Table of contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

The top 5 e-commerce fulfillment trends in 2025

Table of contents

The revenue for the e-commerce market is projected to reach almost $5 billion in 2025, a significant jump from $3.5 billion in 2023. And it doesn’t stop there. According to Statista, it’s expected to climb even further, reaching $6.5 billion by 2029. What does that mean for your warehouse and fulfillment centers? And what do you need to know to get in on this revenue and stay ahead of the curve?

Here are the top five e-commerce order fulfillment trends you need to watch for in 2025. With each trend, we’ll share a quick takeaway to help you take action.

Continued e-commerce growth fuels the rise of ‘item-picking’

After being confined indoors during the Covid-19 pandemic of 2020 and 2021, it was no surprise that online shopping surged, accounting for 18.8% of total global sales. What’s surprising, however, is the continued growth in e-commerce sales, which rose to almost 20% in 2023 and is expected to climb to 21% in 2025.

Now, here’s what that means.

Online shopping is still dominant and growing, despite no longer having to stay indoors. Retail brands are doubling down on fulfillment hubs to move inventory more efficiently, rather than sending large pallets of goods directly to shops.

This shift signals the rise of ‘each-picking’, or ‘item-picking’, where quick picking and placing of individual items into shipping cartons to get orders out the door is becoming the backbone of meeting rising consumer demands.

Quick Takeaway

Re-evaluate your warehouse or fulfillment hub’s layout. Is it optimized to prioritize fast-moving items? Are there designated zones for quick picking and packing? You can also consider investing in picking and placing solutions that can process orders around the clock for you. We’ll dive into that in just a minute.

Same-day delivery and micro-fulfillment centers

Order today, delivered tomorrow? That’s a thing of the past. According to a McKinsey study, same-day and instant delivery services are projected to account for a combined market share of 20% to 25% in 2025, with 41% of consumers willing to pay extra for same-day delivery.

With consumers becoming more and more tied to their phones, brands are ultimately competing for screen time. However, if consumers encounter the dreaded ‘long delivery time’ at checkout, 46% are likely to abandon their cart, according to a report by DHL.

Now, how do you solve that?

There are already measures in place to implement micro-fulfillment centers and bring businesses closer to consumers. Online supermarkets like Farmy in Switzerland have converted a wine cellar into a microfulfillment center, significantly speeding up delivery times for their customers.

Similarly, B&Q, a UK-based home improvement retailer, recently transformed parts of its physical stores into micro-fulfillment hubs for online orders, effectively killing two birds with one stone.

Quick Takeaway

Same-day deliveries is not an easy task for any warehouse, and with rising labor shortages, it has become almost impossible. Additionally, not every business has the resources to plan and open new micro-warehouses for faster delivery. That is where robotics and automation come into play.

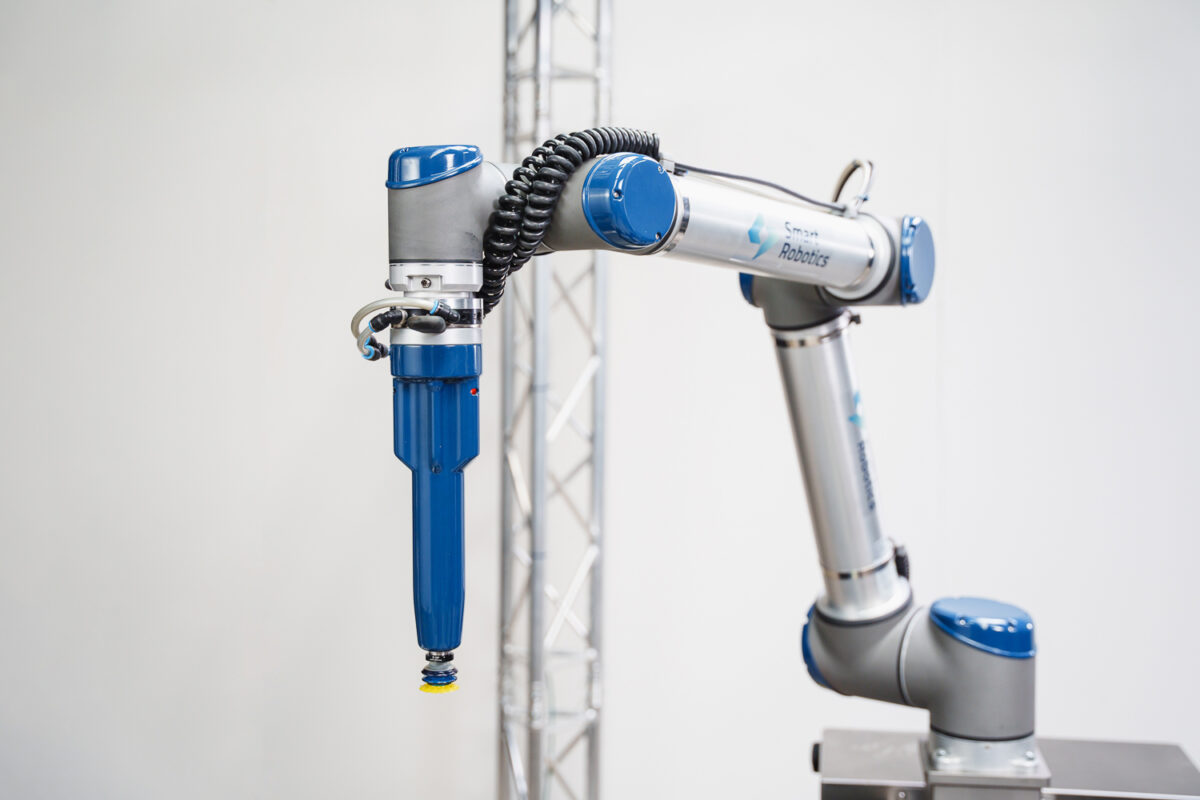

Advanced robotics and automation are at the forefront

We’ve been hearing about robotics and automation transforming warehouses for years now, but now the momentum is stronger than ever. Today, robotic picking solutions can handle up to 1,000 picks per hour—a massive leap compared to the 250–350 picks per hour typically done by human workers.

What does that mean?

By 2025, an estimated 4 million warehouse robots are expected to be installed across 50,000 warehouses worldwide. And according to a study by Interact Analysis, 26% of warehouses are projected to have automation implemented by 2027, up significantly from just 18% at the end of 2021.

So, what’s driving this shift?

There are many factors contributing to these decisions, but most notably are labor shortages paralleled with rising e-commerce.

Quick Takeaway

Take a close look at your warehouse operations. Identify areas where automation could fill the gaps and boost efficiency. Start the conversation—there might be a solution out there that can transform how your warehouse runs. If you’re curious on where you can get started, our warehouse automation experts are here to help you get started.

Personalization in fulfillment

Whether you want to receive your order after work hours or on weekends, retailers are starting to allow customers to personalize their orders. According to a report by PWC, 83% of online shoppers are more likely to share their information and receive a more personalized customer experience.

Aspects like flexible delivery windows, ‘Scan & Collect’ locker hubs, and branded inserts have all been experimented with by many major retailers and warehouses. Best buy, n American consumer electronics retailer, implemented a scheduled delivery service, offering specific days and 2-hour windows that customers can choose from.

Quick Takeaway

A very simple way to personalize a customer’s experience is by giving them order updates. That can easily be done by sending real-time notifications via email, SMS, or app alerts. If you want to give your customers the option to personalize their delivery times, your warehouse needs to have automation set up to make that promise a reality.

Ask yourself – Do you have the right technology in place to deliver personalized customer experiences? Have you invested time & resources into making your warehouse efficient? Take a moment to reflect.

AI-powered forecasting and inventory management

Knowing when to expect a surge in demand or a drop in sales can make a big difference in how a warehouse runs. Warehouses that use this kind of technology are seeing huge benefits. Take Amazon, for example. Their AI-powered forecasting tools look at customer behavior, past data, and market trends to predict when demand will rise or fall. This helps them manage inventory better, cut storage costs, and restock on time, giving them a big advantage in efficiency and keeping customers happy.

Quick Takeaway

Knowing when demand will spike or sales will dip can give your warehouse a significant edge. Amazon’s success comes from using AI to predict trends, manage stock efficiently, and save on costs. And any business, at every scale, could use AI and automation solutions to make their businesses run more efficiently.

Conclusion

Now some of these trends have already started in the past years, but 2025 is taking these trends to new levels. From the rise of same-day delivery to the increased power of robotics & AI, the consumers are starting to ask for more and businesses are expected to deliver.

By taking proactive steps—whether that’s adopting new technology or rethinking your processes— you can ensure your operations are ready for the future. The time to act is now.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Boost your order fulfillment efficiency with the Smart Item PickerLearn More

Download our free white paper

Learn how to implement the ideal pick & place robot in your warehouse. Leave your contact details and receive a download link to our free white paper.