Table of Contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

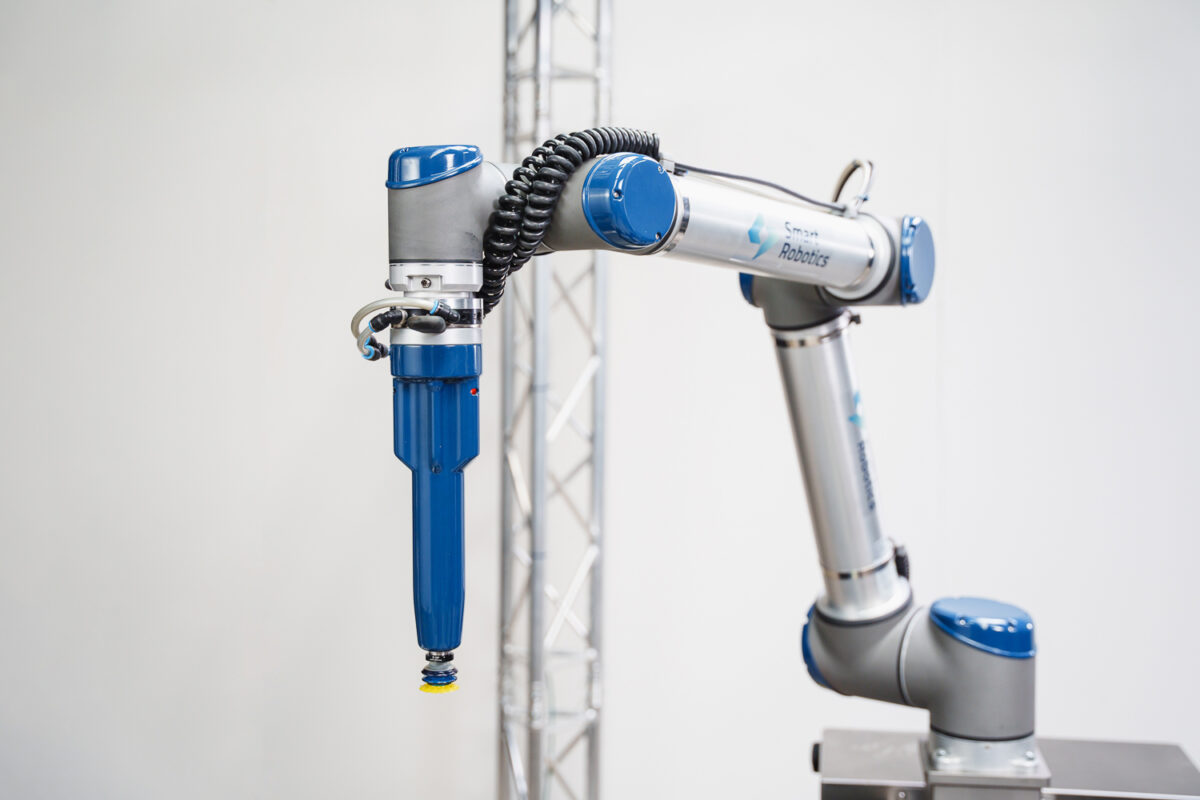

What are end-effectors? Types and applications of end-effectors

Table of Contents

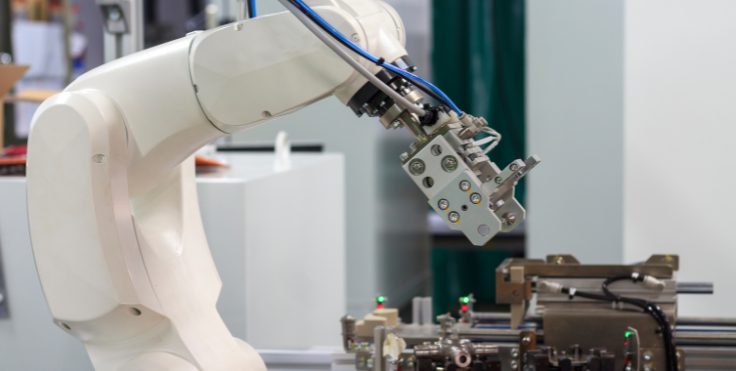

An end-effector is the tool that sits right at the end of a robotic arm, basically, the robot’s hand. It’s what allows the robot to interact with its surroundings. Whether it’s gripping, placing, welding, or scanning, this is the part allows the action to be fulfilled. For example, in a pick-and-place setup, the end-effector needs to grab an item, hold it securely, and place it exactly where it needs to go.

Automation is taking over many repetitive, and often dangerous, tasks today. Moreover, the number of end-effectors available now is likely in the hundreds, and it’s still growing. End-effectors are getting smarter, more specialized, and more adaptive each year.

With that in mind, here’s everything you need to know about the various types of end-effectors: how they work and the role they play in industrial automation.

What are the types of end-effectors used in robots?

End-effectors generally fall into three main categories: grippers, process tools, and sensors. The choice between them depends heavily on the application.

Pick-and-place tasks usually require a type of gripper, while process tools are used in tasks like welding or painting. In fast-moving or unpredictable environments, sensors often help end-effectors perform their jobs better.

End-effector grippers

Mechanical Grippers – These are finger-like grippers, similar to how a human would pick up an object. They’re widely used in sorting and assembly applications, moving products from one place to another.

- Note: Mechanical grippers are simple, reliable, and cost-effective but may not be suitable for handling irregularly shaped objects.

Vacuum Grippers – Using suction cups and vacuum air, these grippers securely lift products. They became popular after mechanical grippers, especially in industries looking for faster cycle times and greater versatility. Applications like palletizing, depalletizing, and item picking all rely on vacuum grippers.

- Note: Vacuum grippers are easy to use, highly reliable, and have a fast cycle time but may not be suitable for handling heavy or non-porous objects.

Magnetic Grippers – These grippers use magnetic fields to lift and transport metal parts. As industries like automotive and metalworking expanded, magnetic grippers became essential for handling ferrous materials quickly and safely—while minimizing the risk of scratches or damage.

- Note: Magnetic grippers are highly reliable and require minimal maintenance but may not be suitable for handling non-ferromagnetic materials.

Servo Grippers – Unlike traditional open/close grippers, servo grippers allow precise control over grip position and force. This makes them ideal for handling delicate or varied objects, such as soft packaging, electronics, or glassware.

- Note: Servo grippers are highly precise and flexible but may be more expensive and require more complex control systems.

Each type of gripper comes with its strengths and trade-offs. Choosing the right one depends on the object being handled, the required speed and precision, and the work environment.

Sensors in end-effectors

Without sensors, an end-effector is essentially a blind tool—only capable of repeating pre-programmed movements. But with sensors, robots gain the ability to react to their environment and make decisions on the fly. Sensors are particularly valuable in unstructured or constantly changing environments.

Here are the most commonly used sensor types:

Vision Sensors – These sensors use cameras and 3D scanners to provide the end-effector with critical visual feedback—such as where to move, what to pick (if applicable), and how the object is oriented. They’re also essential for navigating environments without causing collisions. This makes vision sensors crucial for any application that requires precise positioning and manipulation, like pick-and-place tasks.

Proximity Sensors – These help detect how close or far an object is. That gives the robot the ability to pause or adjust if it’s nearing a restricted zone, and improves positioning alongside vision data.

Force/Torque Sensors – These are often integrated into end-effectors to measure how much force is being applied during a task. This is essential for handling delicate objects without causing damage and for performing tasks that require a precise amount of pressure.

Light Sensors – While not as common as vision systems, light sensors can support alignment and positioning. They detect changes in light or surface marks, helpful in environments with low visibility or where edge detection is needed.

Magnetic Sensors – These detect magnetic fields and are often used in metal handling or position tracking. They’re especially useful where other sensors might struggle in dusty or low-light settings.

Range Sensors – These measure the distance between the end-effector and nearby objects. That’s useful for collision avoidance, positioning, or path correction.

Applications of end effectors

Many tasks, especially those that are repetitive, hazardous, or tedious, can be automated using robots equipped with end-effectors.

Manufacturing – End-effectors are used across manufacturing—from assembly tasks using mechanical grippers to material handling using suction cups. For example, robotic arms with process tools like welders or drills take over hazardous jobs and leave safe tasks for human workers.

Food and Beverage Industry – End-effectors are essential in automating packaging, sorting, palletizing, and depalletizing. With the right sensors and grip strength, they can handle fragile or perishable items without damaging them. This is key for ensuring product quality and food safety.

Healthcare – In industries like pharma, end-effectors handle tasks such as packaging medication or preparing doses with high precision, eliminating the risk of human error. In surgical or rehabilitation settings, robotic tools support patients with mobility exercises and help them get back on track.

Agriculture – Traditionally done by farm workers, tasks like harvesting, plant care, and seeding are now being automated using end-effectors designed specifically for agriculture. These tools often include grippers and cutting mechanisms that gently handle fruits and vegetables without causing damage. With built-in vision and sensor guidance, they ensure crops are picked efficiently and with care.

Construction – In construction, end-effectors are used to automate tasks that are usually hazardous, such as bricklaying, welding, drilling, and material handling.

Robotic systems equipped with custom grippers or suction cups can lift heavy building materials like concrete blocks, glass panels, or steel beams and place them with precision. These tools increase safety, reduce manual strain, and ensure consistent quality on construction sites.

Logistics – End-effectors are at the core of modern warehouse automation. Whether it’s picking products off shelves, placing items into bins, or palletizing boxes, grippers (especially vacuum-based) speed up processes and reduce human strain.

Automotive – Robotic systems in automotive rely heavily on end-effectors for precision assembly. They’re used to weld car frames, install components like windshields, and lift heavy parts of a car. Depending on the task, end-effectors range from magnetic grippers to welding torches.

How to choose the right end effector?

When picking the right end-effector, it all comes down to what the robot needs to do and how it needs to do it. Here’s what to keep in mind:

Task requirements: Start with the basics. What task do you need the robot to perform? Picking, placing, welding, sorting? What’s the required speed and level of precision? The answers will help you narrow down your options.

End-effector capabilities: Once you’re clear on what the end-effector needs to do, start looking into which tool best fits the task. For example, if you’re automating a palletizing process, a vacuum gripper is a great choice for sealed or taped cases—but it won’t work well for crates or open boxes.

Want to talk it through with automation experts? Book a call with us today.

Compatibility with the robotic system: The end-effector needs to integrate seamlessly with your robot—mechanically, electrically, and through the control software. There’s no value in choosing a great end-effector if it doesn’t communicate properly with your setup.

At Smart Robotics, we deliver complete solutions, including the robotic arm, software, frame, and end-effector integration, so you can leave that part to us.

Maintenance and repair: Choose an end-effector that is both reliable and easy to maintain. Downtime on a production line or in a warehouse quickly translates to lost time and revenue, so durability and ease of servicing are key.

Many systems don’t offer much support after installation, but at Smart Robotics, we do. Our service team is available for everything from remote diagnostics to on-site troubleshooting, so you’re never left without help when you need it.

Cost: When selecting an end-effector, it’s important to look beyond the upfront price and consider the overall value it brings. Think about how well it performs, how long it will last, and what additional components might be needed for integration.

Also factor in the cost of installation, daily operation, maintenance, and the potential impact of downtime. The right end-effector should deliver consistent, long-term value—not just a lower initial cost.

In short

End-effectors may be just one part of your automation system, but they play one of the most critical roles. From precise placement in high-speed palletizing to delicate handling in agriculture or pharma, the right end-effector determines how effective (and reliable) your automation really is.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

FAQs on end-effectors

End-effector types typically fall into one of the three categories: grippers (like mechanical or vacuum grippers), process tools (such as welders or screwdrivers), and sensors (like vision or force sensors).

Start with the task, what do you need the robot to do? From there, look at what kind of grip you need, how it can integrate with your robot, and how much maintenance it’ll require.

A gripper is a type of end-effector. It’s one of the most common tools used to pick and place items, but “end-effector” is the broader term for anything attached to the end of a robot arm—including tools like welders, sensors, and suction cups.

The manipulator is the robotic arm itself, while the end-effector is what’s mounted at the end of that arm. It’s the hand of the robot; holding, lifting, welding, painting, you name it.

You might hear people call it a “robot hand” or a “robotic tool.” In more technical terms, it’s also referred to as the end-of-arm tooling (EOAT).

The actuator makes the robotic arm move, also referred to as “the muscle of the robot”. An end-effector, on the other hand, is the tool that does the task, such as picking up a box or tightening a screw.

Not sure which end-effector to choose?