Smart Mixed Case Palletizer For Mixed SKUs

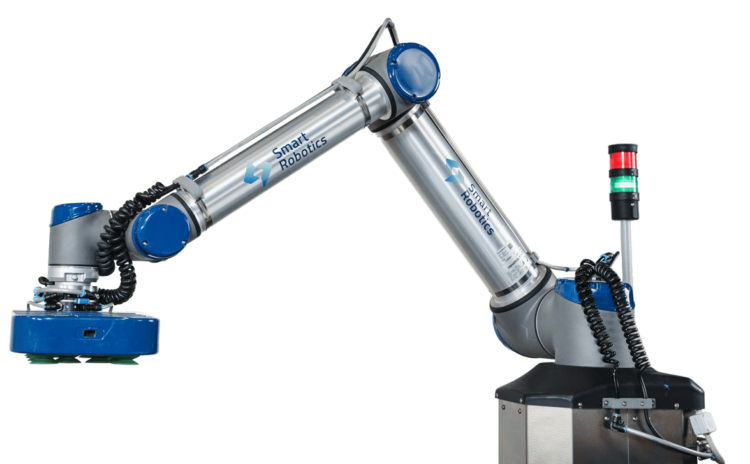

Boost your outbound process to reach faster delivery with the Smart Mixed Case Palletizer, our next-generation palletizing solution for stable and efficient palletizing of different products.

Automated mixed case palletizing

Our AI-powered mixed case palletizing solution helps industries like food and beverage, pharma, retail, parcel, and 3PL optimize their end-of-line process. It also ensures products are stacked for maximum volume and stability – prepared for shipment.

The Smart Mixed Case Palletizer is designed to overcome the following challenges:

- Growing labor shortages whilst dealing with ever-growing consumer demand

- The need for an improved pre-sortation process without increasing FTEs

- The need for efficiency and saving time to reach faster delivery

- Growing need to comply with strict health and safety legislation

- Dissatisfied employees and high turnover rate due to dull, repetitive and physically straining work

Food

Retail

Pharma

Parcels

Top Features

High Throughput

Stacks upto 500 items/hour

AI Palletizing

AI determines the optimal position for volume & stability

Stacking Stability

Stacks heavy & light items over 2 meters while ensuring stability

Gentle Item Handling

Minimizes the risk of item damage during the process

Smart Mixed Case Palletizer Benefits

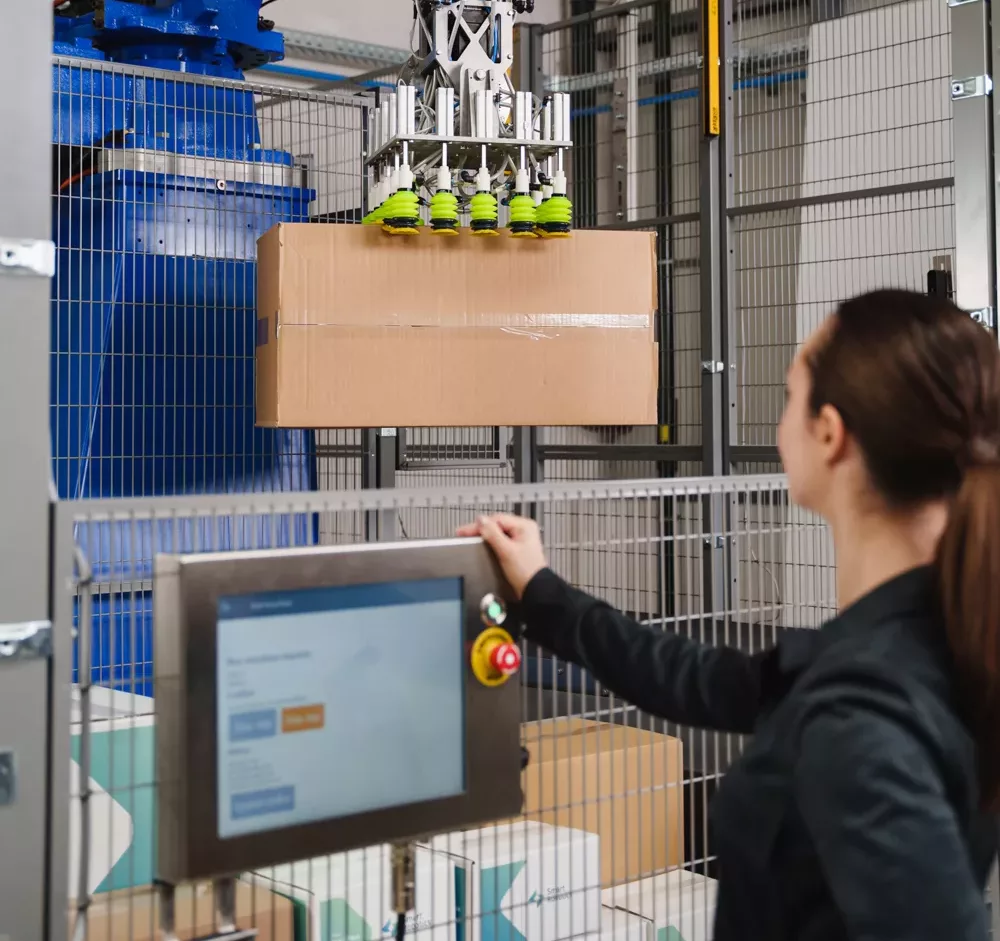

The benefits include increased efficiency, improved health and safety of employees, and reduced labor costs. Palletizing solutions can be customized to meet the specific needs of a variety of industries and businesses.

High level of performance & reliability

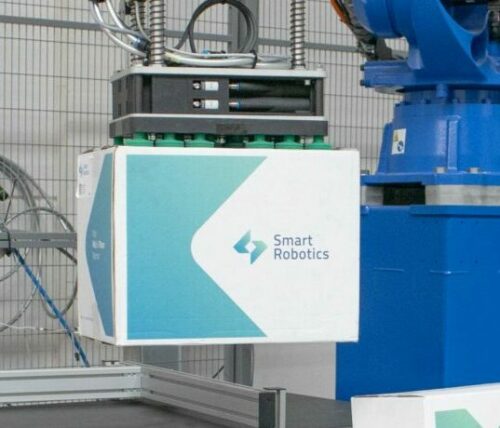

The system handles a large variety of mixed cases without the need for SKU teaching. Its user-friendly design ensures that any operator can easily manage the system. Our remote reporting ensures reliable performance across your operations, minimizing downtime and boosting productivity.

High level of learning & adaptability

Powered by AI, the Smart Mixed Case Palletizer automatically adjusts to the workflow so there is no need to pre-calculate the stacking sequences, the system continuously learns and adapts to improve efficiency and responsiveness.

High level of flexibility & scalability

Easy integration into your WMS without complex installation. It determines the stacking pattern on the fly. This solution can also reduce steps in your sortation process due to more effective pre-sortation. As your operation grows, the system scales easily to meet increased demand and maintain efficiency.

High level of service & ROI

We offer picking automation as a service: hardware, software and service included. Our Online Helpdesk and dedicated customer service team ensure fast issue resolution and maintenance, providing continuous operation and a strong return on investment.

Optimize your outbound process

Watch video

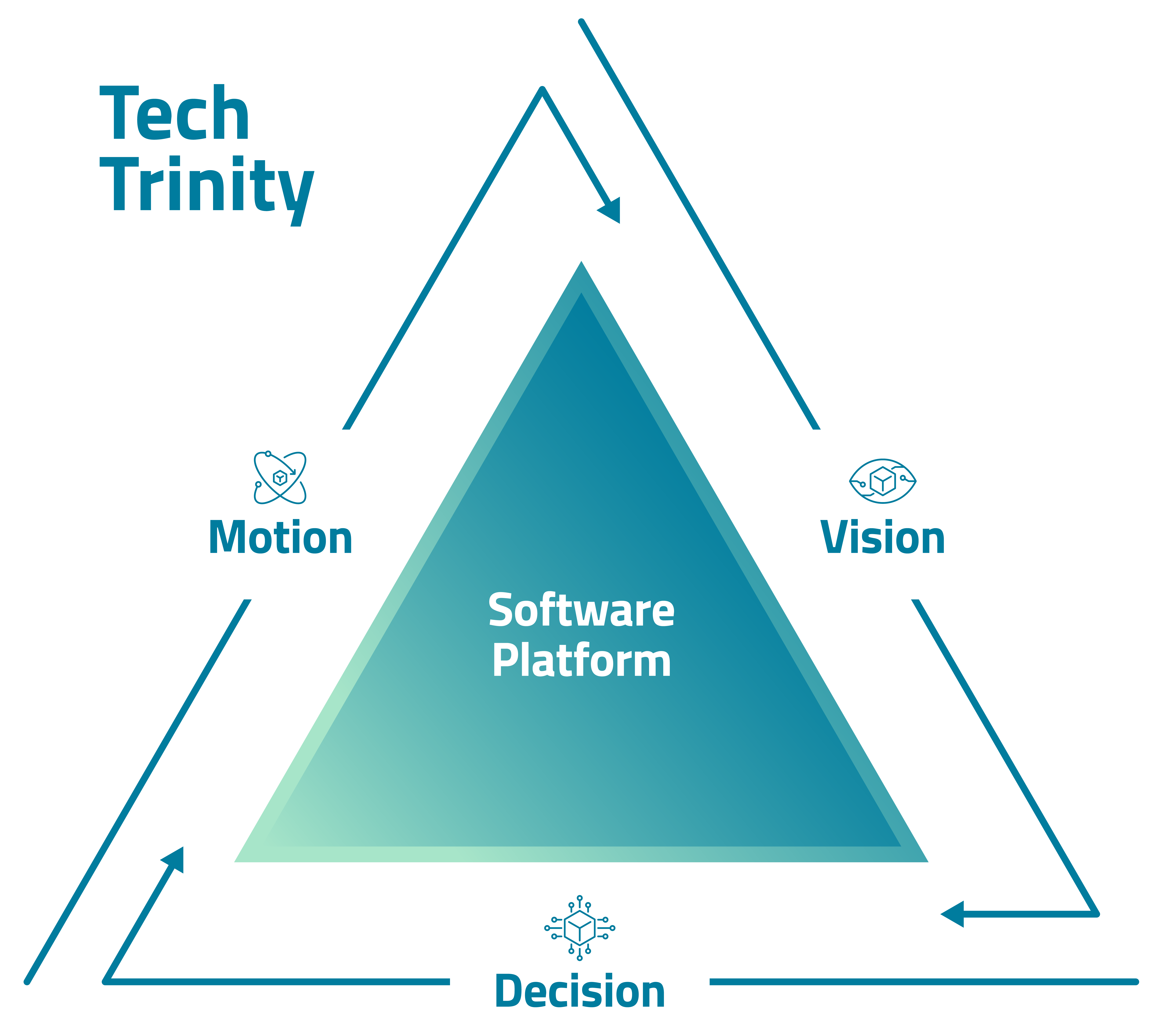

AI Vision Motion and Decision

With our Technology Trinity, the Smart Mixed Case Palletizer determines each pick and place action on the fly, resulting in greater flexibility and easy integration in your WMS. Our AI software learns and adapts continuously to improve efficiency and productivity. The intelligent core of our solution powered by vision, motion and decision-making algorithms ensures high accuracy, volume and stability. The integration of this system optimizes your warehouse operations, delivering a smarter palletizing system that enables you to increase your warehouse capacity and achieve delivery times.

Download our free whitepaper

Looking for more information? Learn about full potential of your warehouse automation strategy by downloading our whitepaper, Strategic Automation: A guide to implementing Robotics in Warehouse Operations before you make the next step. Leave your contact details and receive a download link to the whitepaper for free!

FAQ

Smart Mixed Case Palletizer

The Smart Mixed Case Palletizer is an automated machine or robotic system designed to stack different types of cases or products on a pallet in an organized and efficient way for shipping. Designed for flexibility, it easily integrates into existing workflows, making it ideal for businesses looking to automate their palletizing process.

The Smart Mixed Case Palletizer uses AI to efficiently stack mixed SKUs onto pallets which means it does not rely on a predetermined stacking pattern. With its intelligent vision, motion and decision-making algorithms, it identifies each item and determines the optimal placement for stability. The robotic gripper can handle items weighing up to 30kg and stack them up to 2 meters high, ensuring accuracy and stability. Operating at speeds of up to 500 items per hour, it significantly boosts productivity with minimal human intervention.

It is ideal for warehouses or distribution centers in logistics where pallets contain multiple products, often to fulfil orders that require a range of items. Mixed case palletizing ensures that mixed SKUs are efficiently organized and prepared for shipment, making it highly useful in industries like retail, food, parcel logistics and more.

Boost your throughput with the Smart Mixed Case Palletizer