Table of contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Implementing pick & place robots in your warehouse – step 4: implementation

Table of contents

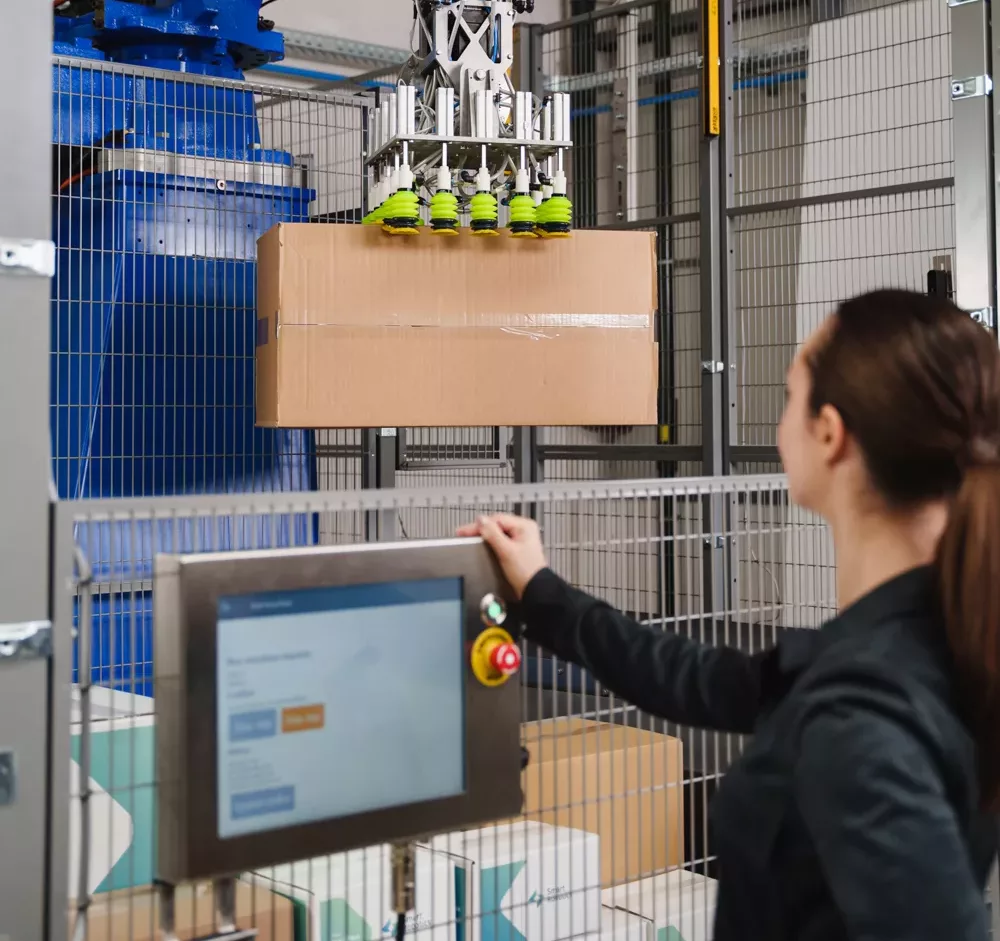

For many companies, implementing pick and place robots in their warehouse is very new. Good preparation is needed. To come to the best decision, there are four phases to go through: exploration, proof of concept, design and implementation. In this blog series we will discuss what steps to take in each phase to ensure the successful implementation of pick and place robots in your warehouse. Now that you have passed the exploration phase, proof-of-concept phase and design phase, this final blog will help you implement and optimize your new pick and place robot.

Following the extensive research and preparations, the time has come for the actual implementation of your pick and place robot. The installation is the easy part of this phase. What comes after, however, is much more important. Once the pick and place robot is running in your operation, you will learn:

- How stable is the robot in the long run?

- Where can I further optimize my process?

- Do my operators need additional training?

Right away, you should strive for improving the performance of the robot. In an ideal world, your pick and place robot operates completely autonomous at a 100% availability rate. That is a challenge, but it does not mean you should not aim for it. There are always steps that can be executed to improve the performance of your pick and place robot.

Data monitoring to improve robot performance

It is fundamental to continuously monitor the performance of your pick and place robot, based on the KPI’s you have determined. This data can then be analyzed to see where improvements can be made, both in the process as well as at the robot. Let us look at some examples of process optimization and robot optimization.

- The robot has to wait for picking totes to be supplied: This affects the items per hour the robot can pick and place. Investigate your goods to robot process and see what causes this delay.

- The pick and place robot has to wait for an empty space on the sorter belt to place a product: Can improvements be made in the sorter process to enable the robot to continue its operation?

- The robot receives products that are packed in an open plastic bag, causing the product to fall out during the pick and place movement totes to be supplied: Can the packaging of the product be changed? If not – put the product on a blacklist and send it to a picking station with a human operator.

- Operators do not use the robot correctly: For instance, an operator taking a break blocks the robot sensor intentionally so the robot thinks it cannot place a product, instead of pausing the robot correctly via the user interface. This can clutter your robot data as it is shown as an error or waiting time resulting in ‘lower’ productivity of the robot.

- The robot accidentally picks two products at the same time: this problem may arise when two similar items lie very closely together in the pick tote, resulting in the robot’s vision thinking it is one and the same item. The supplier can solve this issue by improving the deep learning model of the robot.

- A product is dropped accidentally and blocks a sensor: A solution could be to build a slide around the sensor so that a dropped product will never block the sensor.

Improve user-friendliness and safety

Along with process and robot optimization, it is valuable to talk to your operators. Ask about their experience with the pick and place robot. They can give useful insights in whether the user-friendliness should or can be improved. Are your operators fully able to work with the pick and place robot? Do they need additional training? Are the user interface and user manuals clear enough for them?

Moreover, acknowledging safety is crucial as well. Is the safety of and around the robot in order? Can improvements be made? Data monitoring can help regulate safety. Especially if you have implemented a cobot solution, data such as collision occurrence can be useful. If camera images are recorded, it is even easier to determine any safety issues.

Besides data monitoring, have your warehouse personnel register any unsafe situations regarding the pick and place robot or cobot. It can enable you to determine what adjustments are needed, either at the robot itself or by creating safety warnings, adjustments in the user manual or by supplying personal protective equipment to your employees.

Predictive maintenance

The hardware of the robot is another element where you can optimize performance and ensure smooth operation. At some point wear and tear will result in having to maintain or replace hardware items. The question is; will you wait till a part is broken and needs to be replaced, resulting in downtime of the robot, or will you replace parts before the hardware malfunctions?

Predictive maintenance is where you use data available to predict when a hardware part needs to be replaced or maintained. For instance, if it is known that the gripper of the robot will show cracks and perhaps break after a certain number of picks, that can be prevented by replacing the gripper before that number of picks is reached. Predictive maintenance can be executed during off peak hours to ensure minimal impact on your warehouse fulfillment process.

Naturally, predictive maintenance is very dependent on the situation. For example, a suction cup of a gripper wears quicker on cardboard than on plastic. Again, a reason why data monitoring is so vital. It allows you to learn the pattern of wear and tear of your hardware items and optimize your predictive maintenance process. Eventually, that will result in a more continuous, efficient and smooth operation.

Ready for the warehouse of the future?

Improving your warehouse fulfillment process with pick and place robots is a process that takes time and effort, but in the end it will benefit your company greatly. Pick and place robots are the next step into the future and will help you overcome labor challenges, increasing consumer demand and realize cost savings. Smart Robotics is your Pick & Place Partner we offer various picking solutions to improve your warehouse fulfillment process. We can assist in processes such as order picking, goods to sorter, parcel unloading and palletizing. Our pick and place robots are reliable, easy-to-use, adaptable and can handle a large variety of items. This enables you to make your operation much more efficient and to scale up your business.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Download our free white paper

Learn how to implement the ideal pick & place robot in your warehouse. Leave your contact details and receive a download link to our free white paper.