Table of Contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

5 ways mixed case palletizing is reshaping the supply chain

Table of Contents

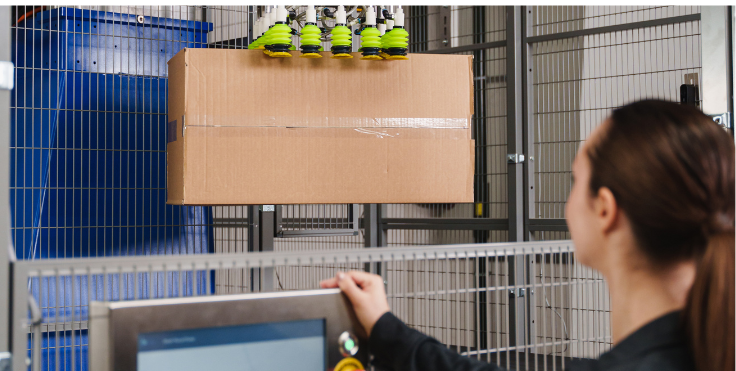

Stacking cases of different sizes and weights onto a pallet can be a challenging task to accomplish. It’s almost like playing real-life Tetris – although it can be fun and challenging, people naturally need to slow down and think: what to stack when, and where? That costs businesses money. That’s where automated mixed case palletizing comes in.

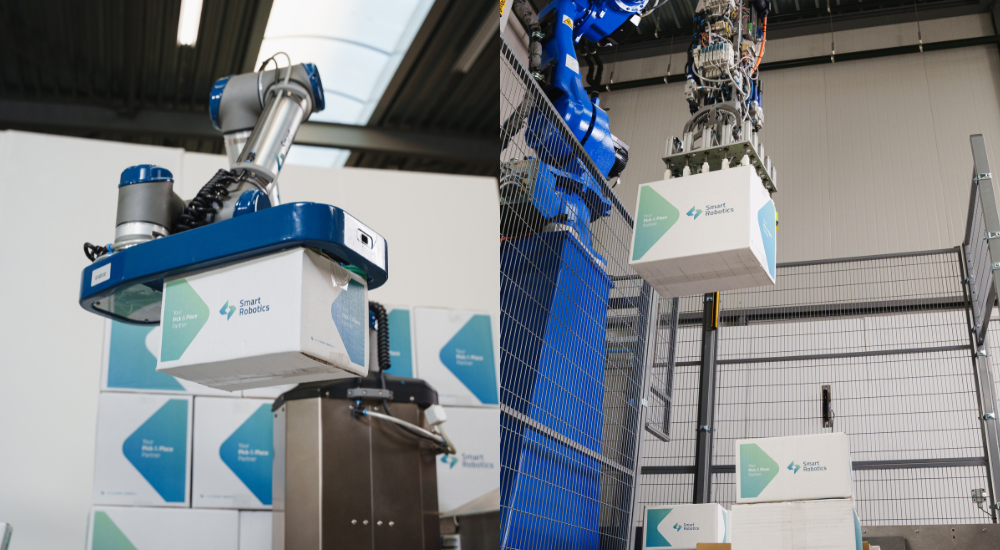

Mixed case palletizers speed things up by using AI and intelligent sensors to stack mixed cases faster and more consistently than any operator can.

In this blog, we’ll give you a deep dive into 5 ways mixed case palletizing is helping improve the overall supply chain, starting with:

1. Boosting end-of-line efficiency

Operators manually palletizing mixed cases constantly have to think about how to place each case to keep the pallet stable and use space efficiently. On the other hand, robotic mixed case palletizers use AI to process data and make quick stacking decisions. The software instantly calculates the optimal stacking pattern – much faster and more consistently than a human can.

This not only speeds up the workflow, but also reduces downtime caused by fatigue or errors — getting goods out the door faster and keeping customers happy.

2. Cutting down the number of lines you need

Most palletizing setups keep lines separate so that each one handles products of the same size and weight.

Thanks to mixed case palletizers, facilities can run a single line of different products – not worrying about the weight or size.

Having just one (or only a few) line(s) running products with different sizes and weights dramatically reduces costs of infrastructure, maintenance, and overall footprint.

3. Reducing labor strain and injury risk

Manually palletizing mixed cases often means repetitive lifting, sometimes in awkward ways. That adds up and can take a toll on workers over time, especially when lifting heavy cases over the head.

Mixed case palletizers come in to take over the heavy, repetitive work, helping reduce the risk of injuries on the floor. This doesn’t just improve worker safety; it also helps companies comply with the new strict EHS regulations, especially in Europe.

4. Keeping pallets stable during transport

When a pallet travels long distances, you want to make sure it’s stable enough for the journey. Mixed case palletizers don’t just make decisions based on size, they also consider box weight and fragility to build a balanced pallet.

This lowers the risk of damage during transit and helps prevent pallets collapsing on the warehouse floor.

5. Increasing flexibility for retail and e-commerce

A T-shirt, sunscreen, and a pen, all in the same order? These days, that’s the norm.

Retail and e-commerce orders are getting smaller, more frequent, and more varied. Mixed case palletizers make it easy to stack different SKUs on the same pallet, so there’s no need for separate lines or setups.

Whether it’s beverages, snacks, or electronic products, mixed case palletizers adapts to different product sizes and stacking patterns on the fly.

Key takeaway

Mixed case palletizing brings real, measurable improvements to warehouse operations. It reduces the number of lines needed, lowers your footprint, and cuts infrastructure costs, all while increasing throughput and overall output.

No surprise, then, that more and more facilities are choosing mixed case palletizers over traditional single-SKU systems.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

FAQs

Mixed case palletizing is an automated process where robotic systems stack cases of varying sizes, weights, and contents onto the same pallet. These systems use artificial intelligence, sensors, and vision technology to calculate the most stable and space-efficient stacking pattern, enabling pallets to get out the door fast.

Key advantages of mixed case palletizing in supply chain include:

- Increased throughput by automating complex stacking tasks

- Reduced labor dependency and improved workplace safety

- Higher pallet stability during transport

- In some cases, less floor space needed is needed thanks to line consolidation

- Greater flexibility, especially for e-commerce and retail fulfillment

By enabling a single robotic system to stack multiple product SKUs from the same line onto one pallet, companies can reduce downtime, eliminate manual stacking errors, and streamline end-of-line operations.

Yes. Mixed case systems eliminate the need for multiple product-specific palletizing lines, saving on equipment, maintenance, and floor space. Over time, this contributes to a lower total cost of ownership (TCO) for automation.

Absolutely. These industries often deal with high product variety and smaller, more frequent orders. Mixed case palletizers adapt quickly to SKU changes and handle a wide range of package types, perfect for modern omnichannel supply chains.

Curious About Introducing Mixed Case Palletizers in Your Facility?Get Started Today