Table of contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Cobot vs. robot palletizer: which one is right for your business?

Table of contents

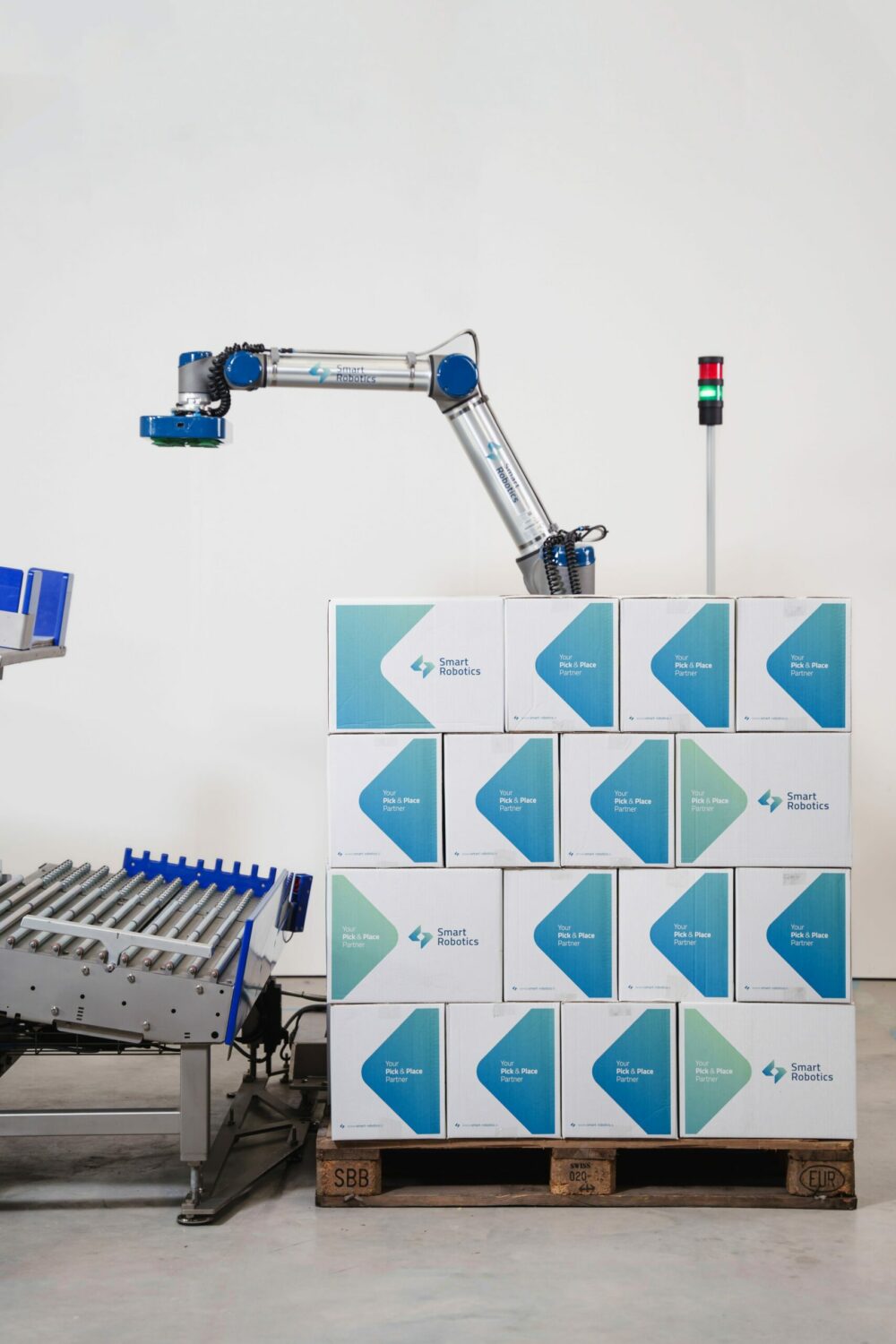

Unsurprisingly, the adoption of automation in various industries is on the rise. Robots and cobots are increasingly utilized for processes like palletizing—tasks that involve repetitive actions and are ideal for automation. However, choosing between a robot and a cobot palletizer requires careful consideration. At first glance, they appear similar: both employ robotic arms with grippers to stack boxes in specific patterns on pallets, can operate 24/7, and enhance productivity and efficiency. Nonetheless, key differences exist between the two.

What is a cobot palletizer?

A cobot, or collaborative robot, is designed to work alongside humans, enhancing workplace safety and efficiency. Equipped with advanced safety sensors, cobots eliminate the need for additional protective measures like fencing. To ensure safe collaboration, cobot palletizers have limitations on speed and power, typically handling products weighing up to 20 kg.

In the context of palletizing, cobots allow employees to work in close proximity—removing full pallets, placing empty ones—without halting operations. This continuous operation is advantageous for businesses relying on uninterrupted workflows.

Additionally, cobot palletizers are highly flexible, making them suitable for end-of-line processes with diverse products. They can be quickly installed and easily reconfigured to accommodate different products and stacking patterns. Their compact design enables seamless integration into existing production lines without significant modifications.

What is a robot palletizer?

Robot palletizers are designed for high-speed operations and handling heavier products. These industrial robotic arms are commonly used in large-scale manufacturing sectors, such as the automotive industry.

Due to their speed and power, strict safety measures are necessary, often involving enclosures to prevent human interaction during operation. If an employee needs to enter the workspace, the robot must come to a complete stop to ensure safety.

Unlike cobots, robot palletizers are large, fixed installations with a significant footprint. They are optimized for high-volume, high-speed production, executing specific repetitive tasks with precision. However, their lack of flexibility makes them less suitable for end-of-line processes that require frequent adjustments for varying product types.

Cobot vs. robot palletizer: which one should you choose?

There is no definitive answer to whether a cobot or robot palletizer is more suitable; the choice depends on factors such as speed requirements, product weight, and variety. If your production line involves a diverse range of products and requires adaptability, a cobot palletizer is likely the better option. Conversely, for high-speed, heavy-duty palletizing tasks, a robot palletizer may be more appropriate.

Conclusion

Before making a decision, it’s crucial to define your specifications and assess your operational needs. If you’re interested in learning more about the benefits of a cobot or robot palletizer, consider contacting us to speak to one of our palletizing experts.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.