Table of Contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

How automated item picking solves seasonal demands

Table of Contents

The season has just begun. Back-to-school, Black Friday, Cyber Monday, and Christmas are all around the corner – and with them comes mounting pressure on warehouses. While customers expect fast and flawless deliveries, the reality behind the scenes is often very different: workforce shortages, rising costs, and increased error rates can quickly turn this season into a stressful challenge.

Don’t get us wrong, some warehouses and production centers are more prepared than others. But what remains true is this: having systems in place to handle surging order volumes, strict fulfillment SLAs, and ongoing labor shortages is the only way to get through the season with your customers behind you, rather than watching them abandon ship.

Picture this: a warehouse running perfectly on AS/RS cube solutions or robotic goods-to-person systems. That’s automation that has already transformed efficiency in many warehouses — so much so that some can’t even imagine going back. But with automated item picking, you take efficiency one huge step further.

Defining peak season

Peak season usually runs from the end of August through January, and sometimes even longer. But not every industry feels the pressure at the same time. Summerwear brands might hit their peak between April and July, while electronics brands often face it during the back-to-school rush.

The labor challenge

It’s not “news” that labor shortages are causing bottlenecks across Europe. While many European employers struggle to fill manufacturing roles, it’s becoming clearer that applicants simply don’t find these jobs attractive. They simply have opportunities to apply their skills elsewhere.

In fact, according to the 2023 EURES Labour Shortages and Surpluses in Europe report, even when the required skills exist, employers still fail to attract applicants due to poor working conditions or uncompetitive job offers.

And it’s not just in reports or studies. Most of our customers come to us because of labor shortages. Take Melitta, the famous German coffee brand or Packservice for example, their main reason for automating their end-of-line was simple: they couldn’t find people to do the job. And that’s not only during seasonal peaks. That’s all year round.

Automated picking technologies to the rescue

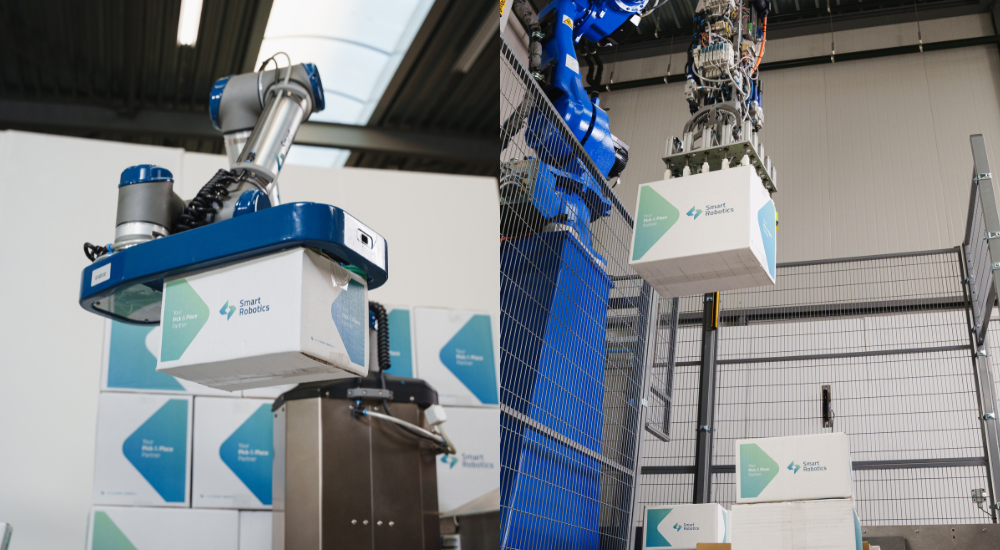

With technologies like AMRs, robotic goods-to-person, and AS/RS all around to enhance and optimize work, it might be worth looking into item pickers. Automated item pickers can be integrated with AS/RS, cube storage, or even AMRs to fulfill orders. They can pick an item and place it into a shipping box, transfer it into another tote, or put it directly onto a conveyor belt.

Our item pickers are fast, lifting up to 1,000 items per hour. They handle products gently and don’t require pre-training, thanks to our AI vision sensors. In other words, it can pick and place an item it has never seen before exactly where you need it. On top of that, our solution comes with integrated barcode scanning.

Plan smarter with automation

Peak season should never feel like a burden or cause anxiety for organizations. Yet too often, warehouses scramble in September, desperately patching up process gaps. The smart way? Plan months before your expected peak. By analyzing last year’s data and pinpointing where the bottlenecks were, you can fix weak spots before they slow you down again.

From seasonal fix to long-term strategy

The beauty of automated item picking is that it’s not just a seasonal Band-Aid. When peak volumes drop, your systems don’t sit idle, they keep delivering consistency and efficiency all year round. This is how you shift from firefighting during peak season to building a fulfillment backbone that scales with your business.

In other words, automation shouldn’t just show up in a crisis, it should be thought through and planned months before peak season.

Benefits of smart picking during peak season

Three things come to mind when you think about automating your item picking: consistent output, reduced reliance on labor, and scalable fulfillment that grows as you grow.

Consistent output

Manual picking is unpredictable. Performance depends on the time of day, how long a worker has been on shift, or whether they’re seasonal, temporary, or full-time. With automated item picking, you get the same speed and accuracy on order 1 as you do on order 10,000. That means fewer mispicks, fewer complaints, and fewer headaches when customers expect perfection during peak.

Reduced reliance on labor

Hiring temporary workers for peak season sounds good on paper, until you realize how much time and money it takes to recruit, onboard, and train them. And even then, turnover is almost unavoidable. Automation cuts that cycle out completely. Instead of chasing staff, you let the system do the heavy lifting, literally and figuratively.

Scalable fulfillment

This is where automated picking shines. Whether orders double or triple, automated item pickers don’t get tired. They simply keep going. And once the season slows down, they keep adding value by running your daily operations with the same efficiency. In other words: you’re not investing in a seasonal fix – you’re building a scalable backbone for growth.

The future of seasonal fulfilment

Seasonal peaks will always be there. What changes is how prepared you are to handle them. Warehouses that rely purely on manual labor will keep facing the same challenges: delays, errors, unhappy customers. But those that embrace automation, AI, and data-driven strategies can turn seasonal chaos into a smooth, scalable operation.

At the end of the day, the question isn’t whether peaks will test your operations. It’s whether your systems are ready to rise to the challenge.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Frequently Asked Questions

Unlike seasonal staff, robots don’t need training or breaks. Automation ensures consistent output even when order volumes double or triple, making it ideal for seasonal peaks like back-to-school, Black Friday, and Christmas.

No, automated picking boosts efficiency all year round, reducing dependency on labor and delivering consistent performance beyond peak seasons.

Technologies like automated item picking, AS/RS, AMRs, and goods-to-person systems help warehouses scale quickly, reduce errors, and manage labor shortages during peak demand.

Ready to boost order fulfilment during seasonal peaks?