Efficient and accurate item picking

With the Smart Item Picker we can help overcome various challenges in your warehouse or fulfillment process. The Smart Item Picker serves customers in markets such as Apparel, Cosmetics, Healthcare, Toys, Pharma and E-commerce to overcome:

- Growing Labor shortages

- Increasing consumer demand and variety

- Need for efficiency whilst decreasing operation costs

- Growing need to comply with strict health and safety legislation.

- Dissatisfied employees and high turnover rate due to boring, repetitive and physically straining work

Global leaders use Smart Robotics to automate their operations

Item Picking Integration Options

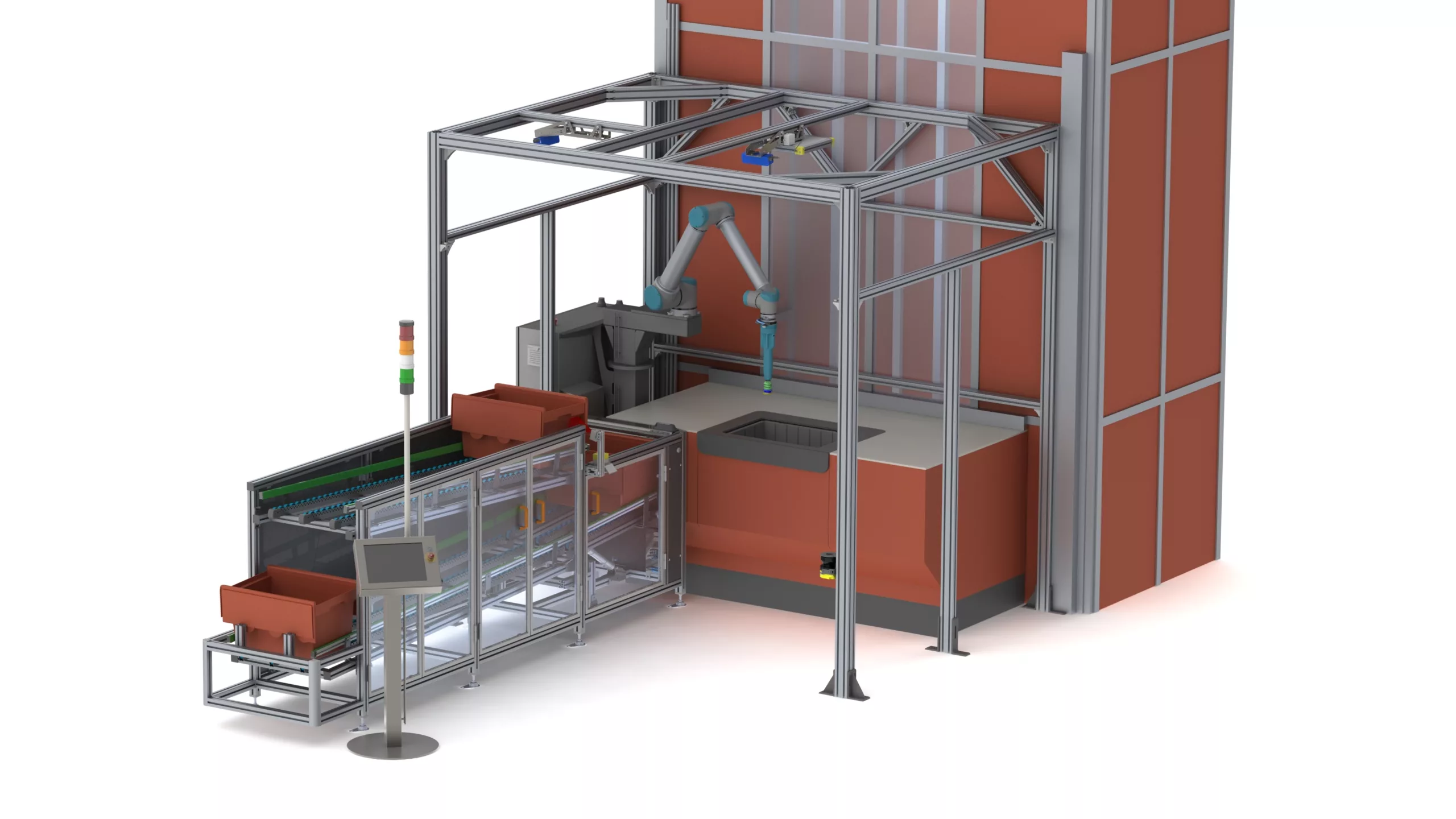

Order Picking (Goods to Person)

Robotic item picking from cube storage, shuttles, AMRs, and other ASRS.

- Cube Storage

- Autostore

- Shuttles & other ASRS

- AMRs (Autonomous Mobile Robots)

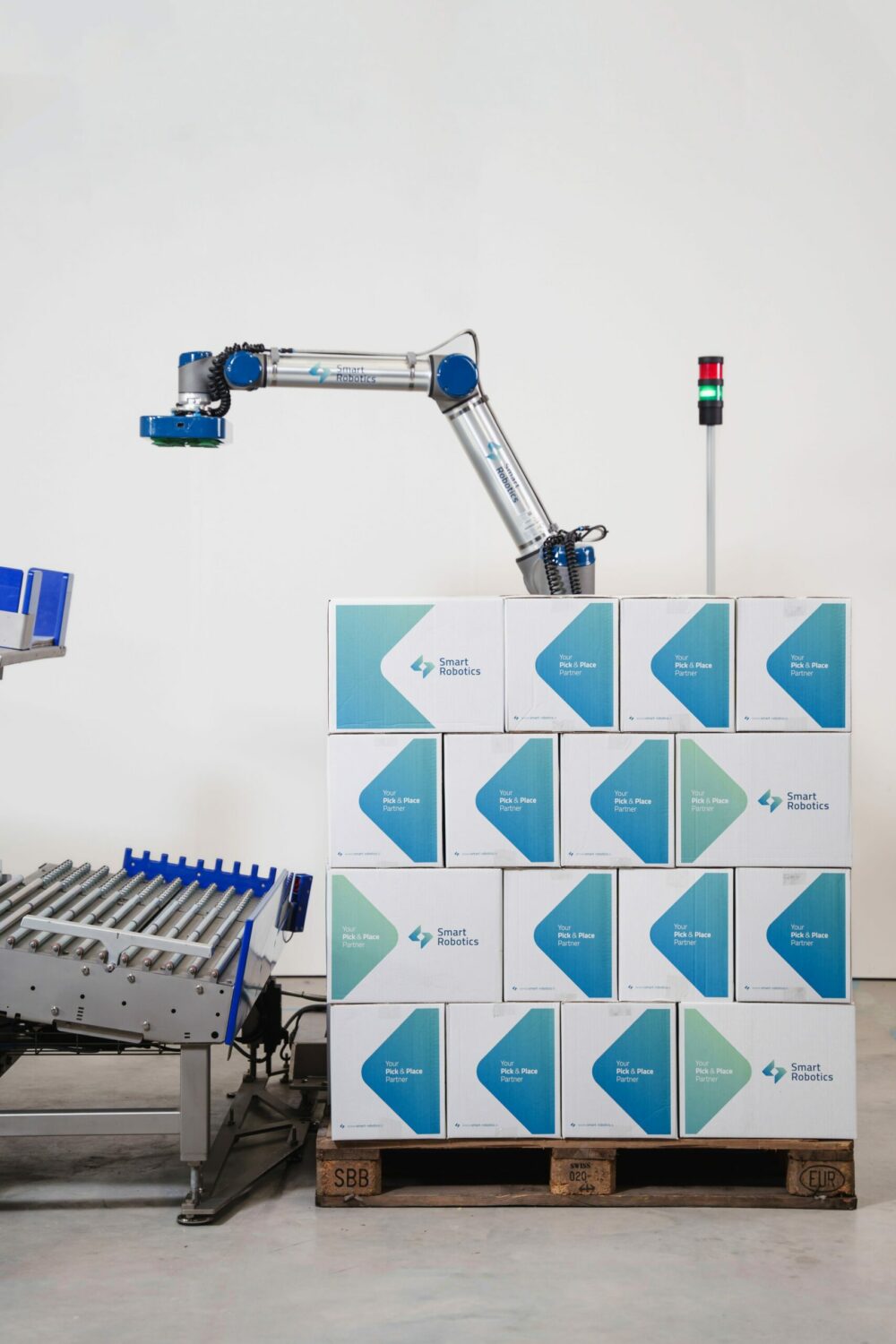

Order Packing

Automated item picking to packing stations and conveyor systems

- Packing Stations

- Conveyor Systems

Order Inducting

Automated induction onto sortation systems, auto-bagging, or pocket systems.

- Sortation Systems

- Auto Bagging / Pockets

Our Smart Item Picker integrates seamlessly with a wide range of order picking systems, including Cube Storage, Autostore, various Automated Storage and Retrieval Systems (ASRS), and Autonomous Mobile Robots (AMRs). It also supports order inducting and packing solutions such as sortation systems, auto bagging, and conveyor systems, thereby enhancing the efficiency and accuracy of your e-commerce fulfillment operations.

Are you ready to reduce labor costs and scale up orders?

Top Features

High Throughput

Handles up to 1000 items / hour

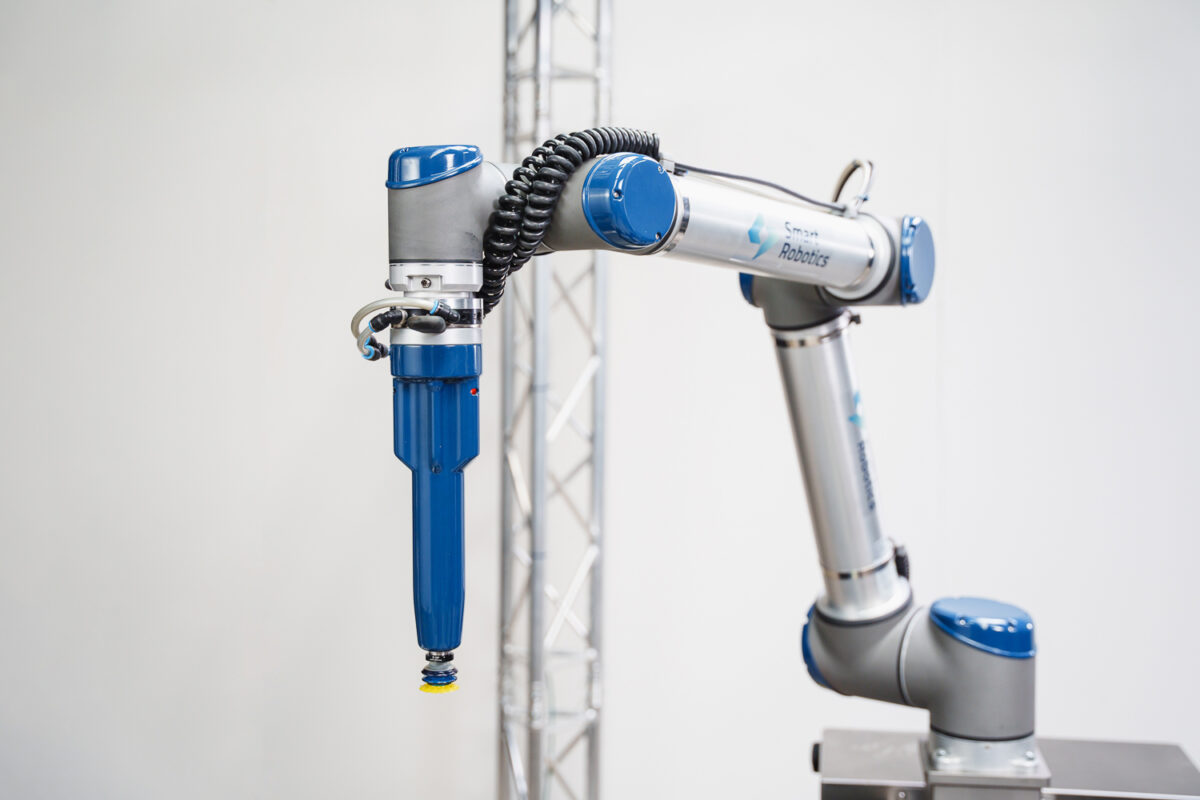

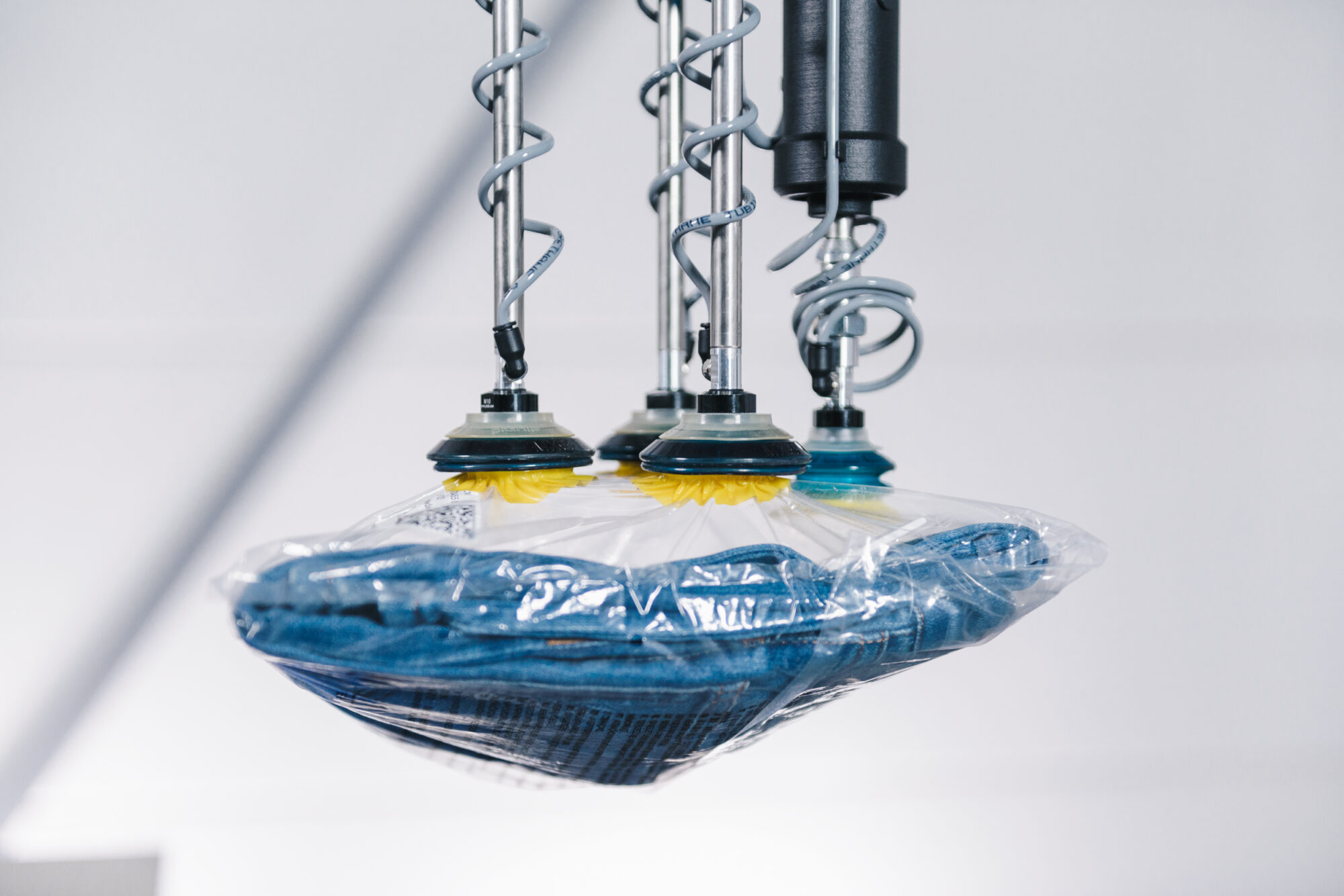

Gentle Item Handling

Minimizing the risk of item damage during the process

Item Weighing

Checks item weight & picks above 5 kg

Barcode Scanning

Accurate barcode identification

Smart Item Picker Benefits

High level of performance & reliability

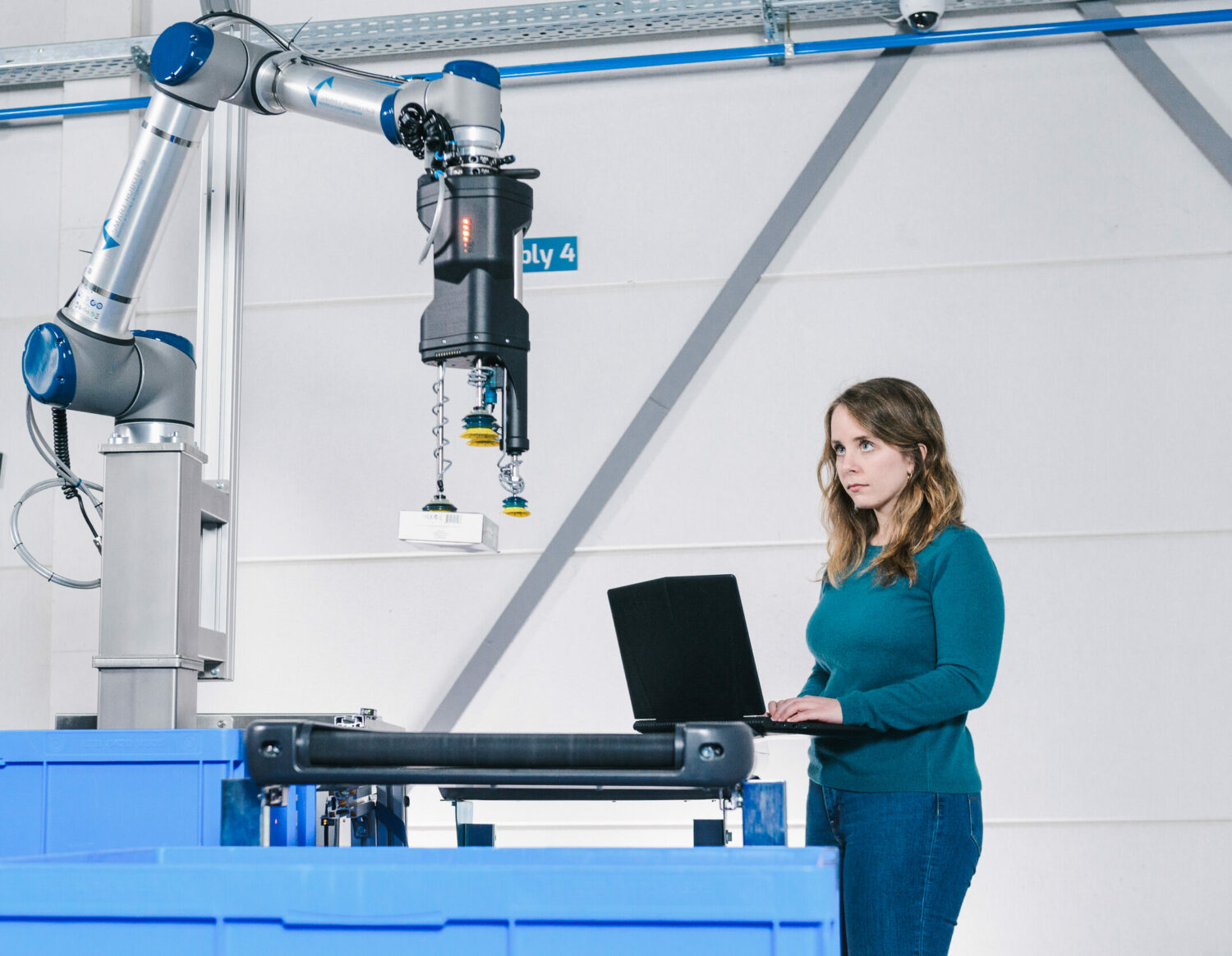

Can pick and place a large variety of items without the need for SKU teaching and is easy to use by any operator. It allows for safe cooperation with people. Our remote monitoring & reporting ensures reliable performance.

High level of learning & adaptability

Our AI software learns and adapts continuously to improve efficiency and productivity, resulting in optimal performance and high throughput.

High level of flexibility & scalability

Can easily be integrated within your WCS/WMS and connect with Automated Storage and Retrieval Systems such as Autostore. It is suitable for various fulfillment processes; from order picking, packing to inducting.

High level of service & ROI

We offer picking automation as a service: hardware, software and service included. Our Online Helpdesk and dedicated customer service team ensure reliable and continuous operation resulting in an ROI.

Automated Item Picking

Watch video

Pick & Place customers

Discover how our customers have improved their production and fulfillment processes with a reliable and efficient pick and place solution.

Did you know that Bol.com, one of the largest Dutch online retail & distribution companies, executed a pilot with Smart Robotics regarding the implementation of a Smart Item Picker?

Read more >

“With our extensive range of products, a picking application must know really well what products it picks and how to place them correctly”

“With our extensive range of products, a picking application must know really well what products it picks and how to place them correctly”

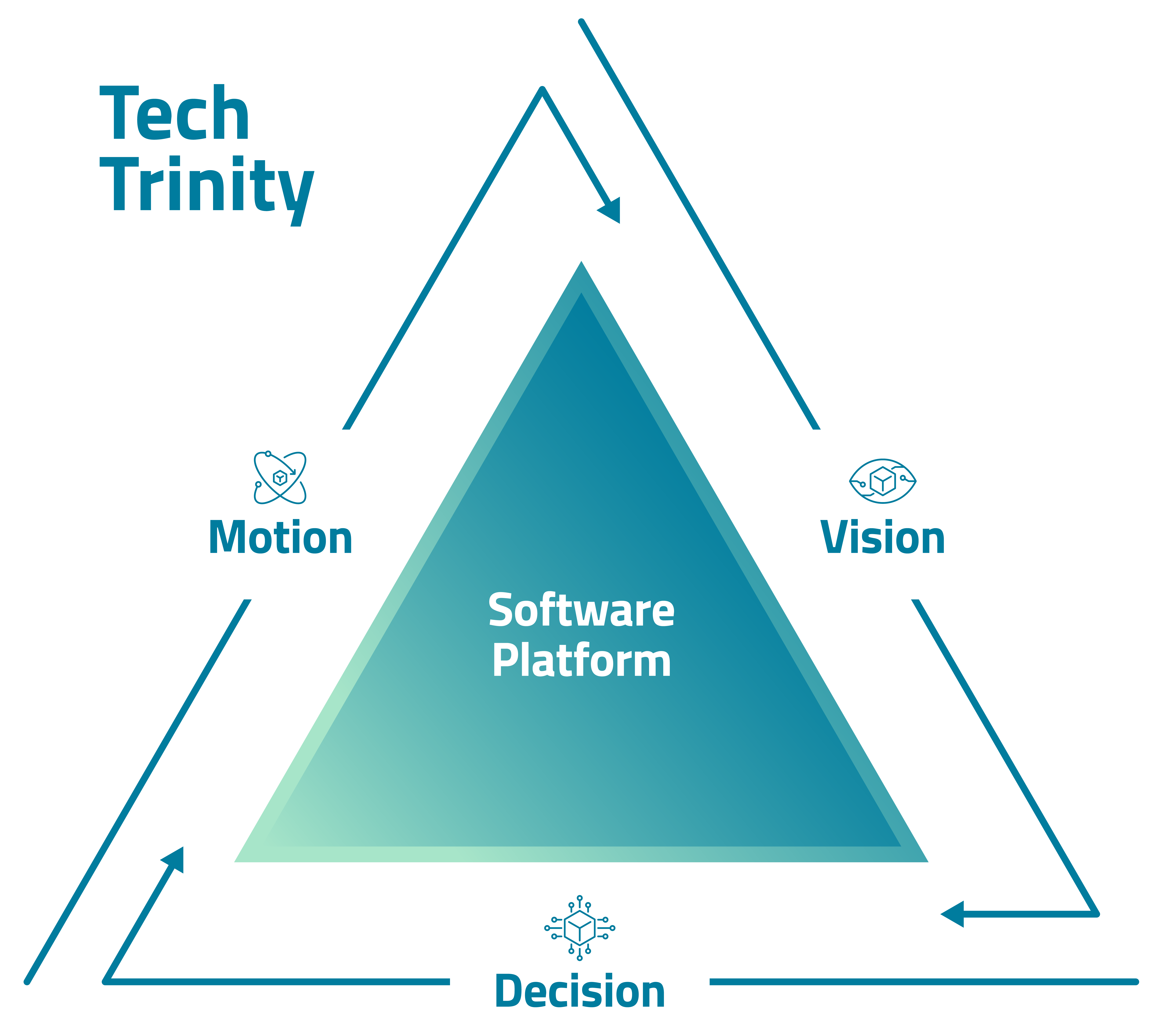

AI Vision Motion and Decision

Our Pick & Place solutions are built for flexibility, configurability, and robustness, ensuring you meet and exceed your KPIs. Through our technology trinity the combination of advanced AI Vision, Motion, and Decision-making algorithms, our Smart Item Picking solutions easily adapt to dynamic workflows and consistently deliver under unpredictable conditions. They adjust to changing workflows, maintaining high accuracy and optimizing container filling for different products.

FAQ

Smart Item Picker

A pick and place robot or picking robot is a system used to automate the process of picking up products or items and placing them in a different location.

Read more about pick & place robots>A pick and place robot is a system consisting of a robot or cobot arm, gripper and intelligent software for the picking and placing of products.

Read more about pick & place robots>Automating your warehouse with a pick and place robot will increase output and improve quality of work.

Read more about pick & place robots>A pick & place robot offers various advantages that result in high flexibility, improved efficiency and ease of use.

Read more about pick & place robots>A cobot, or collaborative robot, is a type of robot that can safely work together with both people and other cobots.

Read more about cobot palletizers >Have another question? Contact us

More information about item picking

What is a pick and place robot? Types & benefits explained

Discover what pick and place robots are, how they work, their benefits. Learn about types, advantages, and how they improve efficiency, accuracy, and ROI.

Read more

2023 apparel fulfillment trends that emphasize the need for automation

In 2023 there is an increasing need to have a more efficient and sustainable fashion fulfillment process. This blog discusses the fulfillment and logistics trends for the apparel industry in 2023 that emphasize the need for automation.

Read more

Autostore: Transforming Warehousing with Goods-to-Robot Efficiency

Most warehouses already have an goods-to-person system in place. But what if you turn that into a goods-to-robot system? Combining a system such as AutoStore with pick & place robots can help you reach optimal fulfillment throughput and optimize warehouse capacity.

Read more

The top 5 e-commerce fulfillment trends in 2025

Discover 2025’s top 5 ecommerce trends: rising automation, micro-fulfillment centers, same-day delivery, and key insights to help you thrive in a $6.5 billion industry.

Read more

3 signs you are ready for a cobot palletizing colleague

Palletizing can be a repetitive and monotonous task. When are you ready to automate it with a cobot palletizer?

Read more

A robot or cobot in your warehouse? Advantages & disadvantages

There are advantages and disadvantages to both robots and cobots. Learn more about both options to discover which one meets your needs.

Read moreBoost your order fulfillment efficiency with the Smart Item Picker