Table of contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

AutoStore and pick and place robots: the future of warehousing

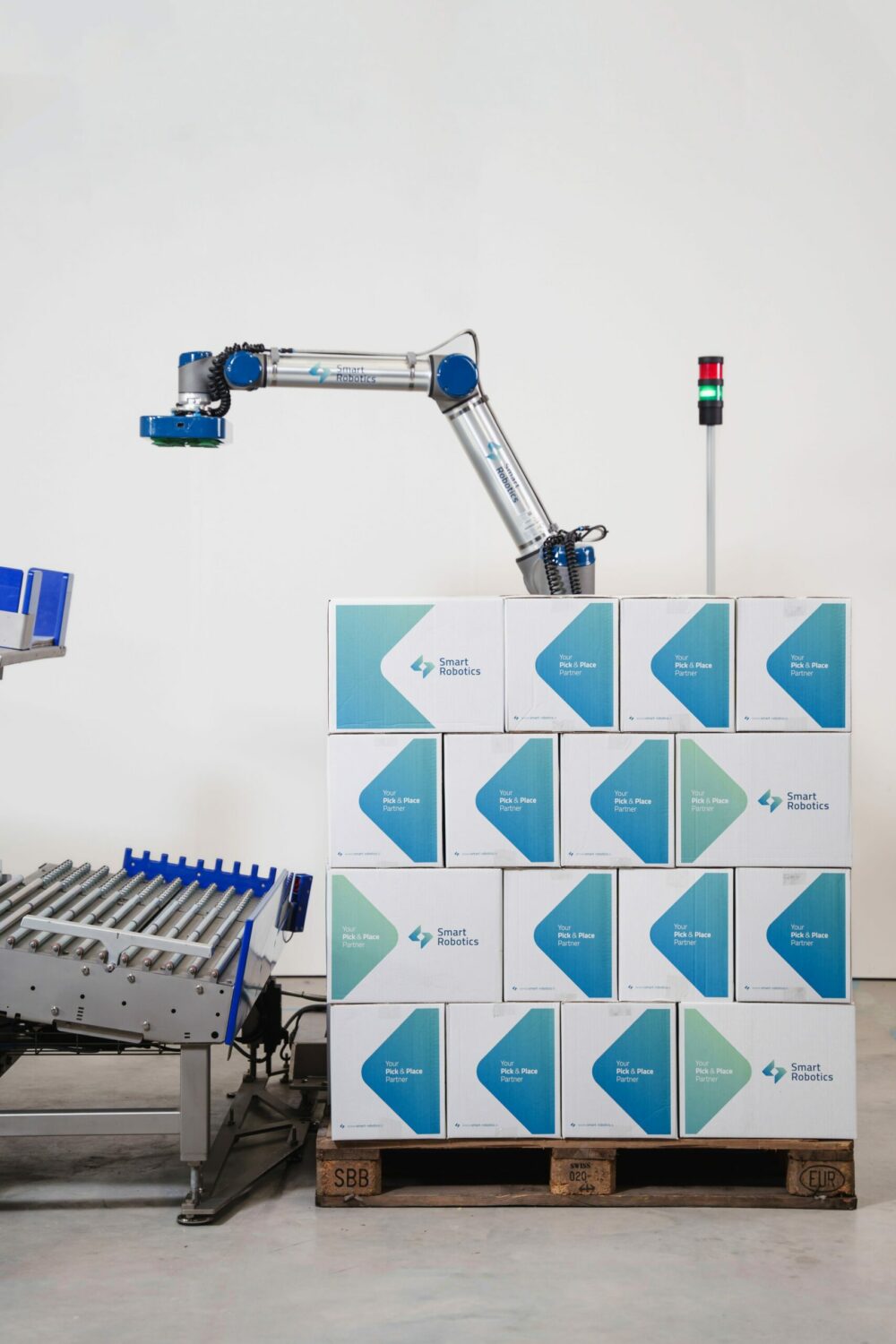

The world of e-commerce has exploded in recent years, and it’s not slowing down anytime soon. To keep up with growing consumer demand and labor shortages, many warehouses are turning to automation to make their fulfillment processes faster and more efficient. One of the best solutions out there is AutoStore, an advanced storage system that delivers goods right to a picking station. Traditionally, a person would pick the items, but now, pick & place robots are stepping in to do the job even better.

From people to robots: The future of AutoStore

Many warehouses already use goods-to-person systems like AutoStore to improve efficiency and save space. But what if we could take it a step further? By replacing manual picking with robots, we can boost speed, accuracy, and productivity—all while reducing the strain on human workers.

Why automating AutoStore makes sense:

1. Lower costs, higher efficiency

Adding pick & place robots to AutoStore means lower operational costs. With faster, more precise order fulfillment and fewer errors, businesses can save money while improving service. Plus, with less reliance on manual labor, companies can cut down on hiring and training costs.

2. Solving the labor shortage problem

Finding people to do repetitive warehouse work isn’t easy. High turnover and labor shortages make it even tougher. Pick & place robots help by taking over these tedious tasks, keeping fulfillment running smoothly without worrying about staffing shortages.

3. Happier Employees

Nobody enjoys repetitive, physically demanding work. The good news? Robots can handle the dull, exhausting tasks, freeing up employees to do more interesting and valuable work. Plus, fewer night shifts and less physical strain mean a better work environment overall.

4. Fewer Mistakes, More Accuracy

When humans pick items manually, mistakes happen. Robots, on the other hand, use smart vision and AI to identify, pick, and place items with incredible precision. This reduces errors, minimizes costly returns, and keeps customers happy.

5. 24/7 Productivity

Unlike human workers, robots don’t need breaks. They can work around the clock, making sure warehouses operate at full capacity even during peak seasons. Faster order processing means quicker deliveries and satisfied customers.

6. More Storage, Less Space Needed

With their compact design, pick & place robots don’t take up much space. Unlike traditional conveyor belts or large manual workstations, these robots maximize warehouse storage capacity, helping businesses get the most out of their facilities.

7. Ready for the Future

One of the biggest perks of pick & place robots is how easily they can scale. As your business grows, you can add more robots without disrupting operations. That means warehouses can expand effortlessly, staying efficient and competitive in the long run. By combining AutoStore and pick & place robots, businesses can create a fully automated, super-efficient fulfillment process. Faster order handling, fewer errors, and reduced labor costs make this a game-changer for modern warehouses.

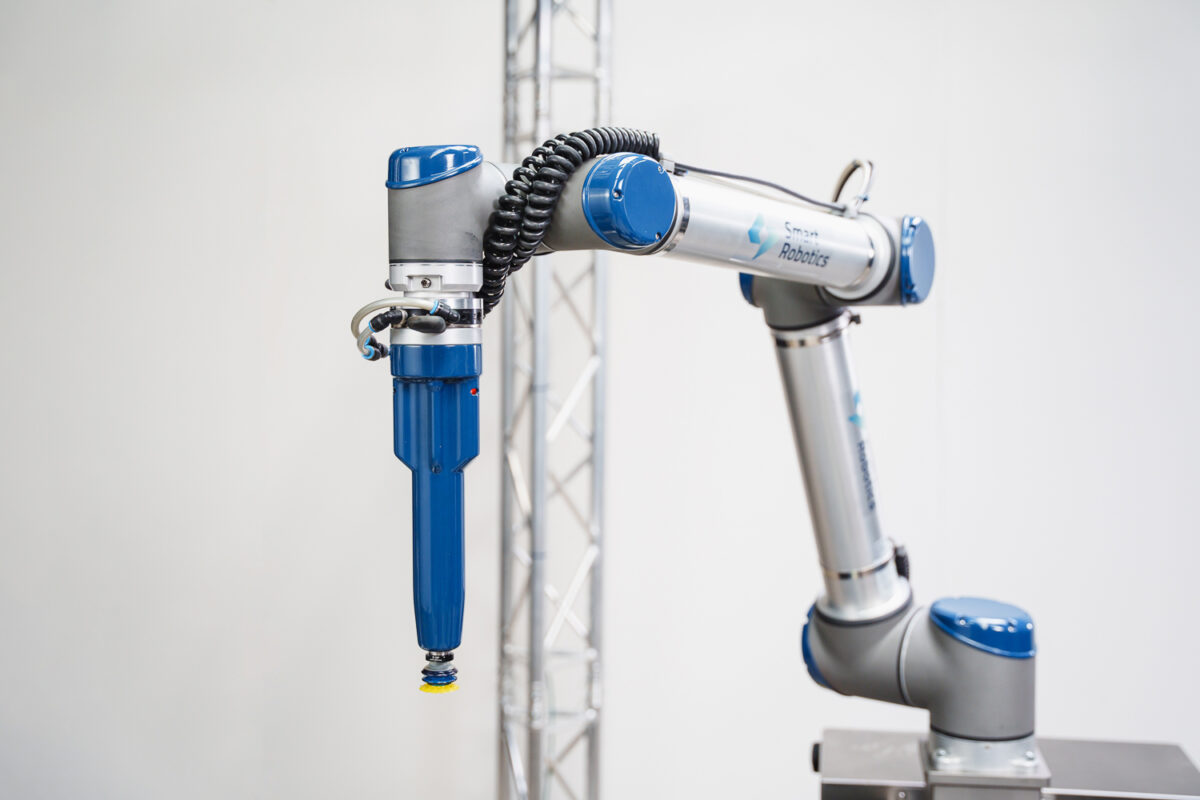

At Smart Robotics, we specialize in easy-to-integrate pick & place robots designed to enhance AutoStore systems.

Want to learn how this could work for you? Contact our experts today for a no-obligation consultation and see how automation can take your fulfillment operations to the next level.

Download our free white paper

Learn how to implement the ideal pick & place robot in your warehouse. Leave your contact details and receive a download link to our free white paper.