Table of contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

What is a pick and place robot? An in-depth guide on their functionality & types

Table of contents

What is a pick and place robot?

Simply put, pick and place robots are a category of industrial robots designed to efficiently lift objects from one location and place them in another. They have been around since the 1960s, and today, pick-and-place robots are a staple in modern warehouses, automating tasks that range from complex operations to simple, repetitive ones.

Renowned for their speed, accuracy, and efficiency, pick and place robots have become indispensable in industries such as manufacturing, packaging, and logistics. They have also significantly reduced workplace injuries by taking on hazardous tasks traditionally performed by humans, such as stacking heavy parcels and packages.

In this article, we’ll dive deep into what is a pick and place robot, how they work, and why they could be the ideal solution for your business.

How pick and place robots work

While the concept may seem simple, pick and place robots are highly complex, with thousands of interconnected mechanisms working together in mere seconds to identify, grasp, and move objects from one location to another.

Sensors or cameras detect the object’s position, size, and orientation, allowing the pick-and-place robot to calculate the most efficient path to reach it while avoiding obstacles. Using end-effectors (often referred to as the “hands” of the robot), the robot grasps the item securely, transports it to the designated location, and places it with great precision.

While software provides the base for intelligence and precision, the physical components—such as the robotic arm, sensors, and end-effectors—are equally crucial for executing tasks with speed and reliability.

The origins of pick and place robots

The origins of pick and place robots can be traced back to the early 1960s, when American engineers George Devol and Joseph Engelberger introduced the world’s first industrial robot, the Unimate.

This robot was designed to transport die castings from assembly lines and weld them onto auto bodies, tackling tasks that were notoriously hazardous for human workers. Its release in 1961 marked a turning point in industrial automation, inspiring engineers to develop safer and more efficient manufacturing solutions for the years to come.

Key components of a pick and place robot

While software provides a strong foundation for pick-and-place robots, it is meaningless without the hardware’s capabilities and flawless integration between the two.

Here is how the hardware and software components come together to form efficient pick and place robots:

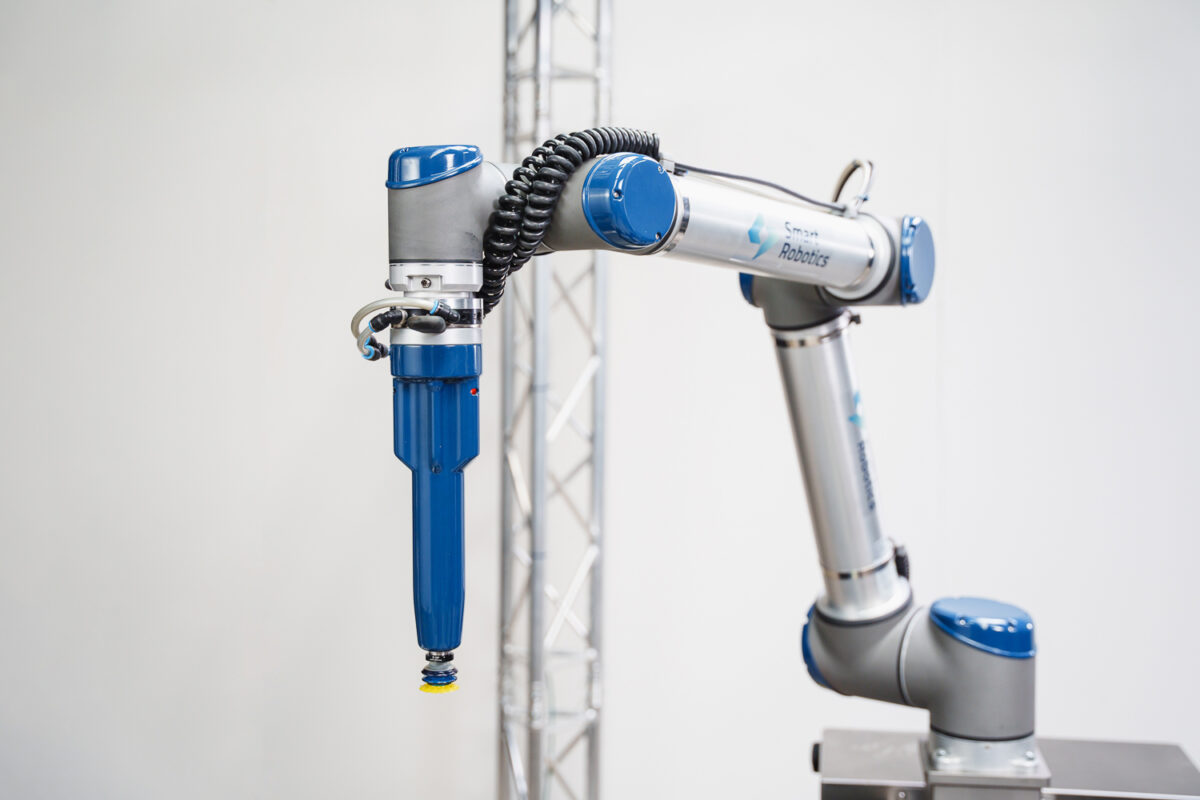

1. Robotic arm

Depending on the type of robot, the arm is typically designed to minimize cycle duration—a critical metric that measures the time it takes for the robot to start, complete a task, and return to its starting position.

The robotic arm, though a system in itself, is just one part of the overall pick-and-place solution. Factors such as the warehouse’s space, required capabilities, item volume, and reachability determine the selection of a robotic arm to efficiently move items from point A to point B.

Once the hardware design is finalized, the robot is programmed and integrated with sensors, controllers, end-effectors, and other essential components, enabling it to perform tasks with speed and precision.

2. End effectors

End effectors function as the “hands” of robotic arms, serving as the point of contact between the robot and the object it interacts with. The design of the end effector varies depending on the types of objects needed to be handled. Common types include:

Vacuum grippers: Uses suction to pick up sealed items or boxes. However, this type of gripper is not suitable for open or porous boxes.

Mechanical grippers: Finger-like clasps designed to handle objects of various shapes and sizes. Keep in mind, these grippers require open space around them to function effectively.

Magnetic and Adhesive grippers: Ideal for handling heavy iron or metal objects, often used in production lines.

3. Sensors

Sensors are critical for guiding and ensuring the pick-and-place robot’s precision. Different types of sensors serve unique purposes:

Vision sensors: These are sensors equipped with 2D or 3D cameras, allowing the robot to “see” and identify objects, guiding it on what to pick and how to grasp it. Our custom-engineered vision software identifies items without SKU teaching and uses artificial intelligence to learn from each pick, improving accuracy and ensuring collision avoidance.

Force sensors: Found in the end effector (the “hand” of the robot), these control how hard the robot grips an item, preventing damage to delicate objects. Force sensors also measure an item’s weight to ensure the robot handles the correct quantity based on the predetermined number of items specified in the system.

Proximity sensors: These sensors detect obstacles or objects in the robot’s workspace, ensuring it avoids collisions with items or human operators.

4. Controllers & movement control

Controllers act as the CPU or brain of the pick-and-place robot, flawlessly combining hardware and software to execute actions. They process input from sensors to determine the robot’s next moves.

At Smart Robotics, we’ve developed our own motion and task planning technology, much like our vision software, to work in harmony with sensors. This integration allows the robot’s intelligence to choose the fastest path and handle tasks like vision processing while on the move. This not only accelerates cycle times and boosts throughput but also ensures gentle product handling.

Additionally, our task planning software adjusts the robot’s speed based on its surroundings—increasing speed when no human operators are nearby and slowing down when human operators are detected in the vicinity, ensuring safe and controlled operation.

Types of pick and place robots

There are several different types of pick and place robot types, including:

Robotic arm: A robotic arm is one of the most common types of pick-and-place robots. A 5-axis robotic arm moves items from one place to another in a relatively straight line. A 6-axis robotic arm can twist and turn objects, making it ideal when items need to be repositioned before placement. This works especially well for applications like palletizing and item picking, which we produce in-house.

Cartesian robots: Named after the Cartesian coordinate system, these robots operate on three axes – X, Y, and Z. They are widely used for tasks requiring high precision and reliability without the need for complex movement, such as in electronics and automotive assembly. They are also commonly used in 3D printing and CNC applications.

Delta robots: Also referred to as spider robots, these machines consist of 3 arms connected by a joint at the bottom. Delta robots are known for their speed and are primarily used in food sorting, product assembly, dispensing, and material handling.

Collaborative robots (Cobots): These robots are designed to work safely alongside humans and feature the highest number of axes. Cobots are incredibly versatile, capable of perforection:ming a wide range of tasks, which makes them ideal for industries like logistics, e-commerce, fashion, food, and pharmaceuticals. At Smart Robotics, we specialize in providing cobots for various pick-and-place tasks, including palletizing and item picking.

Industrial robots: Unlike cobots, industrial robots are not designed to safely work alongside humans and are typically enclosed within fences to prevent workers from getting in contact. They are renowned for their ability to handle high payloads and operate at high speeds, making them ideal for tasks such as depalletizing in logistics facilities or assembling goods with precision.

Applications of pick and place robots

Pick and place robots can operate in various modes depending on the task requirements. These modes determine how the robot interacts with stationary or moving objects during its operation:

Assembly: Pick and place robots are used to assemble products by moving parts from one location, like a conveyor belt, to another spot where the parts are placed or attached. These robots work by gripping the parts, then accurately positioning and attaching them in the right place.

Packaging: Pick and place robots can be used in packaging applications, such as grabbing items from a stationary or moving area and placing them into a packaging container, like a shipping carton you get when ordering from an e-commerce website.

Bin picking: Pick and place robots can pick items from bins containing a variety of shapes, sizes, and colors. This is possible thanks to advanced vision systems that help the robot identify and select the right parts. After picking, these items are then moved to another location for assembly or packaging.

Inspection: Thanks to advanced vision systems, pick and place robots can identify defective items and remove them from the good batch. They can then sort these defective parts into a separate bin or path, based on the client’s requirements.

Axes in pick and place robots

Pick-and-place robots have 3 to 6 axes, allowing a range of motion for complex tasks. The number of axes defines the robot’s flexibility and ability to maneuver in an open space.

Advantages of pick and place robots

In a nutshell, pick-and-place robots are fast, reliable, and offer a high return on investment, making them an excellent choice for scalability as businesses grow. They also help address labor shortages in manufacturing and production while enhancing quality control and efficiency in warehouses.

High return on investment

Pick-and-place robots are typically much faster and operate more consistently than humans, helping businesses exceed their key performance indicators (KPIs), such as throughput and order fulfillment, while significantly reducing labor costs by automating repetitive tasks. The robots’ precision also minimizes errors, waste, and product damage often associated with human operators. As a result, businesses typically achieve a high return on their investment.

Labor shortage relief

As traditional office jobs evolve in our increasingly digitalized world, more people are choosing to leave physically demanding jobs, often tied with minimum wage salaries. With a shrinking labor force and growing demand for fast-paced production, automation with robotics has become the sole solution for many companies worldwide.

Efficiency and high-quality control

Pick place robots can be more efficient than humans, operating almost 24/7 without the need for breaks, sick leave, or any holidays. Being mounted on a fixed ground, they also reduce the warehouse footprint when delivering products to customers. Additionally, because they are programmed to perform tasks in a specific, custom-designed manner tailored to the customer’s needs, they significantly minimize the errors typically made by employees.

Are pick and place robots right for your business?

If you work in logistics today, there’s likely a solution just around the corner to help you automate repetitive tasks. Take Vandemoortele, for example—a leading European food manufacturer—who automated their outbound process using the Smart Palletizer. With our solution, they achieved a return on investment in less than a year.

So, whether you work in manufacturing or a production warehouse, there’s probably a manual, repetitive task just waiting to be automated.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Download our free white paper

Learn all about how to implement a pick & place robot in your warehouse. Download our free whitepaper and find the ideal pick & place robot for you.