Table of Contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Why you should automate your box palletizing now

Table of Contents

Imagine running a facility manually, only to find out that automating your end of line can increase throughput per hour by around 200% – 400%. Not only that, but it reduces your reliance on finding new labor, manage increasing costs, and decreases product damage.

In fact, studies show that up to 10–11% of pallet loads arrive damaged, and around 12.5% of product damage is pallet-related, which highlights the risks manual palletizing creates.

In this article, we’ll showcase (with real-life examples!) how automating your box palletizing can significantly increase the efficiency and productivity of your facility.

The hidden costs of manual palletizing

Many warehouses choose to automate their end-of-line for reasons such as:

-

- Constantly needing to hire and train new staff, only to lose them soon after due to health issues or the repetitive nature of the work.

- Rising labor costs that don’t translate into higher output or improved consistency.

- Quality and throughput varying from shift to shift, creating inefficiencies and delays.

- Growing pressure to meet faster delivery schedules that manual palletizing simply can’t sustain.

These are hidden costs many businesses don’t have a spreadsheet for to monitor, but it can heavily hinder the profitability of the company.

How automated box palletizing works

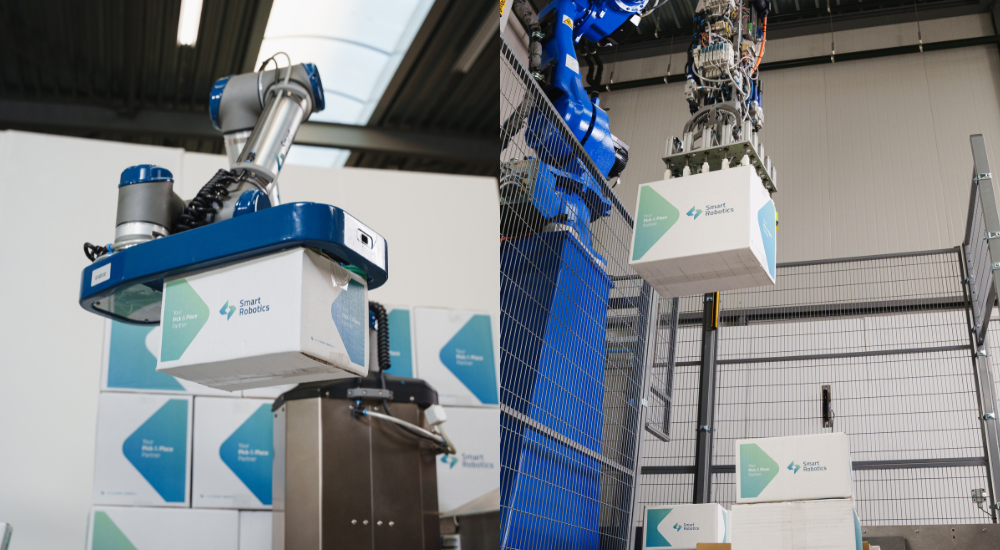

Simply put, automated box palletizing uses a robotic arm with a gripper, sensors, and intelligent software to lift each box from the conveyor and place it gently onto the pallet.

Reducing product damage

Every movement of the automated palletizer is carefully controlled, gripping each box securely and placing it gently onto the pallet. The result is a neat, stable stack where every box is exactly where it should be and weight is evenly distributed to prevent shifting in transport.

In short, the gentle handling and precision of automated palletizing mean every pallet arrives just as perfect as when it left your line.

Boosting efficiency & output

With companies like Heinerle Berggold finding that automating their palletizing could cover almost three employee shifts, it was almost a no-brainer for them to start automating.

With automated palletizing, you can achieve virtually no downtime; simply because the robot doesn’t get tired, need a bathroom break, or call in sick. On top of that, output increases significantly, as one robot can palletize up to 1,600 cases per hour (more than double what an operator can do). And if your products change or sizes need updating, the team can easily use the Online Product Editor to make adjustments in no time.

In fact, one of the core reasons the Smart Palletizer was chosen over other solutions, according to the German bakery Lebkuchnerei Woitinek, is the system’s user-friendliness. It’s almost as easy to operate as a smartphone.

ROI and competitive advantage

Investing in automated palletizing delivers a return you can measure. By reducing the returns based on product damage, you cut unnecessary costs and protect your margins.

Furthermore, faster, more consistent fulfillment keeps customers satisfied and service levels high, strengthening your reputation. And with a system that can easily scale as your business grows, you’re not just solving today’s challenges; you’re building a competitive advantage for the future.

Implementation considerations

Before you invest in automated box palletizing, it’s important to think through a few key factors. It doesn’t have to be complicated—and at Smart Robotics, we make sure it isn’t.

We’ll assess your floor space to ensure the solution fits seamlessly into your layout, and we’ll handle integration with your existing or new equipment and software so everything works together without disruption.

Our cobot palletizer is designed with safety at its core, using vision and motion sensors to prevent collisions with operators. We can also implement additional safety measures, such as light curtains, to create an even safer working environment.

And when it’s time to go live, we provide hands-on staff training so your team feels confident and ready to get the most out of the system from day one.

Bottom line

Automating your box palletizing is absolutely necessary to stay ahead in this competitive market. Labor is short, retraining costs are high, and manual processes create bottlenecks that slow down your entire operation. With automated palletizing, you gain reliability, higher output, and flexibility — all while reducing dependency on scarce labor. In short, automation is no longer a nice-to-have, but a must-have for long-term competitiveness.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Frequently Asked Questions

Automated box palletizing uses a robotic arm, sensors, and smart software to stack boxes neatly and consistently on pallets. It removes the strain of manual work and ensures every pallet leaves your facility stacked in perfect condition.

Labor is short, costs are rising, and customers expect faster deliveries. Automating now means you stay ahead instead of playing catch-up. The sooner you start, the sooner you benefit from higher output and lower costs.

A lot. Around 10–11% of pallet loads arrive damaged, and 12.5% of all product damage is pallet-related. With an automated palletizer, every movement is precise and controlled—so your pallets stay stable and your products arrive safely.

Ready to automate your box palletizing?