Table of Contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

What is palletizing? Types and end-to-end process

Table of Contents

Whether you’ve spent years in logistics or are just getting started, one thing’s clear: palletizing is just one piece of the supply chain puzzle — but it plays a crucial role in getting goods out the door fast and without any unpleasant surprises at their destination.

That’s why, in this article, we’ll walk you through the step-by-step process of palletizing, explore the different types of palletizing solutions, and help you choose the right one for your business.

So, what exactly is palletizing?

Palletizing is the process of systematically stacking large quantities of identical packaged goods (such as taped boxes) on a pallet, ready for shipment. They’re usually stacked in a way that’s stable enough to protect the goods until they’re ready to be taken apart again.

Whether it’s moving boxes of chocolate or crates of pharmaceutical products, palletizing helps goods travel safely through the supply chain.

Many production and logistics companies still rely on employees to palletize manually. That comes with challenges, like employees experiencing back pain from physical work and sometimes needing to quit to regain their health and strength.

This leads to labor shortages and bottlenecks at the end of the production line.

Today, with the rise of automation, more businesses are switching to robotic or cobot palletizers to meet growing demand without putting extra pressure on their workforce.

These robotic palletizing solutions not only solve the challenge of finding labor; they also significantly enhance the efficiency of a facility’s end-of-line operations.

While one employee can palletize 200–300 boxes per hour, a robotic palletizer can easily handle 600–1600 boxes per hour.

Typically, these palletizers, especially cobot palletizers, are compact and don’t take up much space in a facility, so their footprint remains low.

How palletizing works, step by step

Palletizing typically starts with choosing the right pallet, one that can handle the weight and dimensions of your load.

Next, items are arranged in a way that balances weight and maximizes the space on the pallet. Once stacked, the load is secured using straps or wrap to prevent shifting during transit.

The ultimate goal of a palletizer is to keep everything stable and compact on a pallet, no matter how high the stack gets.

1. Pallet selection

Selecting a pallet that’s solid enough for your products heavily depends on the industry you’re in.

Wooden pallets are the most common option across the board. They’re affordable, strong, and used in many industries.

Are you in the food or pharmaceutical industry? Then plastic pallets are the way to go — known for their durability and resistance to moisture, making them cost-effective in the long run.

Metal pallets, while less common and more expensive upfront, are ideal for very heavy or high-temperature loads, like those in the automotive or chemical industries.

If you’re managing a new company and aren’t sure which pallet to choose, it might be a good idea to try out two different types to see which one handles your product best.

2. Arranging the goods and distributing weight

Arranging products properly on a pallet is absolutely critical to ensure they arrive safely at their destination. Typically, heavier products are placed first at the bottom, with lighter ones stacked on top. This prevents the goods on the pallet from tipping over or collapsing.

With a Smart Palletizer, you can control the stacking patterns based on your products and and ensure each pallet is stacked perfectly every single time.

Automating the stacking patterns helps you identify which pattern works best for your load and can be adjusted based on the products on the pallet.

3. Securing the load

After the goods are properly stacked onto a pallet, they need to be tightly secured with straps, shrink wrap, or stretch film to ensure they stay firmly in place during transport.

This is one of the most critical yet often ignored parts of the palletizing process. It’s usually overlooked because once products are stacked neatly, they look secure enough.

However, not using enough shrink wrap can lead to damage during transit, including goods shifting, falling, or getting crushed in the truck.

Best practices include:

- Using enough layers of shrink wrap to create a tight, uniform hold.

- Wrapping all the way down to the bottom layer and overlapping the pallet itself.

- Making sure the wrap is tight enough to compress and secure the load, but not so tight that it damages the boxes.

- Using corner boards or edge protectors to avoid crushing fragile products.

It’s a small step, but it goes a long way in making sure your products arrive safe and sound.

4. Labeling and documenting pallets

The final step in palletizing is labeling the pallets clearly with their contents, weight, destination, and any special handling instructions.

Each pallet also needs accompanying documentation, such as its origin and expiry dates, if applicable.

Good labeling and documentation ensure the pallets are handled correctly, speed up customs clearance, and make tracking goods easier throughout the logistics chain.

The different types of palletizing solutions

There’s no one-size-fits-all approach to palletizing. The best solution for your company depends on factors like your product range, bottlenecks, budget, and future plans.

It also depends on whether you need pallets with mixed products, known as mixed case palletizing, or pallets with just one type of product.

Each solution has its pros and cons, and by understanding these, you can choose the one that best meets your operational needs and efficiency goals.

Robotic palletizing

Robotic industrial palletizers are built for speed and are ideal for applications like mixed case palletizing. They’re well-suited for high-throughput lines where every second counts and goods need to be out the door fast.

These robots are known for their flexibility and precision, easily adapting to different products as needed. They’re a great investment for business leaders looking to future-proof their operations.

However, because they’re fixed in place and require safety fencing to operate, they’re often less flexible than…

Cobot palletizers

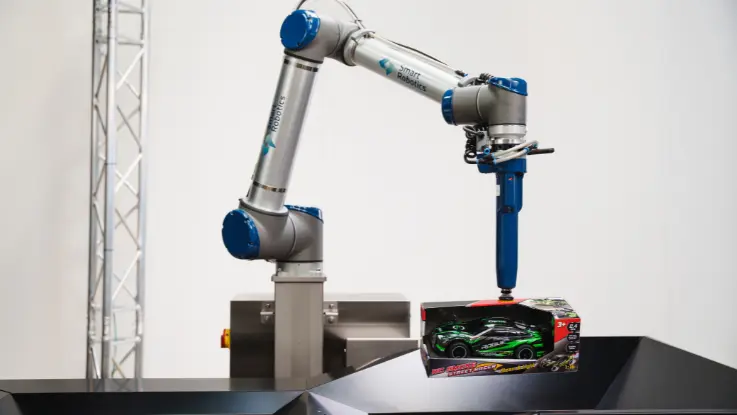

Cobot palletizers, like our very own Smart Palletizer, bring the best of both worlds.

Designed to work safely alongside people without the need for safety fencing, they’re compact, easy to install, and ideal for handling a wide range of box types for a single-SKU pallet. They’re a smart choice for production spaces and warehouses looking to reduce their footprint.

Whether you’re dealing with open crates or sealed boxes, a cobot palletizer can adapt quickly to streamline your end-of-line process. Contact our palletizing experts today to learn more.

Palletizing manually

Manual palletizing is still common in smaller operations. It’s hands-on and doesn’t require much setup, but over time it can take a toll on your team and leave room for inconsistency in your operations, especially with growing labor shortages.

What kinds of products can you palletize?

With the right setup, almost anything. Boxes, crates, open or closed, light or heavy — a wide variety of products can be palletized with ease.

Our Smart Palletizer, for example, is equipped with a unique fork gripper that easily lifts even open boxes. It’s a practical solution trusted by companies in food, pharma, bakery, and more.

Palletizing in action: stacking chocolate at Heinerle-Berggold

Heinerle-Berggold, a German chocolate maker, swapped palletizing manually with a Smart Palletizer to keep up with production and reduce strain on their team.

Installation was quick, and the results were immediate: the palletizer now covers three shifts of manual palletizing. Today, their employees work more comfortably, while the cobot handles the heavy lifting.

Choosing the best palletizing solution for your needs

When selecting a palletizing solution, it’s important to evaluate your specific needs. Product type, volume, available space, and budget all play a role. If your operation handles high volumes and requires flexibility, a cobot palletizer can offer quick setup, easy adaptation, and an ROI in less than a year.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Boost Your End-of-Line Process with Automated PalletizingGet Started Today