Table of Contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

What does the total cost of ownership (TCO) look like in automation?

Table of Contents

When considering automation, one of the first questions potential buyers ask is: How much will it cost? Not just the upfront investment, but the long-term costs too. Are there recurring expenses that keep showing up year after year?

Understanding the total cost of ownership (TCO) in automation is key to making informed, confident decisions before committing to any investment.

TCO includes all costs tied to the system, both at the time of purchase and in the years that follow. That means development, implementation, maintenance, support, and any ongoing services needed to keep things running smoothly.

By looking beyond the initial price tag, organizations can evaluate whether an automation solution will deliver lasting value and truly meet their operational needs.

In this article, we’ll break down what TCO means in the context of automation, drawing on our 10+ years of experience in the industry.

What’s included in the TCO of automation?

Many cost factors come into play when calculating the total cost of ownership. Let’s look at what’s involved:

System costs

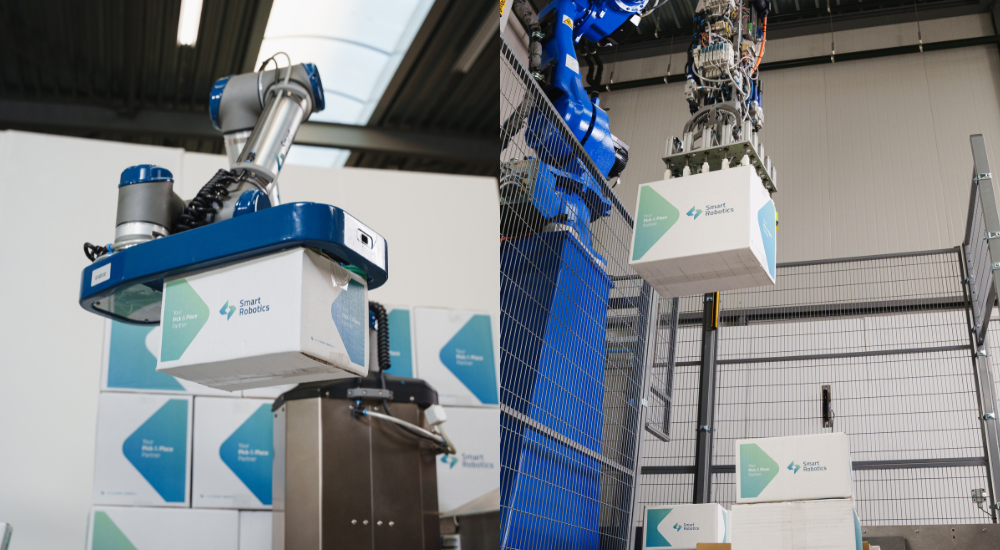

The first thing that comes to mind when thinking about automation is the system itself: the hardware and software. In the case of (de)palletizing and item picking systems, this includes components like the robotic arm, gripper, and frame. In some cases, conveyor systems are also part of the automation solution and are included in the system costs. However, if the robotic system needs to connect to your existing conveyor setup, that would fall under integration costs.

And of course, none of it works without the right software. That’s where our in-house development team comes in. Thanks to their work, the system is easy to set up and ready for installation straight away.

Integration costs

Of course, a system on its own isn’t enough. You also need to factor in how it integrates with your current setup, or the one you’re aiming for.

Want the system to connect with software like WMS or hardware like AutoStore? That comes under the umbrella of integration costs.

Installation, maintenance, and training costs

Getting the system up and running properly at your site is key to a successful automation project. Training your team to operate the system and troubleshoot basic errors is just as important to keep everything running smoothly.

If you’re working with Smart Robotics, you don’t need to worry about separate training fees. We believe it’s essential to train your team on how to use the system when you purchase from us.

Maintenance costs help ensure your system continues to perform well for years to come. This includes preventive maintenance and software updates, if needed.

Servicing and helpdesk

In the unlikely event that the system stops and your team can’t fix it, our customer success team is ready to help. If you choose to subscribe to our online service and helpdesk, we can jump on a call or even resolve the issue remotely through our connection to the system.

In fact, more than 9 out of 10 calls are fixed on the spot. This helps our customers keep uptime high.

Are TCO and ROI related?

Yes, the total cost of ownership (TCO) and return on investment (ROI) are closely related. If you can identify the TCO of a solution, it becomes much easier to calculate the potential ROI for your business.

Of course, TCO is not the only factor when determining ROI. Things like time and money saved by the organization, fewer employee shifts, and increased production output also contribute to the overall return.

Curious about the TCO for your business?

If you’d like to calculate the total cost of ownership for automating a process like palletizing, depalletizing, or item picking, feel free to reach out. Our experts are happy to help you explore whether automation is the right fit, and what kind of return you can expect.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Let’s Calculate the Total Cost of Automation for Your BusinessGet Started Today

FAQs

Typical TCO costs for automation include:

- System costs, including hardware and software

- Integration costs – connecting with an existing or new set-up (e.g., WMS, conveyors)

- Installation – setup and deployment

- Maintenance – regular servicing, software updates, and preventive maintenance

- Support and service – helpdesk access or on-site assistance if required

TCO refers to the complete cost of an automation solution over its full lifecycle. It includes not just the upfront price, but also all related costs such as installation, integration, training, maintenance, and ongoing service. TCO helps companies assess the long-term value and return on their automation investment.

TCO provides the full picture of costs needed to calculate ROI. By understanding all costs involved, companies can more accurately assess how automation improves productivity, reduces labor costs, and enhances throughput over time.

Ways to lower TCO include:

- Choosing systems with built-in remote support and low maintenance requirements

- Ensuring flawless integration with your worflows during installation and set-up

- Providing thorough operator training to reduce errors and downtime

- Partnering with vendors that offer long-term service agreements