Table of Contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Understanding the differences between palletizing and depalletizing

Table of Contents

At first glance, it seems like one robot and one software configuration should be able to palletize and depalletize products from a pallet.

But is that really the case? Can you deploy a single robot in your facility to manage both stacking and unstacking products, or do these two tasks require different solutions?

Considering the differences in placement within a facility and the unique requirements of each task, we can come to a better understanding of these two automation roles.

In this article, you’ll gain a clearer view of what’s required for both procedures, and which approach makes the most sense for your logistics.

Let’s dive in, starting with…

The definition of palletizing

Palletizing is the process of systematically stacking packaged goods (such as taped boxes or crates) on a pallet, ready to be shipped.

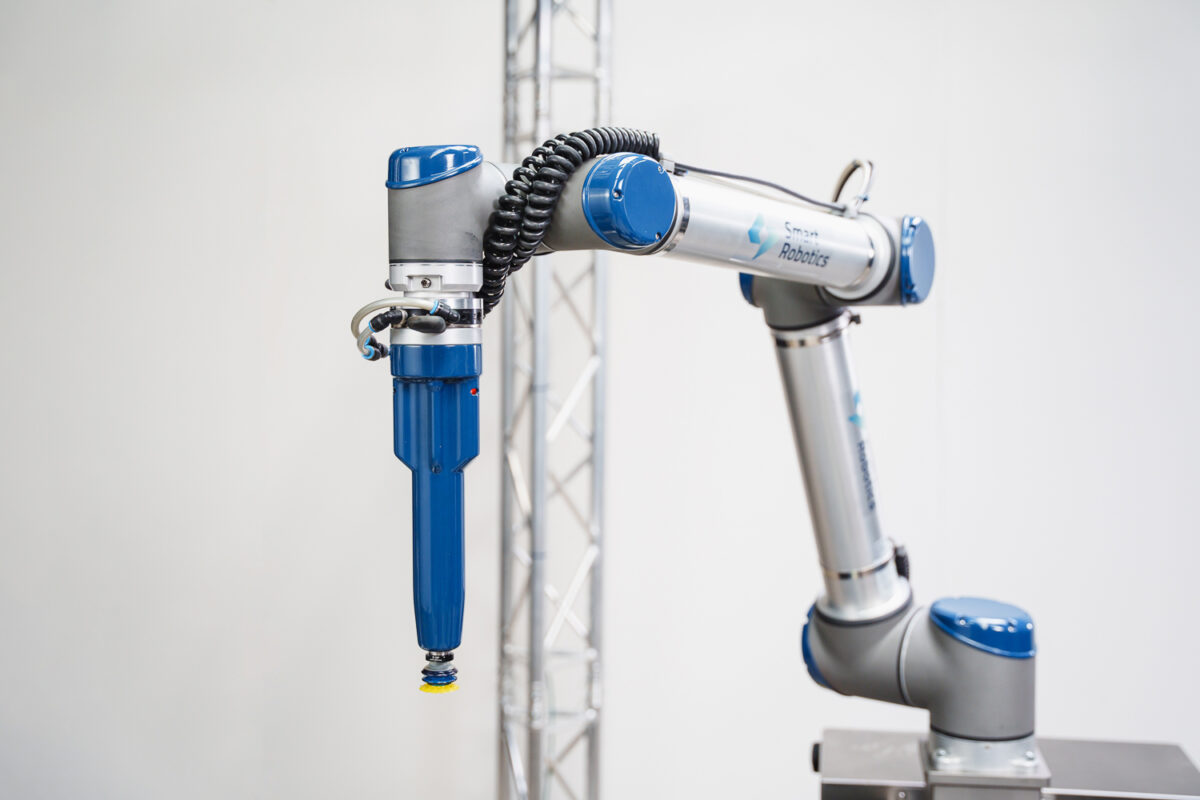

Robotic palletizing takes it a step further by using robotics to handle the task, either stacking products layer by layer or unit by unit.

In some facilities, palletizing is still done manually. An employee lifts packaged products from the end of the production line and stacks them onto an empty pallet. This is physically demanding work, and it’s no surprise that employee turnover is usually high in those environments.

However, as automation continues to rise and logistics companies face ongoing labor shortages, robotic palletizing is becoming more prominent. It’s especially valuable for companies with high throughput and a need to get products out the door fast.

The definition of depalletizing

Depalletizing is exactly the opposite of palletizing; it’s the process of unloading packaged goods from a pallet. This usually happens when a freight truck arrives full of pallets that need to be emptied.

From there, the products can be placed onto a conveyor belt at the start of the production or manufacturing line or onto another pallet (a process known as repalletizing).

As you can imagine, this task can be very physically demanding on the employees, constantly lifting and placing products onto conveyor belts for hours on end each day.

The similarities between palletizing and depalletizing

Yes, there are some similarities between palletizing and depalletizing, and it’s worth highlighting these before jumping into the differences:

- Both applications can be done with the same robot. One of our palletizers, the Smart Mixed Case Palletizer, can easily handle both palletizing and depalletizing tasks.

- They are both classified as pick-and-place jobs: very repetitive and monotonous work no one wants to do.

- They’re often a huge hurdle to production and logistics facilities, mainly due to inefficiencies caused if these tasks are done manually.

- The installation procedure for both applications takes around the same time and follows the same integration procedure. The only difference is that a depalletizer needs a top-mounted camera for vision, which adds a bit more time compared to a palletizer.

Key differences between palletizing and depalletizing

Now that we’ve discussed the similarities between palletizing and depalletizing, let’s take a look at the differences:

Depalletizing challenges

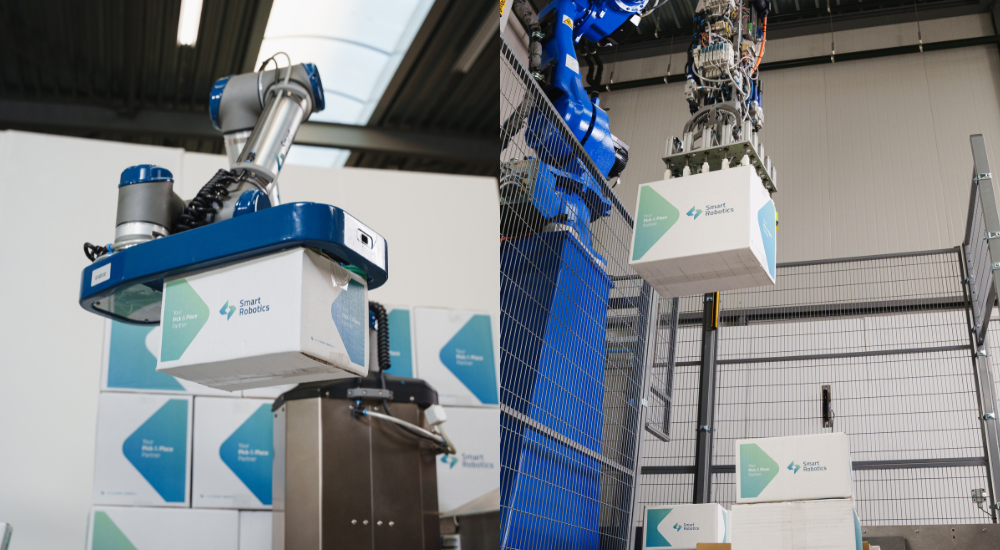

When a robot stacks a pallet with identical boxes, it knows exactly where to place them thanks to predetermined stacking pattern technology. This means the machine, even without a vision system, can pick up the packaged product and know exactly where to place it.

There is still some thinking involved, like determining the ideal spot to place the product. But for the most part, for a single SKU palletizing solution, it’s all predetermined.

Mixed case palletizing usually does not use vision to place products on a pallet but relies on intelligent software to figure out the best stacking pattern. Vision can be applied for real-time validation or adjustments, but it’s not an absolute requirement.

However, depalletizing is a bit more complicated because of…

Items moving during transit

During transit from one facility to another, products can shift and move—especially if they weren’t secured well enough with shrink wrap. This can cause problems for a visionless robot, which relies on picking up goods from an exact position. If the products have moved even slightly, the robot will likely encounter an error and won’t be able to do its job properly.

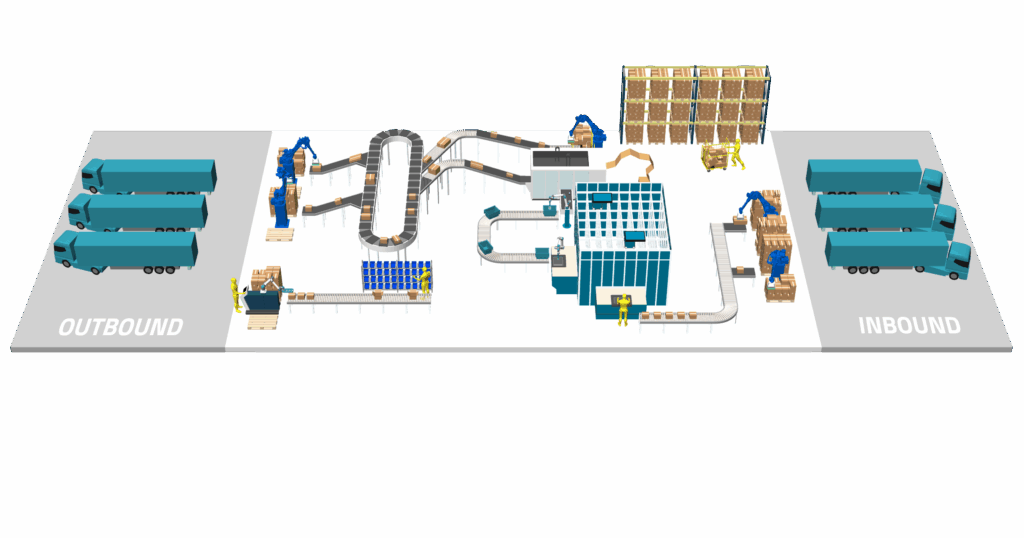

Different locations and processes in your facility

Commonly, palletizing and depalletizing processes happen in different areas of the facility. Palletizing happens at the end of the process, after packing cases, sealing, and taping, when the product is ready to be placed on a pallet and shipped.

On the other hand, depalletizing happens at the beginning of a facility’s process, in the inbound phase. Depending on the type of facility, this usually happens when packaged products arrive and need to be unpacked and sorted to start their journey through the production line.

Sometimes, two robots, one handling the palletizing process and one handing the depalletizing process, can work side by side in the same location in the facility.

But that depends on the type of solution a facility needs. You can contact us today for a free, customized solution for your business.

How to decide if you need a palletizing or depalletizing solution

One of the most common questions we get is this: should I start automating with a robotic palletizer or depalletizer?

The answer depends entirely on your facility’s needs.

Start by asking yourself these questions: –

- Where do bottlenecks usually occur in my process? At the start of my line or at the end of it?

- What is my throughput requirement; Do I need fast stacking or fast unstacking?

- Am I dealing with labor shortages in one specific area?

- Do I need the same robot to do both tasks?

Take a look at our palletizing and depalletizing solution pages. If you still have questions or would like more information about either solution, feel free to contact our experts.

In Short

Palletizing and depalletizing both involve moving packaged goods on and off pallets. They share similarities in being repetitive, physically demanding tasks that can be automated.

However, the main differences come down to where they fit in your process and what the machine needs to do to execute the application successfully.

Robotic depalletizing usually requires vision in order to do it right, while automated palletizing typically doesn’t.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

FAQs

Both palletizing and depalletizing processes have some things in common:

- Are repetitive “pick-and-place” tasks that are monotonous and physically demanding for workers

- Can be performed using the same robotic systems

- Follow similar installation and integration workflows

The primary difference in setup is that depalletizing often requires a top-mounted camera for vision, increasing complexity over palletizing

Yes—in many cases, the same robotic platform can perform both tasks. However, for depalletizing, additional vision systems (e.g., top-mounted cameras) may be needed to handle the variability and misaligned loads on incoming pallets.

Yes. Depalletizing typically deals with variability: cases may have shifted during transport, making predefined pickup points unreliable. Vision systems (like top-mounted cameras) help the robot locate items accurately.

Automate Your Production with our Palletizing & Depalletizing SolutionsGet Started Today