Table of Contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Robotic vs gantry palletizers: which one best fits your business?

Table of Contents

If you work in production, manufacturing, or logistics, a big part of your end-of-line process is probably palletizing. But a question remains: with all the options available in the palletizing market, which palletizer is right for your business?

Considering factors like space available in your facility, budget, speed and throughput needs, this article will dive into which palletizers can do what, and which one is right for your business.

What is a robotic palletizer?

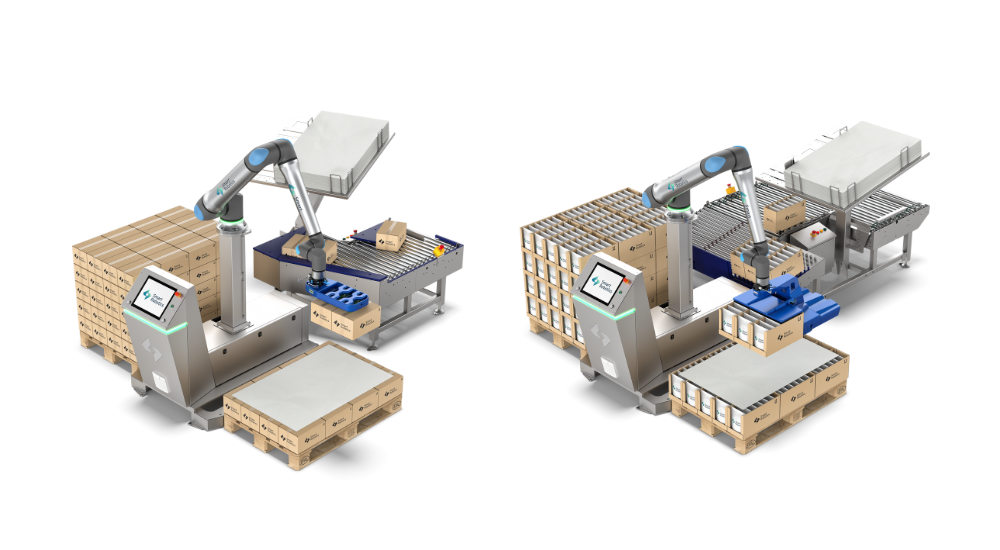

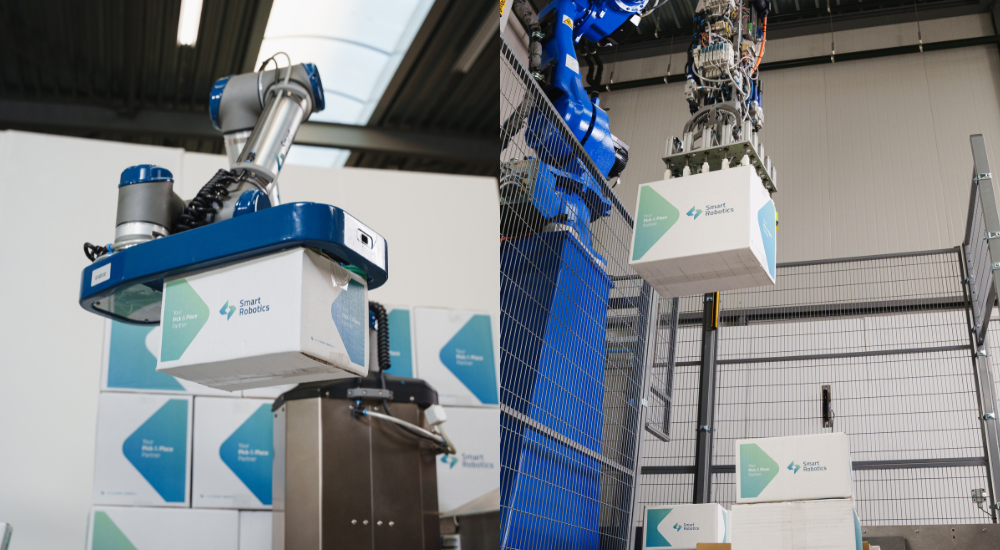

A robotic palletizer is an automated system that uses a robotic arm to stack products such as boxes, cartons or bags onto a pallet. The system combines intelligent software with precise hardware to grip, lift and place items in a defined stacking pattern, offering a flexible and efficient solution for end-of-line automation.

Key features of a robotic palletizer:

Robot arm: To stack products neatly and reliably, a 6-axis robotic arm is typically used. It gives the flexibility needed to move and orient each product into the right position on the pallet.

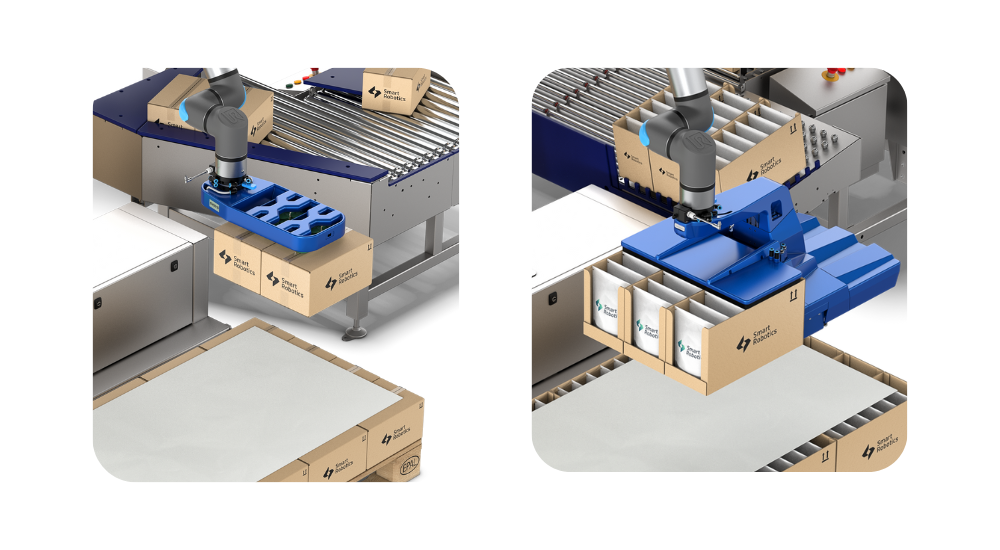

Gripper end-effector: Often referred to as the hand of the robot, the end-effector gripper uses suction to lift products. Most robotic palletizers use either a vacuum or forklift-type gripper to handle different types of cases, whether they’re open, closed, taped, or glued.

Sensors: Robotic palletizers use AI-driven sensors to avoid collisions and handle products gently. Force and proximity sensors help the robot understand how firmly to grip a box and how close it is to the product before picking it up.

Software: Every palletizing system relies on software to control the robot’s movements. These movements are configured based on product size, weight, stacking pattern, and any specific palletizing needs.

At Smart Robotics, we’ve developed our software in-house to give customers full flexibility, whether they need a single setup today or want to scale and adapt in the future.

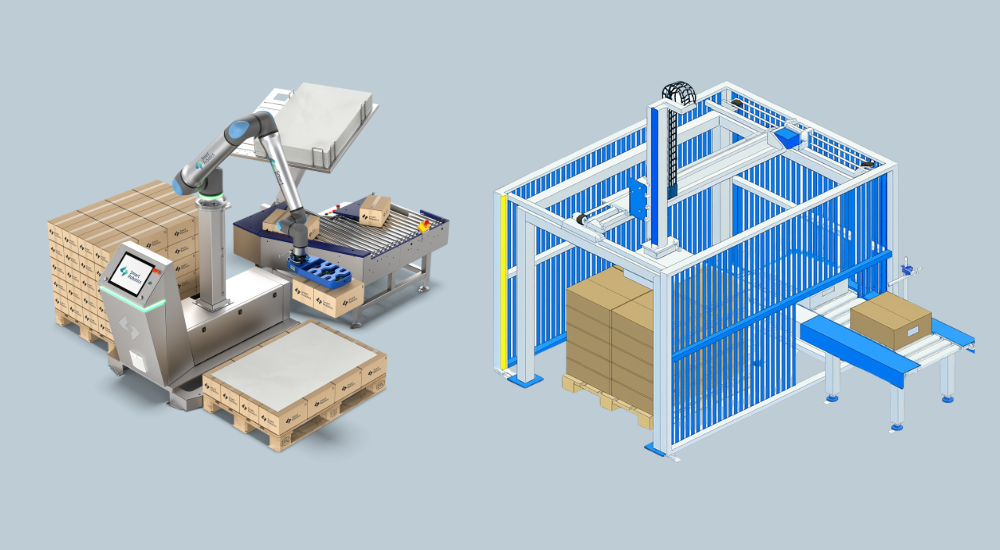

What is a gantry palletizer?

Unlike robotic palletizers, gantry palletizers use components like conveyors and pushers to arrange items into layers before stacking them on a pallet.

They’re typically built for high-throughput palletizing (often 2,000 cases per hour or more) and work best with products that stay the same in size and weight. But if anything changes, like the product dimensions or stacking pattern, reconfiguring the system is usually complex and takes time.

Key components of gantry palletizers:

Frame: The frame is the mounted structure that supports and allows the movement of the system along the X, Y, and Z axes. Typically, it is installed above the work area to give the gantry access to multiple pallet positions across the workspace.

Linear drive system: This system controls the linear movements of the gripper or tool head.

Gripper: The gripper is known as the “hand” of the machine. Most gantry systems use a vacuum or clamp-style gripper to pick up products and place them onto the pallet.

Product infeed conveyor: This conveyor moves products to the pickup zone. It works in sync with the gantry to make sure each item is in the right position at the right time.

Pallet station: This is where the gantry stacks products. Some systems support multiple pallet stations to reduce downtime.

Controls and software: The software manages everything from movement to stacking patterns and system configurations. It’s the core of the operation and can be adjusted to match your specific palletizing needs.

Safety area: Gantry palletizers are not collaborative systems, so they require safety fencing or barriers around the work area to protect operators during operation.

What are the pros and cons of robotic palletizers?

Now that we’ve covered what robotic palletizers can do, it’s worth looking at the benefits and drawbacks of using one.

Benefits of a robotic palletizer

Highly flexible systems: Robotic palletizers adapt easily to changes in product size, weight, or stacking pattern. If you introduce a new SKU or switch to a heavier box, the system can be quickly reprogrammed to handle it with no gantry changes needed.

Small footprint palletizer: Compared to gantry palletizers, robotic palletizers take up far less space. A typical setup fits within 2.5 x 3 meters, while gantry palletizers often need 8 x 5 meters or more. That larger footprint includes the space needed for layer-forming zones, pushers, conveyors, and safety access areas.

A typical setup fits within 2.5 x 3 meters, while gantry palletizers often need 8 x 5 meters or more. That larger footprint includes the space needed for layer-forming zones, pushers, conveyors, and safety access areas.

Safety: Robotic palletizers that use collaborative applications comply with ISO 10218-2 and are safe to use.

They slow down when someone comes close and stop if they come into contact with anything unexpected, like an operator. They also reduce the need for manual picking and placing, which helps prevent strain and back injuries on the work floor.

Lower maintenance and costs: Robotic systems are compact, have fewer moving parts (like pushers and conveyors), and run on simpler software compared to gantry machines. As a result, they experience less wear and tear and typically require less maintenance over time.

Drawbacks to owning a robotic palletizer:

Cost of investment and operation: Both gantry and robotic palletizers require a similar upfront investment, though robotic systems typically cost less to maintain over time. Robotic systems also take up less space and are easier to adapt, which helps reduce the overall cost of ownership.

Requires professional setup: To set up a robotic palletizer properly, programming expertise is needed.

At Smart Robotics, our service team handles that from start to finish. From the moment the system is approved to the moment it’s up and running at the customer’s site, the team makes sure everything works as it should and stays that way.

Payload limitations: Robotic palletizers using cobot applications typically handle up to 30 kg per product.

That’s more than enough for most operations. But if you need to lift products heavier than that, you can look into mixed-case palletizers that are designed for higher payloads and stacking different product types on a single pallet.

Gantry palletizers are also an option, but they don’t offer the same flexibility as robotic or cobot systems.

Robotic palletizers vs gantry palletizers

Compared to traditional gantry palletizers, robotic palletizers offer a far more flexible and space-efficient solution. While gantry systems are rigid and limited in their application, robotic palletizers are easily programmable and highly adaptable to different product types and layouts.

They require minimal maintenance, consume less energy, and can deliver a return on investment within 6 months to 2 years, significantly faster than the 2–5 years typically seen with gantry setups. For businesses seeking a compact, future-proof palletizing solution with lower long-term costs, robotic palletizers offer a practical option.

Which palletizer is right for your business?

Palletizing needs depend on your products, output targets, and the space you have available. Gantry palletizers are often used for high-speed stacking of uniform products, but they’re difficult to adapt when products change.

That’s where robotic and cobot palletizers have the advantage. They can handle different case sizes, stacking patterns, and workflows with minimal setup time. If you’re scaling up, updating SKUs, or working in a tighter space, a robotic palletizer offers the flexibility and ease of use that fits most operations today and tomorrow.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Frequently Asked Questions

The key difference between robotic and gantry palletizers comes down to payload, flexibility, and footprint. Robotic palletizers take up less space and are ideal if your line needs to change or scale. They handle lower payloads per product than gantry systems, but offer more flexibility. Gantry palletizers, on the other hand, are built for heavy lifting and high-speed stacking of uniform products. They rely on conveyors and pushers to form layers; systems that require more space and are harder to adapt when your product mix or layout changes.

Robotic palletizers are best for small spaces. A typical system fits within 2.5 x 3 meters. Gantry palletizers often require more than triple that, with added space for conveyors and safety zones.

Yes, robotic palletizers using collaborative applications slow down or stop when someone approaches. They’re designed to be safe without the need for fencing, helping teams keep operators safe.

Gantry systems move in straight lines (X, Y, Z) and are built for fast, repetitive stacking of uniform products. On the other hand, robot arms offer full-range motion and are better suited for flexible palletizing with changing case sizes or layouts.