Table of contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Automated Warehouses

Table of contents

Addressing the labour shortage in logistics

- The labour shortage in logistics is growing and so is the need for automation in warehousing.

- Picking automation relieves warehouse employees from time-consuming and physically straining tasks.

Since mid 2021, it’s been prominently noted that the global logistics industry is experiencing great labour shortages, across all sectors. With talent shortages among skilled and unskilled professionals, vacancies in logistics are at an all time high. The warehousing sector has felt the effects of the labour crisis, firsthand, and with parcel handling at the core of business, it is critical to ensure improvements are made so that the lack of employees does not set back operation efficiency.

Warehouse automation does however not mean replacing employees with machines or robots, it simply means certain automation, requiring minimal human assistance, are introduced in the warehouse. For example, picking automation relieves warehouse employees from time consuming and physically demanding tasks. This type of automation allows existing employees to spend less time manually picking and sorting parcels, as well as speeding up the time it takes to complete the activity. With little human labour involved, picking automation creates a highly functional environment in the warehouse where employees and robots can co-exist.

Want to know more about warehouse automation? Discover how our robotic Pick & Place solutions can transform your order fulfillment and warehouse operations, boosting production efficiency and accuracy.

More to gain from warehouse automation

As we’ve seen across industries in a post-pandemic era, fundamentally, employees want more to gain from their work environments. Even more so when not being able to work from home. This is especially the case in warehousing – with flexible work arrangements not being an option, as with many sectors in logistics.

As a result of the demand for better working conditions in warehouses, companies are now faced with the challenge of catering to the needs of their employees whilst keeping labour costs at an affordable rate.

One solution to improving labour efficiency in warehouses is by introducing picking automation as a service. Not only does picking automation fill a gap in the process efficiency of floorwork in the warehouse, but it grants warehouse employees the opportunity to focus their attention on where their skillsets are needed with greater urgency.

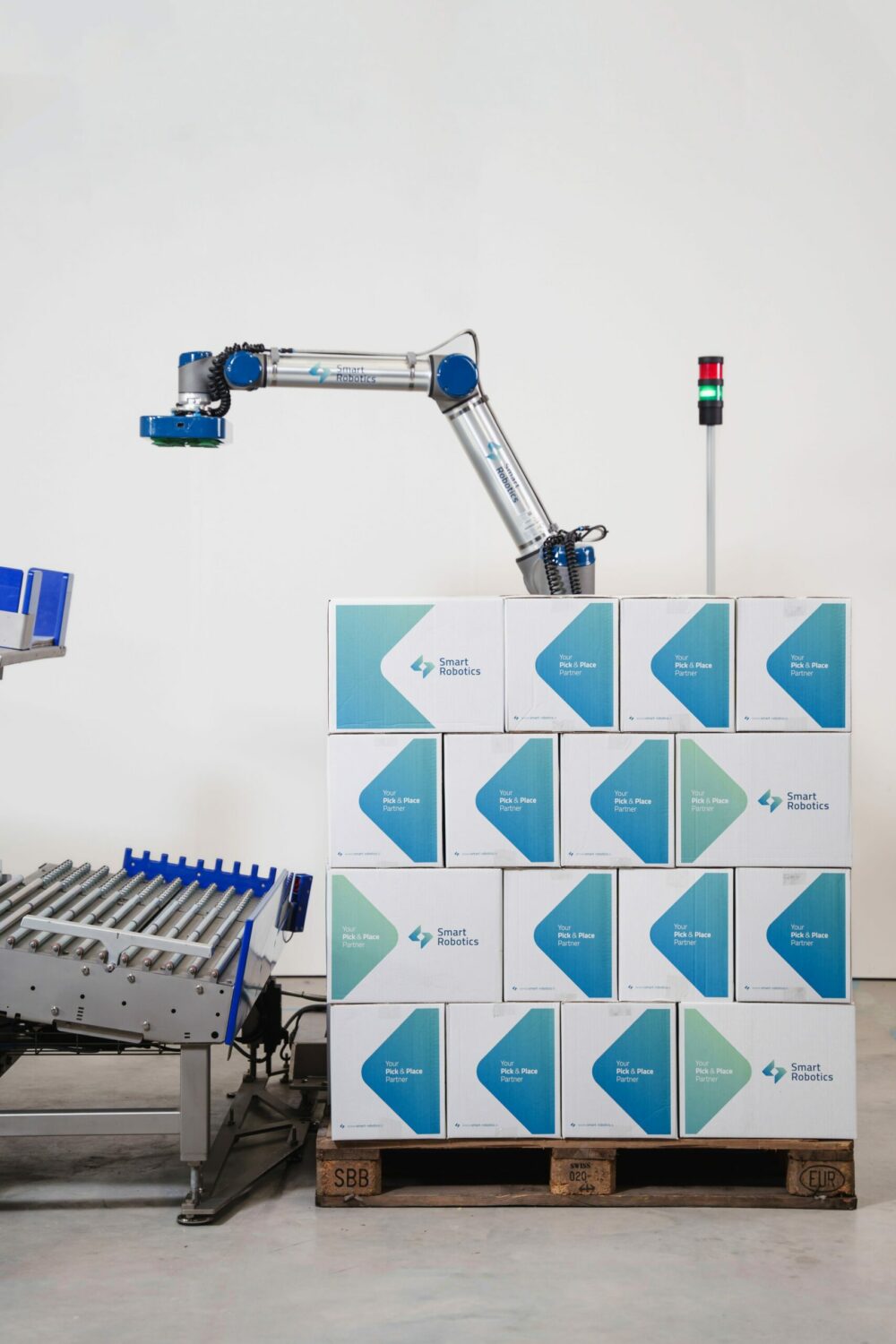

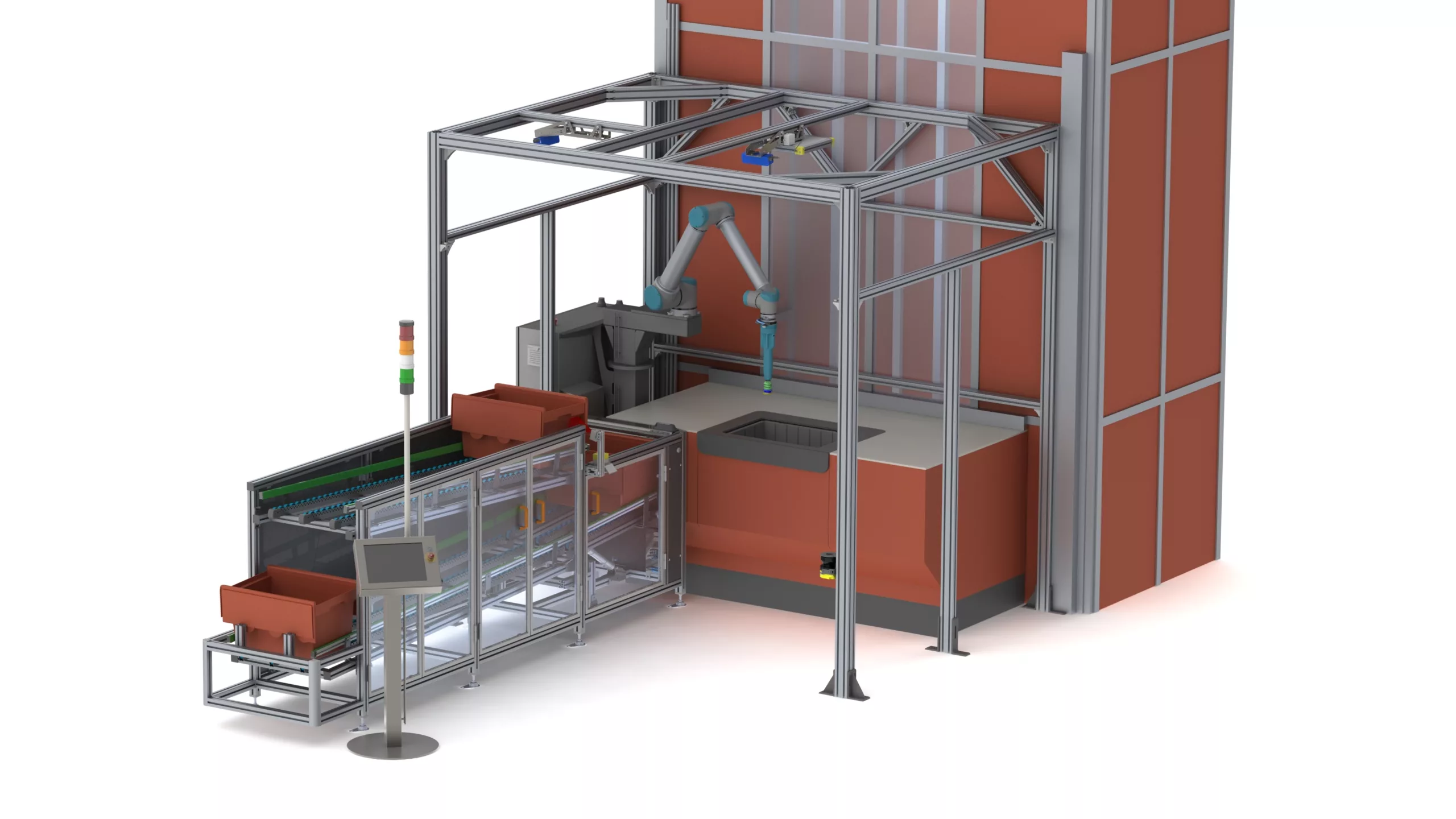

Picking automation refers to the utilisation of robotic arms in the warehouse to “pick and place” items with greater efficiency. This type of automation can help overcome the labour need in the warehousing sector, as well as help scale up production by automating tasks that are repetitive and physically demanding.

Picking automation, coupled with the advancements of AI software, is transforming production lines by improving accuracy and operational efficiency. With an ever increasing consumer demand for retail efficiency, for example, the expectation of same day delivery, the logistics industry cannot afford the setback of a labour shortage against customer demand.

Besides customer demand being strenuous on the logistics industry’s capabilities of delivering on customer expectations, the added pressure to perform optimally results in mental and physical strains impacting employees. Therefore, automating the warehouse and production is key in relieving warehouse employees from time consuming and physically straining tasks.

By automating specific sections of the warehouse’s operations, such as picking and stacking groups of parcels, efficiency and performance improvement is achieved – based on the principle that manual labour is swapped with automated processes.

New opportunities created by automation in the warehouse

By introducing robotic automation in the warehouse, warehouses of the future will be able to handle more materials and will require less physical labour input to get tasks done. By automating manual processes, greater operational efficiency is achieved.

Improving manual processes in the warehouse

Often, processes like parcel picking and stacking require a great deal of physical effort. Not only does this place strain on the employees’ physical health, mental wellbeing is often undermined by the pressure to maximise operational productivity. Robotic automation should however be viewed as tools to improve the existing capabilities of warehouse employees and to help processes move faster, with more precision.

Warehouse automation should be carefully strategised, so as to keep a healthy balance between human and robotic collaborations. Collaborative-robots (cobots) are smaller robots designed specifically to maintain this balance. These types of robots are easy to engage with and safe to be around. Next to this, they don’t take up much floor space in the warehouse. For example, cobots designed for stacking smaller parcels saves employees walking and sorting time.

Improving quality of work

When pursuing automation in the warehouse, a critical factor to note is that robotics aims to relieve existing employees from repetitive and physically straining work, granting them time to focus on tasks that require human skills. The goal is not to replace human talent, automation exists to help solve specific problems – without taking away from employees’ workplace quality and standard of work. The goal is to benefit human performance, productivity and working conditions, for example, by cutting back on walking time or heavy lifting in the warehouse.

Level of expertise

The future of warehousing is to a great extent reliant on robotics and automation. However, employees, no matter their level of experience with robotics, need to be able to operate and interact with robots. In order to achieve optimal performance improvement in the warehouse, robotics need to be made accessible to everyone. This means that robotics or automated processes should not be complicated to oversee or to manage by anyone, no matter their technical background, prior experience or knowledge about robotics.

Reliability of automation

Staying with the example of cobots, robotic automations have become quite sophisticated in design. Intelligent vision, motion and task planning algorithms now enable cobots to handle a large variety of items whilst safely cooperating with employees. Little human involvement is needed when the cobot runs into an error, for example, redirecting its movements or readjusting its position in relation to the packages it is stacking.

Key challenge of warehouse automation

A key challenge in implementing automation in the warehouse is change management. When trading physical labour for robotic automation, there are multiple business processes and workflows that need to be rewritten. This also requires management to think about the existing infrastructure of the warehouse to accommodate a certain level of automation.

When designing new systems and processes to accommodate automated functions, the use of space and labour constraints need to be considered. This is important in order to maintain a balanced working environment and to ensure that the warehouse’s functionality and productivity is indeed improved. Not to mention the accuracy with which tasks are performed. It is therefore important to prioritise which manual activities can be exchanged for robotic automation – to aid the employees in their tasks and to lessen the dependency on physical labour.

In conclusion, companies will need to continue adapting and responding to the changing wants and needs of their workforce. Proactivity and a more profound understanding of what is important in the warehouse environment will be a key strategy in the future to avoid the shortages seen in today’s market. It is however important to keep in mind that robotic automation cannot replace the manual workforce. The aim is to simplify and ease the demand of employees, whilst creating better working conditions for those engaging in physical labour activities across logistics.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Download our free white paper

Learn how to implement the ideal pick & place robot in your warehouse. Leave your contact details and receive a download link to our free whitepaper.