Table of Contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Warehouse automation & AI: 6 myths debunked

Table of Contents

Automation and AI adoption have become one of the most – if not the most – important topics in the workplace. And when it comes to warehouse automation, adopting these technologies is becoming critical for maintaining efficient operations, especially with ongoing labor shortages and the pressure to stay competitive.

Yet, for many warehouse managers, the road to adopting these technologies is often clouded by misconceptions and fears.

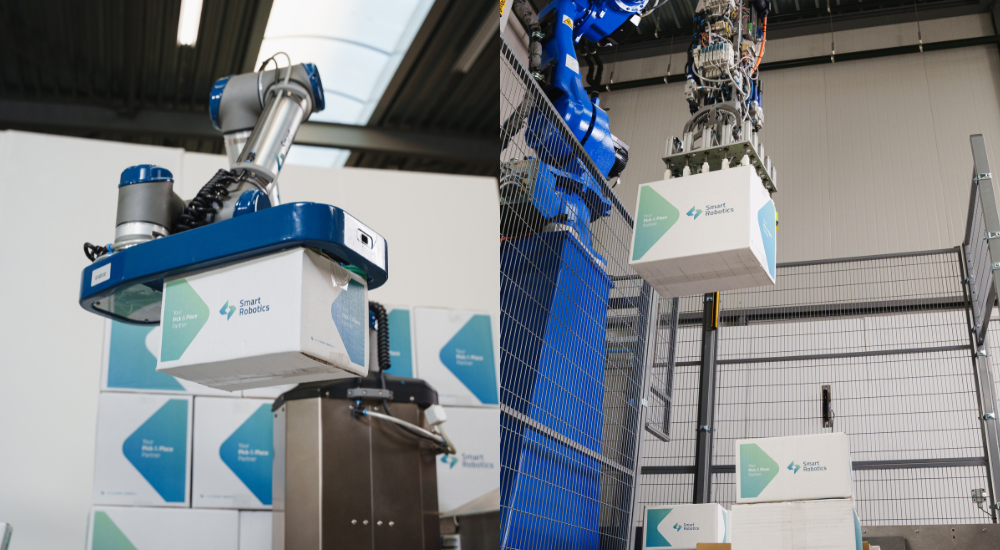

At Smart Robotics, we’ve seen firsthand how these myths can hold businesses back from becoming more efficient, more flexible, and more competitive. In this article, we’ll help separate fact from fiction.

1. “Automation is too expensive and only for big players.”

Myth: Adopting automation and AI in the warehouse comes with price tags that only big corporations can afford.

Reality: Automation isn’t just for the big corporations. In fact, around half of our customers are SMEs. Small to medium-sized companies like Vandemoortele, and even family-run businesses like Lebkuchnerei Woitinek, have successfully implemented our technologies to make their operations more efficient and future-proof.

Thanks to flexible purchasing options — including our “automation-as-a-service” model — many companies achieve ROI in less than two years, and sometimes within months, thanks to reduced labor costs, fewer errors, and faster throughput.

In short: Automation isn’t just for the big players; small and medium-sized companies are proving every day it’s affordable, fast to implement, and pays for itself quickly.

2. “Automation will replace human jobs.”

Myth: Once automation is adopted and AI is up and running, people will be out of work.

Reality: Automation doesn’t remove employees from a warehouse; it reallocates them to more fulfilling roles. Many operators we’ve spoken with say that repetitive, physically taxing tasks often have them contemplating leaving the job altogether.

When automation comes in to play, workers are freed to focus on more rewarding aspects of the job, such as quality control, system supervision, and customer service. This shift improves job satisfaction, reduces health risks, and naturally extends how long employees stay with an employer.

In short: Automation doesn’t replace people. It makes them do safer, more rewarding work they actually want to stay employed for.

3. “Automation makes operations inflexible.”

Myth: If I automate, my processes will be locked in and unable to adapt.

Reality: Today’s automation is built for agility. Even traditional palletizing systems can now handle changing product sizes and weights on the fly. Technologies like automated item picking adapt to new inventory all the time, without any pre-training.

In short: Today’s warehouse automation and AI are designed to be flexible, adjusting seamlessly to ongoing changes in inventory and demand. It’s as flexible as you need it to be.

4. “You must overhaul your operations to use AI.”

Myth: You need to stop or slow down operations to implement automation or AI.

Reality: You do not need to shut down or overhaul your warehouse to get started. You can start small. Many AI-driven solutions integrate with your existing setup and workflows, and can be installed while operations are still running.

In short: You don’t need a full-scale overhaul to adopt AI. Start small, keep moving, and build from there.

5. “Automation and AI are the same thing.”

Myth: Automation and AI are just two different words for the same type of technology.

Reality: While automation and AI can work together, they’re very different. Automation executes tasks with little or no human intervention, but it requires prior setup. AI, on the other hand, adds on-the-fly decision-making and adaptability to those tasks.

When combined, they create a warehouse that not only works faster, but works smarter.

In short: Automation gets the job done. AI makes it flexible and adaptable, fast. Together, they transform how your warehouse works.

6. “It’s too complex for my team.”

Myth: Advanced technology requires advanced in-house skills.

Reality: Many systems are as simple to operate as a smartphone. Modern automation is designed with the user in mind — intuitive interfaces, guided setup, and thorough operator training mean your team can get up and running quickly.

In short: You don’t need tech experts to run modern automation. If you have learnt how to use a smartphone, you can learn how to operate automation machinery.

Common fears to address

Even after the myths are cleared, it’s natural to have concerns. Here’s how you can address them and move forward with confidence:

Job security – Clear communication with employees helps avoid job insecurity and low morale. Be transparent about what’s happening, how roles will change, and what the timelines look like.

AI mistakes – To see if automation will work in your specific environment, many businesses feel more confident starting with a pilot project before full deployment.

Cybersecurity – When talking to vendors, ask about their cybersecurity protocols so you know exactly how your data and systems will be protected.

Workflow disruptions – Our team comes straight from the logistics and warehouse sector, so we understand how damaging disruptions can be. At Smart Robotics, we work with you to create an implementation plan that keeps disruptions minimal to non-existent, so your business keeps moving while we apply automation.

Resistance to change – When implementing automation or AI, it’s smart to involve the teams early. Celebrate wins together. Working towards something great as one team can make change feel more exciting and less intimidating.

Bottom line

Automation and AI are not here to replace human work. They’re here to take away the boring, repetitive tasks so people can focus on more value-driven roles.

The warehouses of the future will be hybrid environments where people and technology work together, not against each other. The sooner we embrace that reality, the sooner we can unlock simpler, smarter, and more productive operations.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Frequently Asked Questions

No. Many SMEs successfully implement automation using flexible purchasing models like “automation-as-a-service.” ROI can often be achieved in less than two years, sometimes in just months.

No. Automation takes repetitive, physically demanding tasks off employees’ hands and replaces them with more rewarding work like quality control and system supervision.

Not at all. Modern systems, from palletizing to automated picking, are built for agility and adapt to changing product sizes, weights, and SKUs without lengthy retraining.

No. Many AI-driven solutions can be integrated into existing setups while operations continue. You can start small and scale over time.

Concerns include job security, AI errors, cybersecurity risks, workflow disruptions, and resistance to change. All of these fears can be addressed with clear communication, pilot projects, robust security protocols, minimal-disruption implementation plans, and early team involvement.

Ready to see what’s possible with warehouse automation?