Nupac improves employee safety at Australian Milk Formula manufacturer

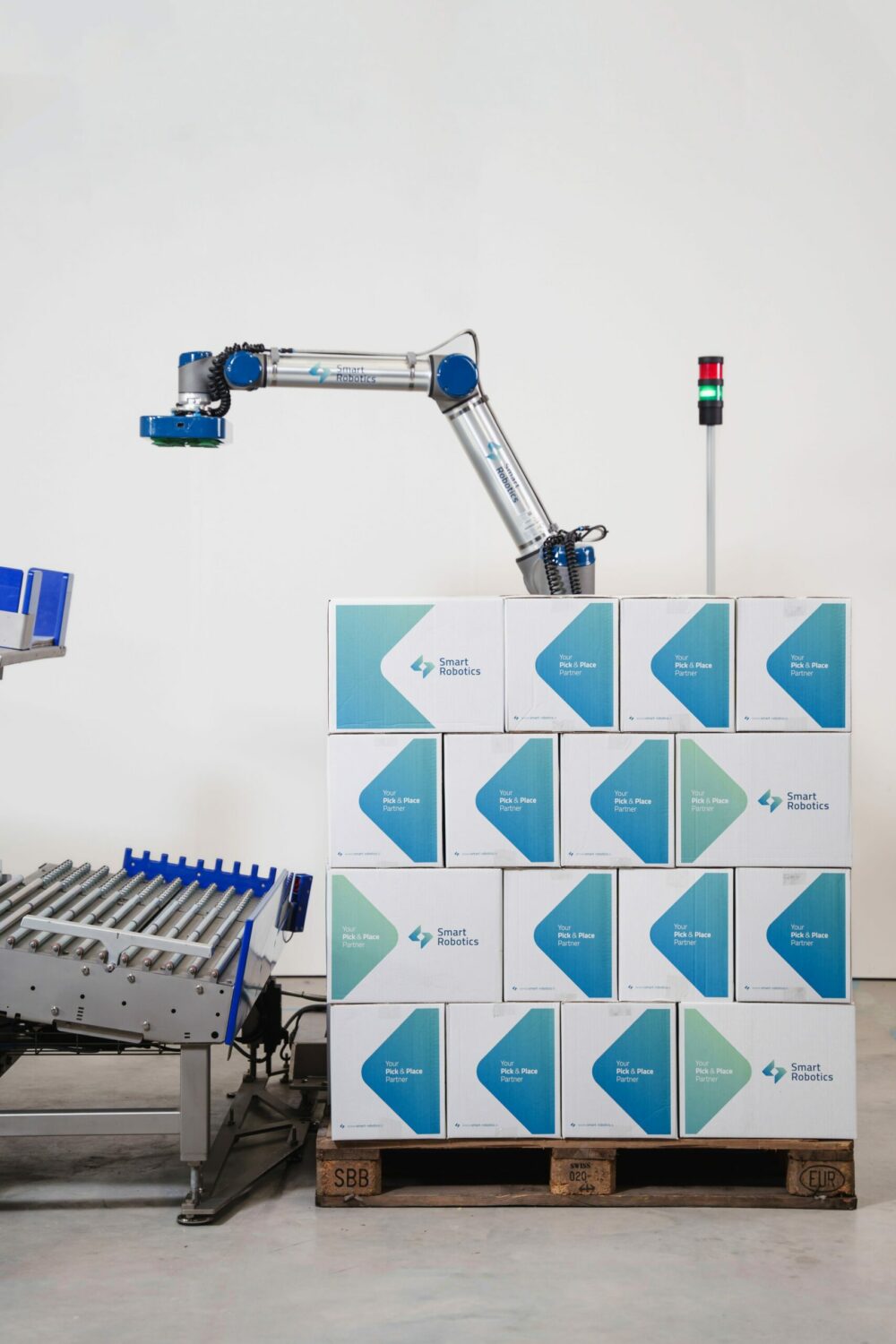

An Australian Milk Formula manufacturer was looking for a palletizing solution to reduce labor costs and improve employee safety. They reached out to Nupac, a partner of Smart Robotics active in Australia and New Zealand. The Smart Palletizer that was implemented was rewarded with the nomination for Safety Award. It reduced labor cost with 50% and had a return on investment (ROI) of less than eleven months.

Increase safety & efficiency

Using a manual stacking process, the milk formula manufacturer had two staff members packing cases from the case packer onto pallets. This process created a range of health and safety issues, including RSI and back complaints due to the repetitive nature of the task. In addition, the stacking process and height of the pallets created blind spots for forklifts, increasing the likelihood of accidents. As a result, the customer was looking to increase the safety of their packaging process, while at the same time reduce costs and increase efficiency. A palletizer cobot was the perfect solution.

Safety award nomination for palletizer

After working closely with the customer to analyze the project requirements, Nupac provided the Smart Palletizer, an intelligent cobot solution. As an accurate, safe and efficient solution, the Smart Palletizer has a small footprint and was an easy fit into the current customer’s processing and packaging line. Providing automated palletizing, the Smart Palletizer also provided 24/7 palletizing capabilities. Through using this solution, the customer was able to reduce their labor requirements from two individuals to less than one, while also eliminating the previous health and safety risks involved in the palletizing process down to zero. As a result of minimizing staff injuries and hazards, this project was nominated for a safety award.

Palletizer ROI within 11 months

With the line currently operating 24 hours, 5 days a week, the customer is extremely satisfied with the solution, stating that they have seen a return on investment on their palletizer within 11 months, with reduced downtime and eliminated safety hazards, creating a better environment for the business and staff.

Palletizer ROI of less than 1 year