Reach uninterrupted fulfillment in the apparel industry with a reliable item picking solution

With rising consumer demand and ongoing labor shortages, the apparel industry is rapidly evolving. Now is the time to implement intelligent and reliable item picking automation to keep operations efficient and competitive.

Read moreCobot palletizer in action

Watch Video

Why automation is key

To address rising labor shortages and ensure uninterrupted fulfillment operations, automation is essential. In today’s competitive apparel market, companies must optimize their processes to improve efficiency, control costs, and scale effectively. Key fulfillment steps like order picking, sorting, and packing can all benefit from automation. That’s where the Smart Item Picker comes in — a reliable, intelligent solution designed to streamline your fulfillment process and keep your business moving.

Read more

Uninterrupted operation

Improves accuracy

Seamless integration

Safe cooperation

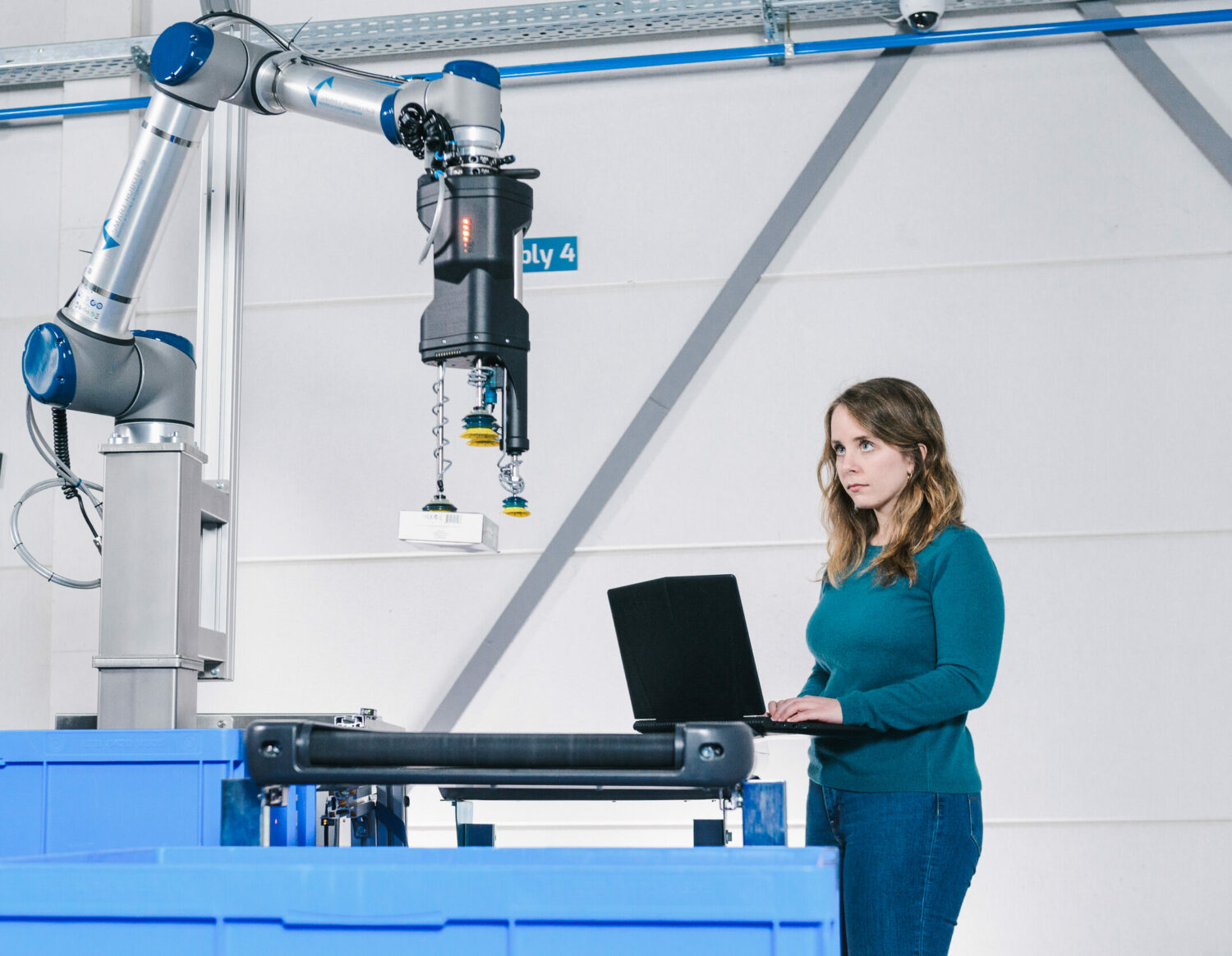

Item Picking with the Smart Item Picker

Meet the Smart Item Picker — a compact, reliable solution for efficient single-item picking and placing across a wide variety of products. It integrates effortlessly into your apparel fulfillment process and is user-friendly for any employee. Easily scalable and adaptable to your production setup, the Smart Item Picker helps you optimize your fulfillment operations with ease.

Book a demo

Case

studies

As a trusted automation partner to over 120 customers, we help businesses reduce costs and achieve ROI within a year. See how our automation solutions are making a difference — straight from our customers.

Did you know that Bol.com, one of the largest Dutch online retail & distribution companies, executed a pilot with Smart Robotics regarding the implementation of a Smart Item Picker?

Read more >Vandemoortele, a leading food production company, is significantly saving costs after having implemented a Smart Palletizer.

Read more >24/7

Operation

99.7%

Availability Rate

<1

Year ROI

Packservice, a large co-packing group, implemented a Smart Palletizer to help solve their labor shortage and improve employee health

Read more >

24/7

Operation

Improve ergonomic circumstances of human employees

99.7%

Availability Rate

Stacking closed and open boxes without problem

<1

Year ROI

Saving 1 operator per shift

Book an

Online Demo

Learn how to improve apparel fulfillment efficiency with a reliable item picking robot

Download our free white paper

Learn all about how to find the ideal pick & place robot for your warehouse. Leave your contact details for free access to the whitepaper. You will receive an email with a download link to the whitepaper.

Read our blogs

7 key trends shaping the warehouse of the future

05-02-2025

What’s next for warehousing? Discover 7 key trends—from AI-driven inventory to cobots—that are transforming the warehouse of the future.

Read moreThe future of bakeries: must-know trends for 2025

15-04-2025

In 2025, consumers continue to demand more and more from the bakery industry. It is time to consider how to improve the production process to meet these demands. Learn about the latest bakery trends and why bakery automation is key.

Read more5 reasons why end-of-line automation in the food industry is key

25-05-2022

Global labor shortages continue to rise, also in the food (processing) industry. Automation is key, but where to start? End-of-line automation with cobots or robots can be the perfect first step. This blog gives 5 reasons why end-of-line automation is key.

Read moreFAQ

Food Industry

A cobot palletizer or robot palletizer is an automated material handling system that stacks goods and products onto a pallet. It is usually placed at the end of a production line and allows for stability, precision and high efficiency.

Read more about cobot palletizers >A cobot palletizer or robot palletizer is an automated material handling system that stacks goods and products onto a pallet. It is usually placed at the end of a production line and allows for stability, precision and hQigh efficiency.

Read more about cobot palletizers >A cobot palletizer or robot palletizer is an automated material handling system that stacks goods and products onto a pallet. It is usually placed at the end of a production line and allows for stability, precision and high efficiency.

Read more about cobot palletizers >A cobot palletizer or robot palletizer is an automated material handling system that stacks goods and products onto a pallet. It is usually placed at the end of a production line and allows for stability, precision and high efficiency.

Read more about cobot palletizers >A cobot palletizer or robot palletizer is an automated material handling system that stacks goods and products onto a pallet. It is usually placed at the end of a production line and allows for stability, precision and high efficiency.

Read more about cobot palletizers >Have another question? Contact us