Table of contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

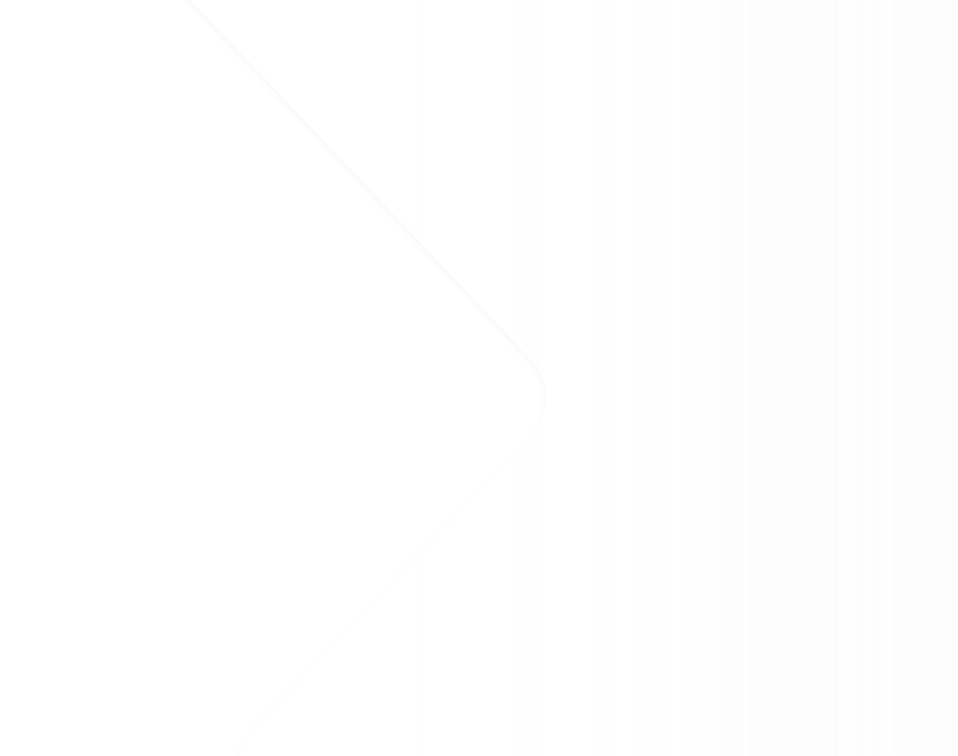

Implementing robots in your warehouse – step 1: exploration

Table of contents

For many companies, implementing pick and place robots in their warehouse is very new. Good preparation is needed. To come to the best decision, there are four phases to go through: exploration, proof of concept, design and implementation. In this blog series we will discuss what steps to take in each phase to ensure the successful implementation of pick and place robots in your warehouse. This first blog will focus on the questions you should ask yourself in the exploration phase.

Why implement pick and place robots in your warehouse?

Nowadays, many warehouse managers are exploring robotics. There are various reasons why implementing robots is important:

- High customer demand; output needs to increase whilst labor shortages are growing

- Labor costs rise whilst operating costs need to be reduced to remain competitive

- Health and safety rules for manual labor are getting stricter; it becomes harder to keep the work in your warehouse attractive to new employees.

These challenges ask for rigorous adjustments in your warehouse. Implementing pick and place robots can be an important part of the solution, but where do you start?

How do I start implementing robots in my warehouse?

The first step is to map out the manual pick and place processes in your operation, as that is where you can realize the greatest cost savings. Try to break these manual processes down to all tasks an operator has to execute. The most repetitive tasks are the ones that are easiest to automate with a pick and place robot. The more repetitive and monotonous the task, the better suitable for a robot.

What part of my fulfillment process is best suitable for robots?

Now that you know what manual tasks are most repetitive, look at the following topics to discover how suitable these processes are for robotics:

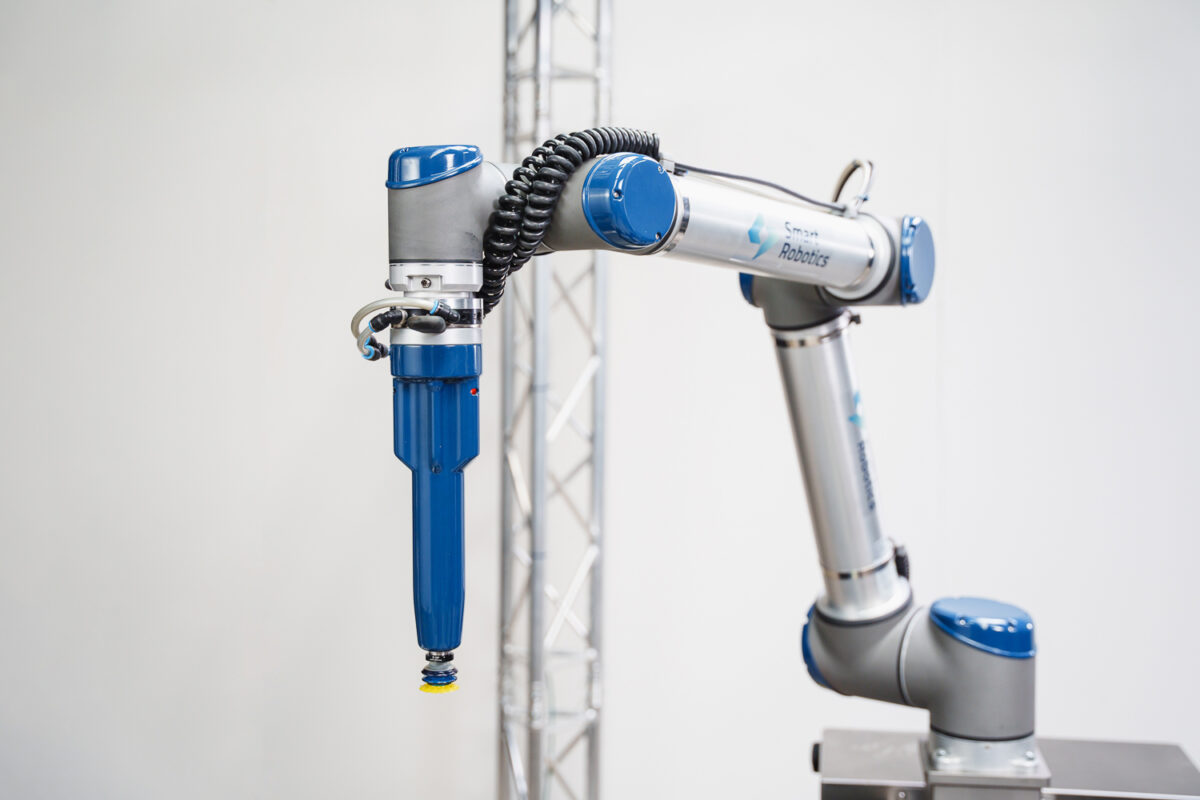

- Task variation: The smaller the task variation, the easier it is to automate. Robots are most suitable to execute one specific task, such as palletizing or item picking and placing.

- Product variation: The smaller the product variation, the easier it is to automate. Note that robots are becoming better and better at handling product variation. Hardware and software are continuously improving.

- Capacity: Robots can usually handle a capacity of 300 to 1000 picks per hour, depending on the task.

- Reach: A robot arm including gripper can typically handle a reach of 2×2 meters.

- ROI: looking at a productivity of 10 hours per day, robots typically have an ROI of 3 years. For cobots, or collaborative robots, the ROI is about 1-2 years.

How to adjust my fulfillment process for optimal robot functionality?

A pitfall is trying to replace an operator with a robot 1-on-1. After all, humans and robots have different skills. To ensure optimal robot functionality, changes in your fulfillment process may be necessary. Some examples:

- Tote filling rate: reaching the highest tote filling rate by rearranging products is a task more suitable for a human operator. A possible solution is to have robots fill the totes but have the order completion executed by a human operator.

- Batching: some products are harder for a robot to grasp. It can be useful to ‘blacklist’ products that the robot cannot or should not handle. This way, you can automatically create batches that the robot can pick without problems. The more difficult products can then be sent to human operators.

- 24/7 operation: manual processes are usually not optimized for 24/7 operation as night shifts lead to high costs. However, a robot can easily operate 24/7. Improve your business case by ensuring the robot can operate off peak.

The general rule of thumb is giving the highly repetitive tasks to a robot, and the more varying and creative tasks to an operator.

How do I build a business case for implementing robots?

During the exploration phase, it is important to gain insight into the costs of robots versus the costs of manual labor. The following formulas can help you make an estimation of the difference. Though, for a substantiated estimate, it is wise to enlist the help of a robot integrator.

- Operator effort per process step X hourly rate = cost per pick>

With a MTM (Methods Time Measurement) analysis the operator effort per process step can be determined. Multiply the operator’s effort with the hourly rate. The result shows the cost per pick. Beware that operator costs should also include overhead costs such as lunchtime, absenteeism, sick leave etc. - Robot costs / capacity = cost per pick

To calculate the costs of a robot, a cycle time analysis is needed in which you determine the expected capacity (typically between 500 – 1000 picks per hour). Again, overhead costs should be included, such as maintenance and malfunctions. By dividing the costs of the robot by the capacity, the cost per pick can be determined.

What about my operators?

Besides building a solid business case, it is important to consider another thing, your operators. Automating manual tasks with robotics will change the jobs of your operators and warehouse employees significantly. Acceptance is key, as they will have to work together with a robot or cobot. It is important to involve your employees in the process of automation and ensure they feel heard.

Now that you have explored in what part of your warehouse pick and place robots can be implemented and have built a solid business case, it is time to go on to the next phases: proof of concept, design and implementation. These phases will be discussed in the upcoming blogs in the series ‘implementing robots in your warehouse’.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Download our free white paper

Learn how to implement the ideal pick & place robot in your warehouse. Leave your contact details and receive a download link to our free white paper.