Why choose the Smart Depalletizer?

The Smart Depalletizer tackles common challenges in logistics and warehousing:

- Growing labor shortages

- Increasing consumer demand and variety

- Boost efficiency whilst decreasing operation costs

- Ensure compliance with health and safety standards

- Reduce employee turnover from dull, repetitive and physically straining tasks

- Unloads a diverse range of product sizes, mixed SKUs and packaging types without the need for SKU teaching

- Integrates seamlessly with your hardware (cobots and industrial robots) for faster throughput or heavier loads

- Unloads products from any container type including cages, containers and pallets

3PL

Retail

E-commerce

Gen Merch

Food

Top 5 Things to Consider When Automating

Your incoming warehouse volumes & desired throughput rate

Size, weight, and variety of items on the pallets

Warehouse layout and available footprint

How the system will integrate with existing workflows

Setting the right KPI’s for your process

Top Features

High Throughput

Process up to 1000 products/hour with speed and precision

AI Powered Precision

AI determines the optimal cup configuration. Each pick is precise without the need for SKU teaching.

Seamless Integration

Easily integrates with your existing workflows and adapts to different warehouse layouts

Gentle Item Handling

Minimizes the risk of product damage with intelligent handling

Benefits of Automated Depalletizing

The benefits of depalletizing solutions include increased efficiency, improved health and safety, and reduced labor costs. These solutions are fully customizable to meet the unique requirements of various industries and businesses.

HIGH LEVEL OF

Performance &

Reliability

- Precise handling of a large variety of product sizes, shapes and packaging types

- Delivers error-free picks, minimizing downtime

- Continuous operation and achieves a consistent flow of goods

- Increases throughput and accuracy for a reliable performance

HIGH LEVEL OF

Learning &

Adaptability

- Utilizes AI-driven software to improving efficiency

- Handles all products without SKU-specific teaching

- Provides flexibility to adapt to growing operational needs

HIGH LEVEL OF

Flexibility &

Scalability

- Fully compatible with cobots and industrial robots

- Customized solutions for higher throughput or heavier loads

- Designed for seamless integration into existing workflows

- Scalable solutions to integrate additional robotic systems

HIGH LEVEL OF

Service &

ROI

- We offer picking automation as a service, including hardware, software and ongoing support

- An Online Helpdesk and dedicated customer service team available, maximizing your ROI

AI-Powered Depalletizing

Watch video

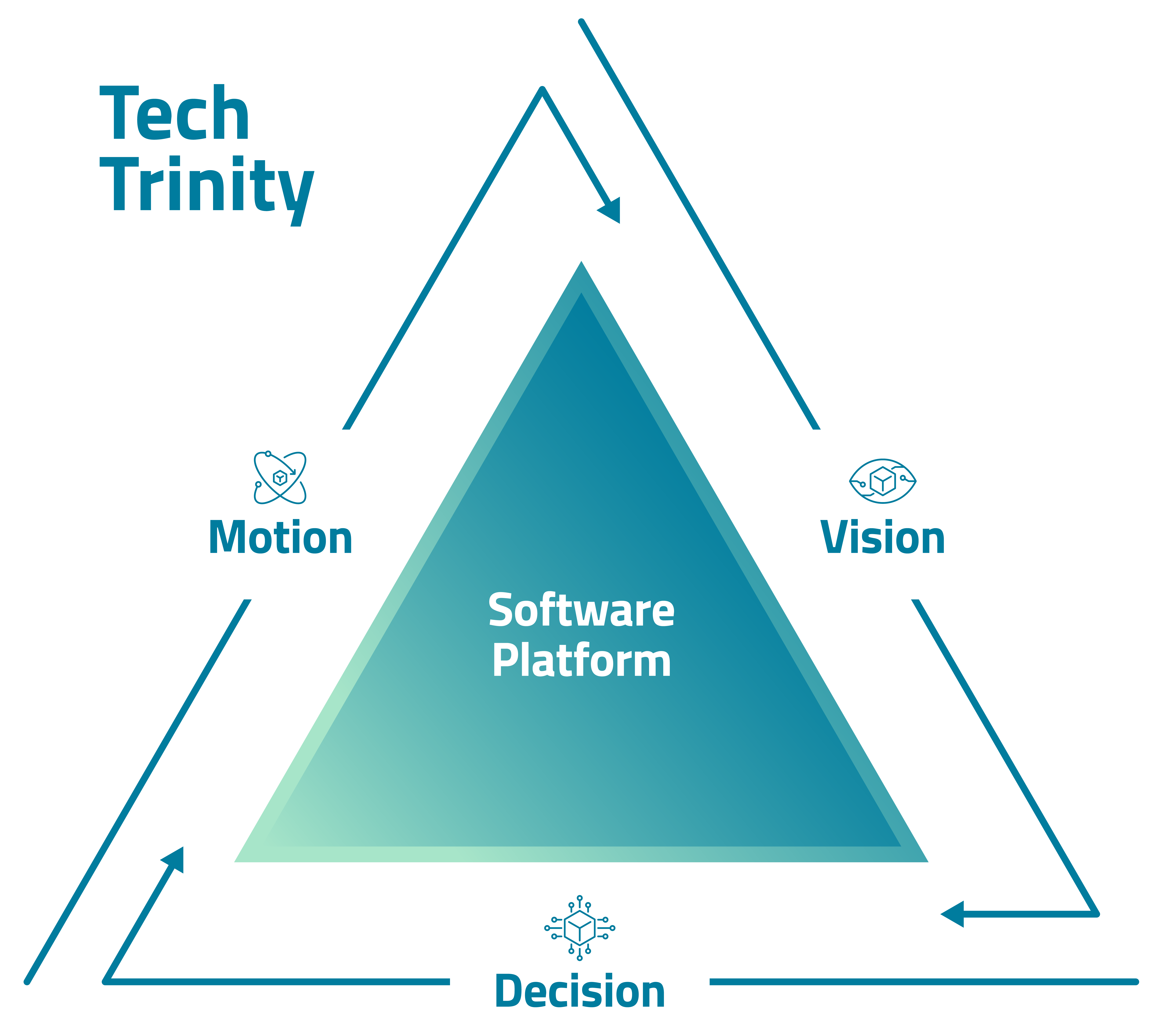

AI Vision Motion and Decision

Through our technology trinity the combination of advanced AI Vision, Motion, and Decision-making algorithms, our smart depalletizing solutions easily adapt to dynamic workflows and consistently deliver under unpredictable conditions. They adjust to changing workflows, maintaining high accuracy and optimizing container filling for different products.

Download the free whitepaper

This whitepaper provides a guide to the complexities of warehouse automation implementation, offering clear, actionable insights for businesses considering this strategic move. Download to unlock the full potential of automation in your warehouse operations.

Test your products at our Innovation CenterBook a Demo

FAQ

Smart Depalletizer

The Smart Depalletizer is a reliable robotic system designed to unload or depalletize a wide range of products (single and mixed SKUs) from a pallet (and other containers). This system can handle diverse packaging types and is designed to integrate seamlessly into your existing logistics operation, automating manual unloading tasks efficiently.

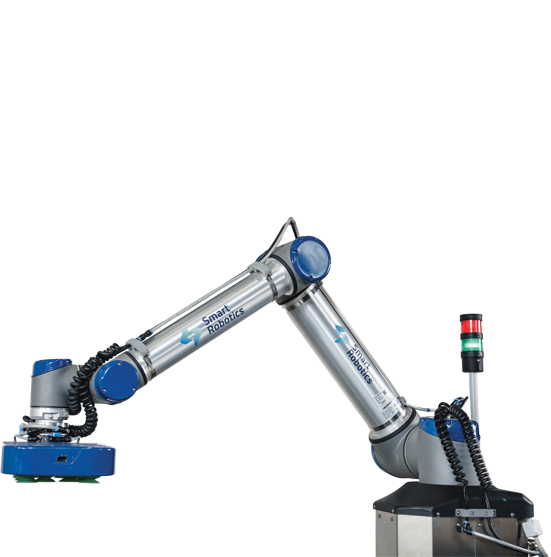

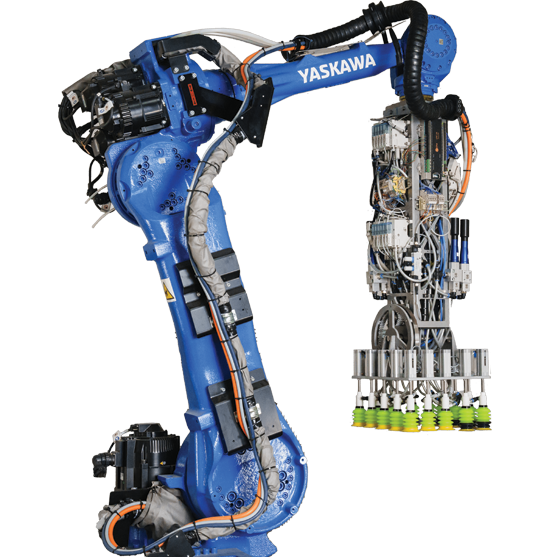

The Smart Depalletizer comes with flexible hardware solutions, including both cobots (collaborative robots) and industrial robots, to meet a variety of operational requirements. Alongside the robotic arms, we provide a range of hardware such as grippers and suction tools tailored for handling different product types, conveyors for seamless material flow, and additional safety devices to ensure secure and efficient operation. Partnering with trusted suppliers, we deliver a fully integrated depalletizing system capable of handling everything from lightweight parcels to heavy and diverse items.

Depalletizing solutions are typically installed at the inbound area of the warehouse workflow. They are used to unload and process incoming goods from pallets, preparing them for sorting, storage, or further automation steps such as picking and packing. This placement streamlines the inbound logistics process and enhances overall efficiency.

Have another question? Contact us