Table of contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

7 trends shaping the warehouse of the future

Table of contents

With modern warehousing technology evolving faster than ever, it’s crucial to consider what the warehouse of the future might look like. What key factors should you take into account when designing a warehouse? What technologies and solutions can help create a faster, more efficient operation?

In this article, we’ll explore eight key trends shaping the future of modern warehouses.

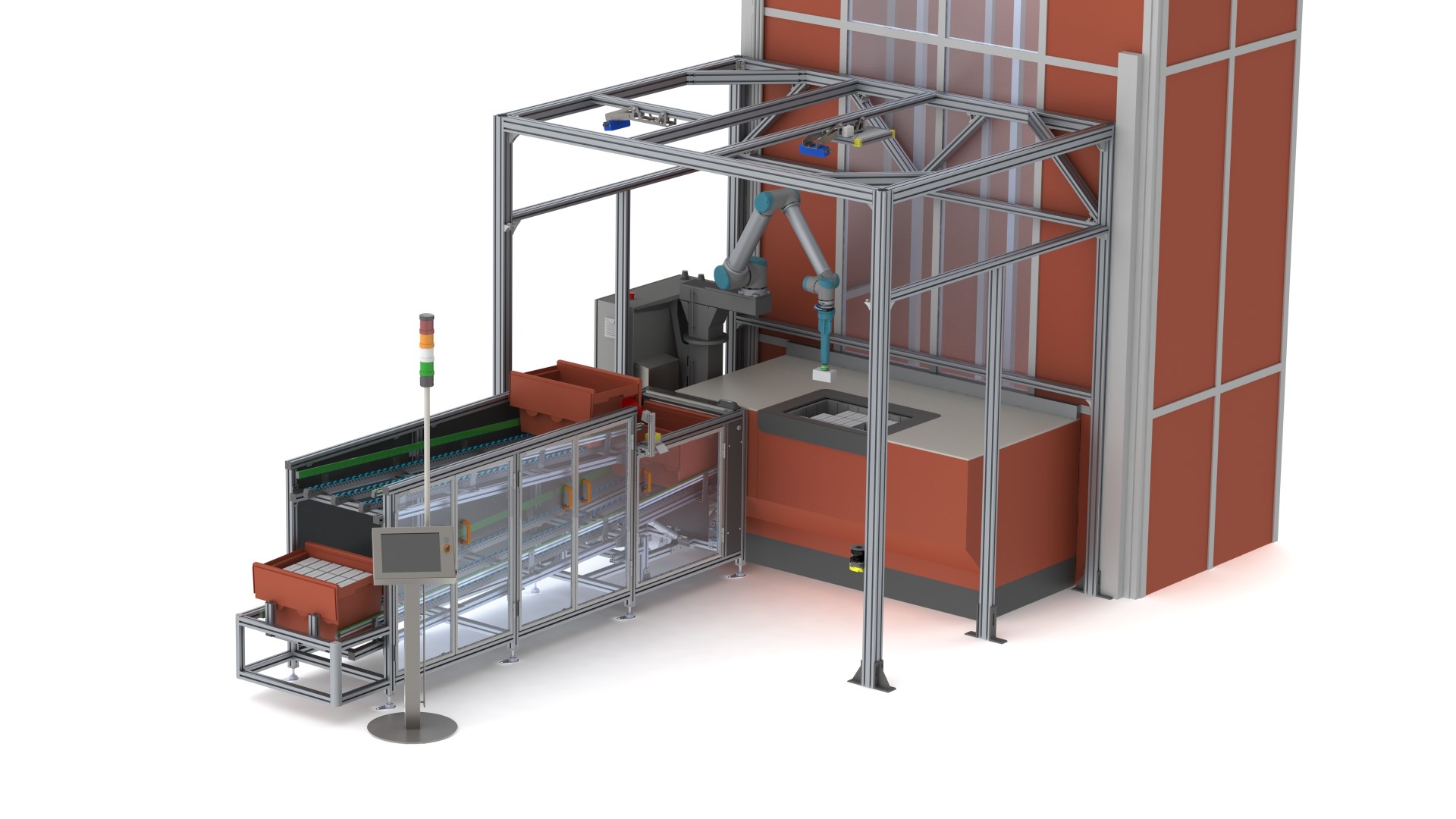

AS/RS and robotic picking arms integration

Automated storage & retrieval systems have been around for almost 60 years. Originally, they were created to increase space capacity within a warehouse while retrieving and storing items with maximum efficiency.

Today, in a world where e-commerce is surging and customers expect to receive orders in less than 24 hours, AS/RS combined with robotic arm integrations has become essential for staying ahead.

Take AutoStore, for example.

When paired with a robotic picking solution that can pick and place items directly into shipping cartons, orders can be packed around the clock—ready for dispatch as soon as workers arrive in the morning.

With robotic picking arms handling 4-6 times more orders per hour compared to manual order packing, it’s a no-brainer that these systems are the future of high-volume, fast-paced warehousing.

Key advantages include increased picking accuracy (error rates reduced by over 99% in some cases), faster fulfillment speeds—particularly in e-commerce—and a reduction in labor costs while handling larger volumes.

The use of AI and IoT for inventory management

Nowadays, the use of artificial intelligence and IoT to manage warehouse inventory is almost inevitable. In fact, this market is projected to grow from $7.38 billion in 2024 to $9.6 billion in 2025, reflecting a compound annual growth rate (CAGR) of 30.1%.

By using IoT-enabled devices such as RFID tags and smart sensors, workers or robots can detect when items need to be replenished, minimizing the margin for error. As a result, warehouses can reduce the risk of overstock and receive real-time restocking suggestions on demand.

Microfulfillment centers and dark warehouses

Unlike traditional warehouses, micro-fulfillment centers (MFCs) are small, automated hubs located near urban areas, designed to quicken last-mile delivery. Microfulfillment centers can reduce order processing times to less than an hour, enhancing the feasibility of same-day deliveries. This shift is driven by the rising demand for instant gratification among consumers and the necessity for businesses to optimize logistics within e-commerce.

Similarly, dark warehouses are also on the rise. These fully automated fulfillment centers operate without human intervention and further exemplify the industry’s move toward fully automated warehouse solutions. Because they’re dark and require no staff rotas, they significantly cut operational costs.

As businesses strive to keep up with escalating e-commerce orders, these automated hubs are set to play a critical role in the future of supply chain management.

3PL and outsourcing

Many businesses are turning to third-party logistics companies, such as DHL, to handle their distribution, warehousing, and shipping. The advantages come in many shapes and forms, such as eliminating the need for capital investment in warehouse infrastructure and providing built-in technologies like route optimization and real-time tracking systems.

While outsourcing logistics to 3PLs offers many benefits, it also comes with a set of challenges, such as increased dependency on external partners and decreased control over operations. Therefore, businesses must carefully weigh these factors and select reputable 3PL providers to ensure alignment with their strategic objectives and maintain supply chain integrity.

Human and robot collaboration (Cobots)

Nowadays, it is completely achievable and safe for robots to work alongside human workers in logistics facilities. These are known as cobots, and they are designed to take over monotonous tasks, allowing businesses to shift their people into more complex and value-adding roles.

That said, the cobot market is growing significantly. In fact, in 2024, the global cobot market reached approximately $1.2 billion, with annual unit shipments exceeding 35,000 robots. Growth was mainly seen among small and medium-sized enterprises, driven by labor shortages, decreasing cobot system costs, and ease of deployment.

At Smart Robotics, we install user-friendly cobots that are designed to plug and play within existing warehouse workflows. Curious how this could work for your organization? Contact one of our warehouse automation experts for a no-obligation meeting to find out.

Employees shifting towards white-collar roles

As mentioned in the previous point, one of the key reasons why employees are dissatisfied working in logistics facilities is the monotonous and repetitive nature of the work. In fact, these repetitive tasks not only waste time but increase the likelihood of errors, ultimately affecting the bottom line.

Thankfully, automation of these tasks means that employers can fill roles that require more creative and technical abilities, such as roles in data analytics, system management, and programming. Packservice, a co-packing company in Germany & Switzerland, found that automating their palletizing improved their employees’ health.

Sustainability in warehousing

With climate change on the rise and consumers placing greater importance on sustainable production, businesses must adapt to stay competitive. Automation has become a key driver of sustainability in warehousing and production. For instance, automating picking and packing processes drastically minimizes errors, leading to fewer damaged or incorrectly shipped products—ultimately cutting down on unnecessary waste and resource consumption.

Conclusion

The warehouse of the future is no longer a distant concept—it’s happening now. From AI-driven inventory management to fully automated fulfillment centers, these advancements are reshaping how businesses operate.

Companies that embrace these trends will be better positioned to meet rising consumer expectations and maintain a competitive edge in an increasingly digital world.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.