Table of contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Robotics beyond cost benefits

Table of contents

The warehousing industry has seen a supercharged demand for faster response times, and around-the-clock delivery, especially with the growth of e-commerce. This resulted in supply chains having to constantly keep up with the rise in demands. In turn, the warehousing industry had to accommodate capital efficiency against a growing global labour shortage. Not to mention, having to optimise capacity and operations efficiency.

However, specifically for the market in India, the availability and cost of labour did not have as great an impact on warehouses’ efficiency, as it did in other corners of the globe. Despite labour shortages not being a challenge in this market, under unique circumstances, it is not always possible for warehouse employees to optimally utilise their time and capacity to conduct their daily tasks. Especially tasks that require physical labour, such as parcel picking, sorting, and palletizing and depalletizing.

Due to heightened levels of pressure, stemming from changes in consumer behaviour, supply and demand has caused working conditions to be less favourable towards supporting effective manual labour. In the case where warehousing infrastructure cannot support the physical wellbeing of employees conducting manual tasks, automation should be regarded as a valuable solution for warehouse optimization and to protect the health and safety of employees.

Automation and robotics in this context

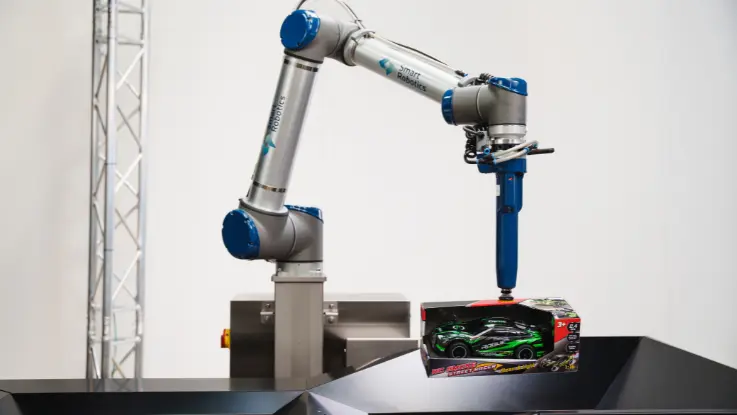

Historically, reducing costs has certainly been one of the biggest motivators and incentives for automation. In warehouse operations, the pick and place processes contribute as much as 55% of the total operational expense. To reduce operational cost and to increase warehouse efficiency, companies should focus on optimising these processes before they fall too far behind the supply and demand of the greater market.

Though, as the fourth industrial revolution is being ushered in, a notable shift in incentives for automation is apparent. The focus is no longer solely on automation for lower capital expenses, but incorporates the desire for better physical workfloor conditions across warehouses.

As mentioned, the primary motivation for introducing automation into the warehouse was to save operational costs, however, the benefits of automation stretch beyond cutting back on company expenses. The reasons for automation have changed dramatically. The motivation for automation is no longer to save capital and resources, but to improve speed and dependability.

Not only does automation speedup productivity, the mental and physical well-being of employees improve as robotic systems take over repetitive and strenuous tasks. Robotics have the unique potential to assist the human workforce’s performance by improving the quality of experience for the workforce. Instead of conducting time consuming and repetitive tasks, employees can rather dedicate their efforts towards learning how to manage robots in the warehouse. When these systems are implemented correctly, it grants employees the time to learn a more sophisticated skill set, whilst robots take care of repetitive tasks.

Health and safety in a particularly hazardous work environment

Considering the health and safety of employees, automation solves ergonomic challenges that develop over time. Risks are particularly high in traditional facilities where employees pick and prepare orders manually. Employees can spend a large portion of their day performing strenuous tasks (running up and down aisles, bending and reaching to retrieve goods, moving products in and out of storage, loading pallets, lifting heavy crates and boxes, etc.). These activities put considerable tension on muscles, joints, tendons and nerves.

While some injuries are minor, like sprains and pulled muscles, there are risks that lead to serious, long-term issues. These conditions – such as repetitive stress injuries, repetitive motion injuries, musculoskeletal disorders, cumulative trauma disorders, and cumulative trauma injuries – can mean a lifetime of chronic pain.

This is where robotics become a viable option to solve very human problems. Looking at the evolution of robotics, robots are now being designed to co-exist with employees and interact with them on a daily basis. Robots are now collaborating with employees and taking over repetitive tasks that mitigate risks and injuries.

Optimising the work environment

To address rising health and safety concerns, optimising warehouse infrastructure can greatly minimise health and safety risks and lead to long-term benefits that enhance employee well-being in the workplace.

Some options include tailor-made robotic systems to seamlessly integrate with existing warehouse infrastructure. This way little disruption is caused in terms of the physical environment. Robots are also becoming smaller and smarter, further reducing potential injuries caused by robotic systems. Collaborative robots (cobots), can work in close proximity with warehouse employees. In some cases, it’s even possible to make physical contact with the cobot as part of their normal functions and since most cobots models have built-in safety controls to prevent hazardous contact, safety is guaranteed to a greater degree.

On the front of optimising work performance for better health and safety, expectations are redefined when it comes to the accuracy and agility against which robotic systems operate. Taking into account the strenuous tasks warehouse employees perform when moving large goods, robots can handle a large variety of objects whilst replacing the rigid activities for employees.

Although robotic systems can be designed to integrate with the physical environment it finds itself in, some warehouses still demand a significant degree of flexibility to accommodate new processes. As a response to this, new technologies have developed to the point where warehouses don’t have to be designed around the robots, but the robots can be built to operate on the warehouses’ terms instead. With new technologies constantly emerging, robot designs are becoming more humancentric, contributing to the promise of reducing occupational health and safety risks that form part of the robotised workplace structure.

How to make the best of this technology?

If warehouses want to optimise the efficiency of their workforce, and the efforts that go towards working cooperatively with robotics, robotic integrations in the warehouse need to happen as seamlessly as possible. This also means that the automated systems have to be easy to use, not requiring employees to have a background in working with robotics previously.

Alongside easy to integrate robotics, employees need to undergo proper training in a proactive manner. This ensures greater confidence that employees can efficiently collaborate with the new robotic systems.

The designs of robotic systems are also becoming more easy-to-use, some robots are fully autonomous – requiring almost no human input to operate. Though, where a robot cannot recalibrate or correct itself, employees should be empowered to problem solve and help the robot reset. This is only possible with the proper training models in place.

What does the future look like for warehouse automation/handling?

The goal is mechanical orchestration, in which a team of robots, steered by sophisticated software and artificial intelligence, can move boxes and products in a seamless environment. This does not mean that robots will replace humans, but rather complement and enhance their skills instead. As is expected, the adoption of robotics in warehouses will globally increase by 50% or more in the next five years, according to surveys taken by the Material Handling Institute, an industry trade group.

As more fulfilment centres are moving towards becoming a ‘smart warehouse’, prioritising areas of improvement is key in creating an optimised warehouse. Staying flexible and focusing on resource productivity and efficiency is one of the best practices in creating valuable, career enhancing opportunities for employees, whilst aiming to leverage smart technologies.

As warehouses move from manual to automated processes, data mitigation will require a heightened level of attention. Creating a smart warehouse therefore demands a strategic, regulatory framework to deploy logistics at scale, as well as asks for the standardisation of interfaces and harmonising business processes.

These factors cannot be overlooked when planning for the future, as smart warehouses essentially reduce employee time spent on physically and mentally draining tasks, as well as eliminating non-ergonomic, repetitive work done by humans. Thus, the future of warehouse automation is set on boosting human productivity and developing their capacity to quickly pick up critical skills and adapt to the constantly changing demands of the workplace.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Download our free white paper

Learn how to implement the ideal pick & place robot in your warehouse. Leave your contact details and receive a download link to our free whitepaper.

Please select a valid form.