reliable and uninterrupted operation

“It is no surprise I would recommend Smart Robotics to our partners”

Safe

palletizing system

One of the most popular colleagues

Short

delivery times

No need to interrupt production

Learn how to improve end-of-line efficiency with the Smart PalletizerBook an online demo

FAQ

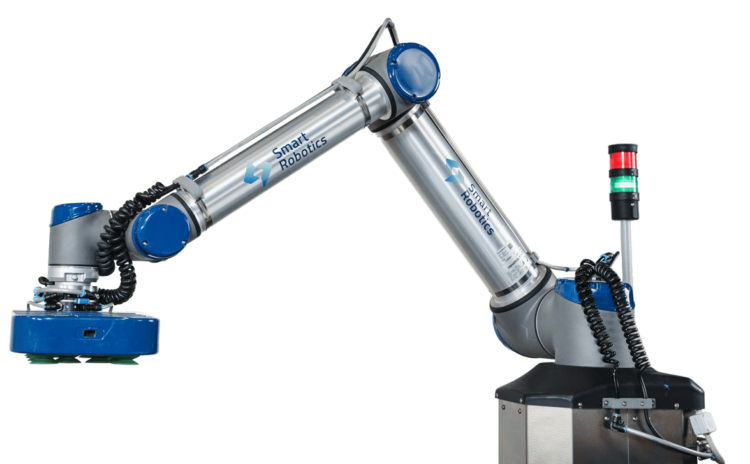

Palletizing cobot

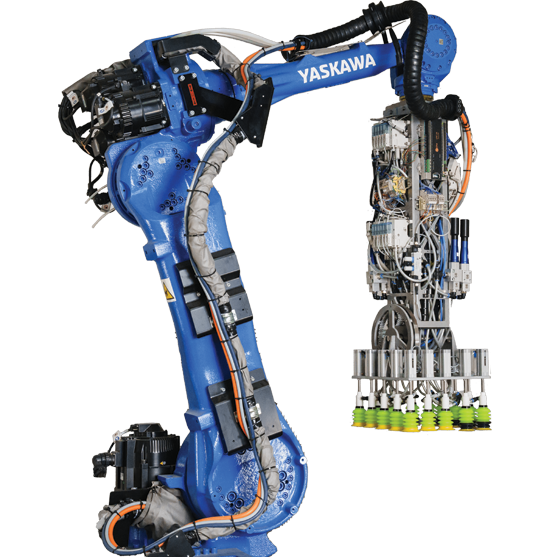

A cobot palletizer or robot palletizer is an automated material handling system that stacks goods and products onto a pallet. It is usually placed at the end of a production line and allows for stability, precision and high efficiency.

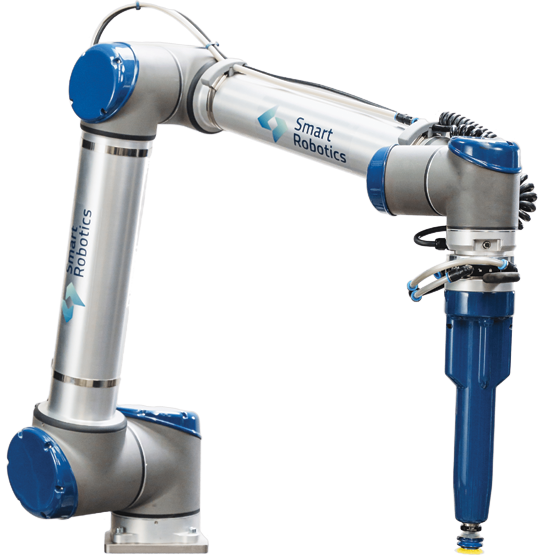

Read more about cobot palletizers >A palletizer is an end-of-line system that often consists of a robot or cobot arm with a gripper attached for the picking and placing of products in a defined stacking pattern onto a pallet. Within Smart Robotics, we have developed the Smart Palletizer for this task; an intelligent, flexible and compact end-of-line cobot used for the palletizing of your products.

Read more about cobot palletizers >Implementing a palletizing system in your production process will increase the efficiency and improve quality of work. A system such as the Smart Palletizer can help with various production challenges such as:

- Growing labor shortage.

- Increasing consumer demand and variety.

- Heavy and repetitive work; employees can focus on tasks that require human skills.

- High sick leave amongst your employees due to physically straining work.

The Smart Palletizer is a cobot system. But why choose a cobot palletizer? A cobot palletizer requires a much smaller space than a robot palletizer and cooperates safely with your employees.

Read more about cobot palletizers >A cobot, or collaborative robot, is a type of robot that can safely work together with both people and other cobots. Compared to the traditional industrial robots, they are more affordable, smaller, can easily be deployed in various processes and are built and programmed to cooperate with people. Hence the name ‘collaborative robot’.

Read more about cobot palletizers >Have another question? Contact us