Implementing pick & place robots in your warehouse – step 3: design

Table of contents

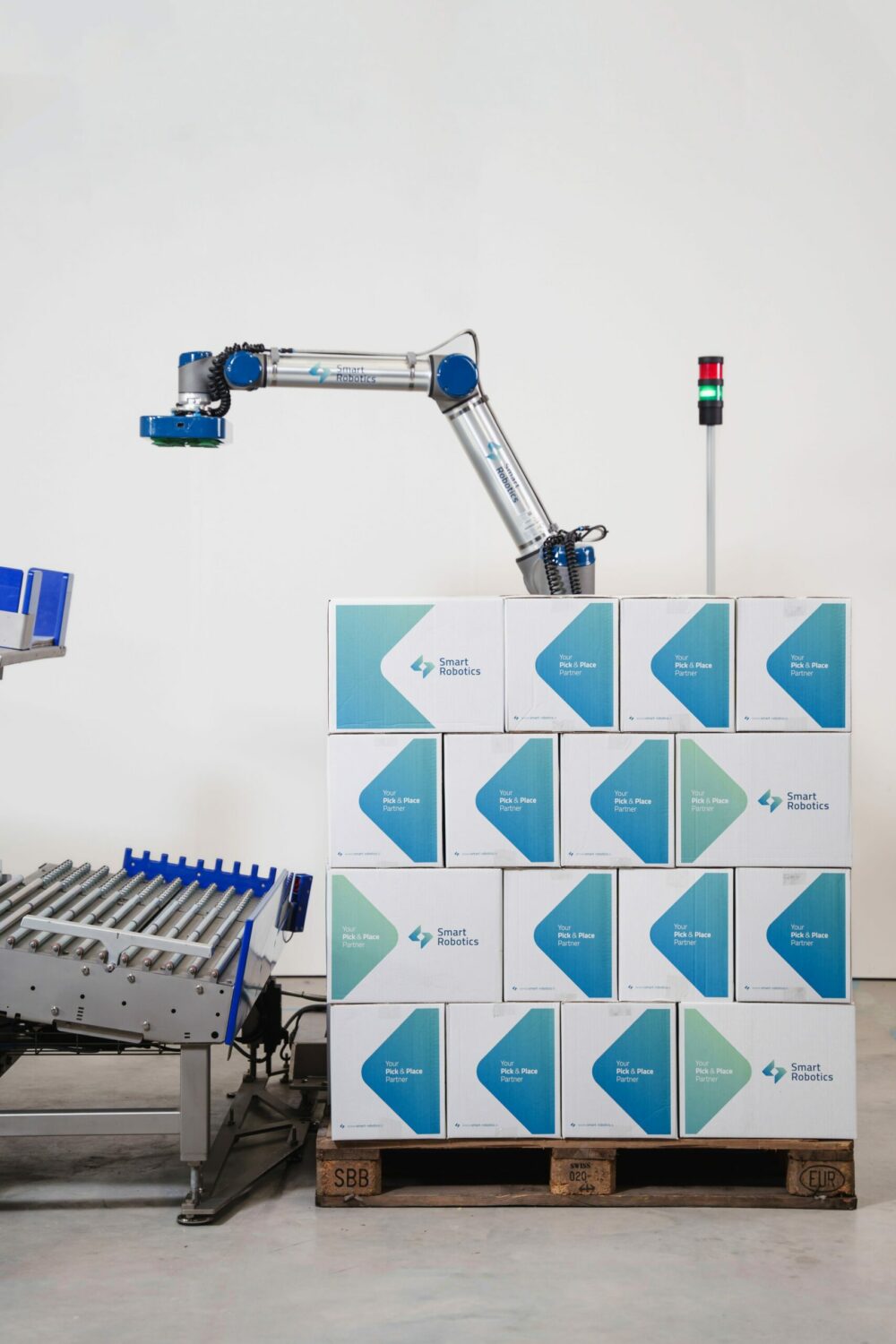

For many companies, implementing pick and place robots in their warehouse is very new. Good preparation is needed. To come to the best decision, there are four phases to go through: exploration, proof of concept, design and implementation. In this blog series we will discuss what steps to take in each phase to ensure the successful implementation of pick and place robots in your warehouse. Now that you have passed the exploration phase and proof-of-concept phase, this third blog will help you designing a robot implementation plan. There are several subjects that should be included in the design of this plan:

Functional pick & place robot requirements

What parts of your exploration phase are still unclear? What would you like to clear up? Especially think about:

- Task variation: What tasks will the robot execute exactly? For instance, alongside the picking and placing of products, does the robot need to scan product barcodes too? If so, are the barcodes at the correct position of the products? Or will barcodes be scanned by a scanner in a different part of process?

- Speed & pickability: In the proof of concept phase, you have learned what is realistic. Subsequently, you should find a match between your production requirements and what the pick and place robot can handle. If 2400 items have to be picked and placed per hour, and the robot can handle 800, then you would need at least 3 robots to meet your requirements. You might want to add redundant capacity, depending on the expected downtime in your process.

- Product supply: How will the products be supplied to the pick and place robot? This is crucial to consider, as you want the robot to run continuously. A solution could be to whitelist and blacklist products; making lists of products the robot can and cannot handle. Products that are on the ‘blacklist’ can then be sent to a picking station with a human operator.

- Operator support: Does the robot need support from an operator? And how often would it be required? These are essential questions that can help determine where to position the pick and place robot in your warehouse and how easily accessible it should be. This will help you with your floorplan design.

Interfacing your Pick & Place robot

Besides the functional requirements, it is principal to thoroughly think of the interfacing of the robot with surrounding hardware as well as your warehouse control system (WCS). To ensure smooth operation, the robot should be able to communicate with your WCS. In this step, it is key to:

- Systems: make a list of all the systems the robot has to interface with.

- Specifications: decide on the specifications of the interfacing, in close cooperation with your supplier. What data should the robot receive and what should the robot send? At what rate is this data required. What control possibilities are required from the control room (start/stop, resume, etc.)

Non-functional requirements of your pick & place robot

Non-functional requirements are all the additional elements the robot might or will need for a seamless integration in your warehouse. Examine requirements such as:

- Internet connection: does the robot need to be connected to the internet – e.g. for monitoring, remote error handling and update purposes? If so, how do you create a secure connection?

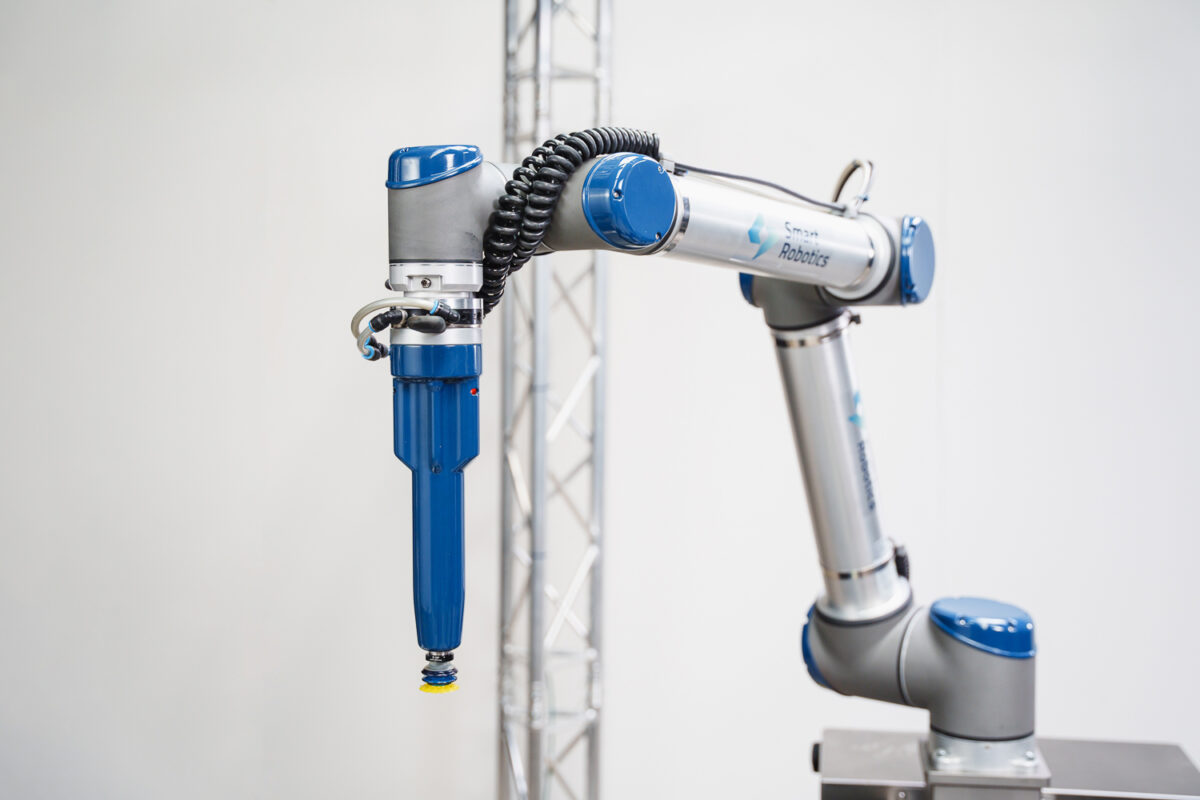

- Compressed air: is the compressed air supply available via a central system? Or do you need to generate it locally?

- Electricity: cobot solution can easily be plugged into your regular electricity grid as it has a very low electricity consumption. However, if you are implementing industrial robots, they will need a separate power group as they consume a higher amount of electricity.

Floorplan for your pick & place robot

With the information you have gathered on functional requirements, interfacing and non-functional requirements, you can design a floorplan determining where to place the pick and place robot(s) in your new or existing warehouse. When drawing this floorplan, it is essential to think about how the robot is integrated with the surrounding systems. Next to that, the accessibility depending on operator support is an important requirement to find the best layout.

Robot service plan

Furthermore, think about how you would like to address service of the pick and place robot. As with any machine, it is likely that at some point issues might occur or maintenance is needed. The service you need depends on how critical the robot solution will be in your warehouse fulfillment process. Some questions to ask yourself when thinking about service are:

- What problems can we solve internally and what problems will we need a service team for?

- If service by the supplier is needed, how quick should the response time of service be?

- Can the suppliers’ service team access the robot remotely to solve issues?

- Do we want spare parts in stock on site for quick replacement?

- Do we want a service contract or pay per service request?

Pick & place safety

Another aspect to consider when designing your robot implementation plan is to inspect safety. How do you ensure the pick and place robot meets the safety requirements of your warehouse? Together with your supplier, you can determine possible risks and how to solve them.

Note that industrial robot solutions require a lot of safety measures by default, including a large safety cage around the solution. This has a severe impact on your floorspace. Cobots, on the other hand, do not need a safety fence and are easier to implement within an existing line. Nevertheless, cobots may require supplementary safety measures as well. For example, besides the standard safety features of a cobot that already ensure safe cooperation with people, you can add a safety scanner that ensures the robot moves slower while an operator is in close proximity.

Engage your operators

In addition, also consider your operators. Automating manual tasks with a pick and place robot will change the jobs of your operators and warehouse employees significantly. Acceptance is key, as they will have to work together with a robot or cobot. Involve your employees in the process of automation and ensure they feel heard.

Roll-out pan for your pick & place robots

After analyzing all key aspects of implementing a robot in your warehouse, it is time to design the roll-out plan. Are you planning to implement multiple pick and place robots in your warehouse or even in multiple warehouses? It could be wise to start small and spread the roll-out over several phases. Even after extensive testing in the proof of concept phase, risks still exist. If you start small, any issues that occur will have less impact and there is still time and opportunity to improve the solution before further roll-out.

After the design phase, you will finally implement and optimize your pick & place robots. This phase will be discussed in the upcoming blog as part of the ‘implementing robots in your warehouse’ series. Stay tuned!

Download our free white paper

Learn how to implement the ideal pick & place robot in your warehouse. Leave your contact details and receive a download link to our free white paper.