Table of contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

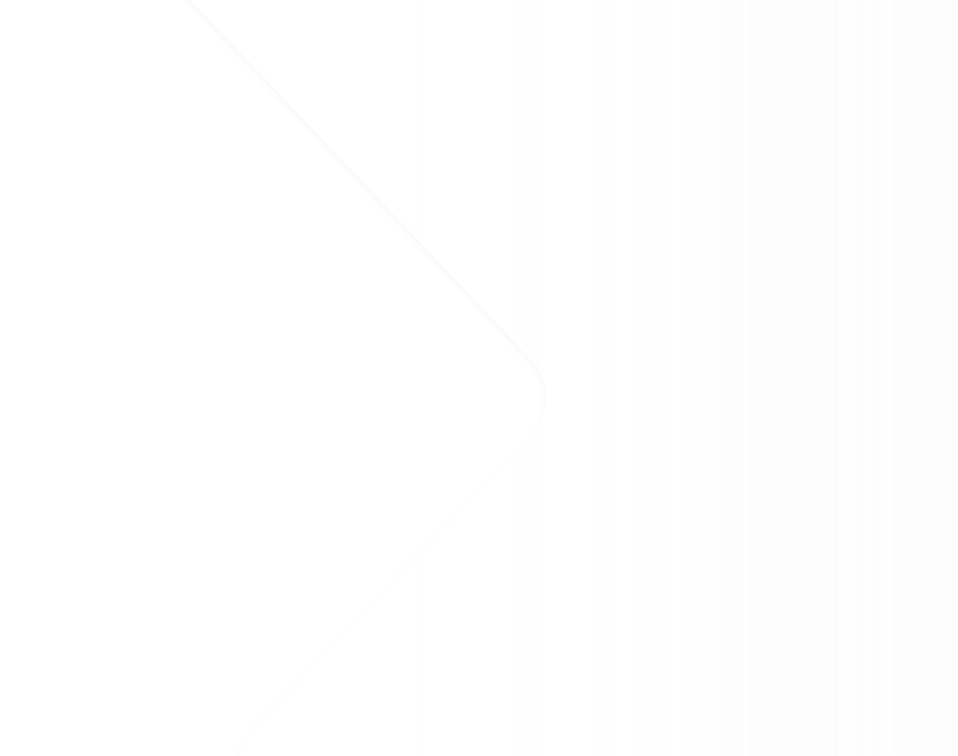

Implementing pick & place robots in your warehouse – step 2: proof of concept

Table of contents

For many companies, implementing pick and place robots in their warehouse is very new. Good preparation is needed. To come to the best decision, there are four phases to go through: exploration, proof of concept, design and implementation. In this blog series we will discuss what steps to take in each phase to ensure the successful implementation of pick and place robots in your warehouse. Now that you have passed the exploration stage discussed in the first blog, this second blog will help you build your requirements and a proof of concept for a successful pick & place robot implementation.

Step 1: What questions do I still have following the exploration phase?

What parts of your exploration phase are still unclear? What would you like to clear up? Especially think about:

- Pickability: can the robot handle my product assortment? Do we need to request changes from our supply chain? Do we need to blacklist certain products? What exceptions exist that we did not think about before?

- Speed: can the robot meet my KPI’s and desired throughput?

- Operator interventions: how often do these occur? What training would my operators need? Will they be able to work easily with the robot?

Step 2: What test environment is suitable to fulfill my needs?

Once you know what questions you still need answers to, think of what type of test environment can help you get the answers you need. It may be sufficient to execute a simple test with a few of your products at the supplier itself. However, if your questions and concerns go further than that, testing the robot in your operation is preferred.

For example, if your warehouse handles millions of different items each day, a simple test at the supplier will not be adequate. Rather, test the pick and place robot in your actual operation to discover what it is able to handle and whether it is a suitable solution for you. But what if you are building a new warehouse? It is still advised to test the robot in an existing warehouse, even if it is not fully optimized for robots. It can help give you an idea of the robot’s capabilities and pitfalls

Step 3: How do we implement the test robot in an easy and accessible way?

If you have decided to test the robot in your warehouse, you should think of what is needed to get to a minimal implementation. Above all, you want to test the robot without having to make too many changes in your fulfillment process.

First, you should try to limit the interfacing with surrounding systems. The more interfacing needed, the more time and effort it takes to test the robot. Hence, think of topics such as: does the robot need to link with my WMS? Or can a human operator make a manual translation to the WMS for a few days? On top of that, consider when to test the robot in your warehouse e.g. seasonal variety may bring important variances in your process that should be added to the tests.

Step 4: set goals and KPI’s for the pick & place robot

To get the most out of your proof of concept phase, it is critical to set pick & place goals and KPI’s in cooperation with your supplier, as well as how to measure them. What minimal requirements does the pick and place robot need to meet? Think of speed, pickability and operator interventions. Think this through thoroughly, so you can make sure you learn all you need to learn in the proof of concept phase.

Step 5: execute and evaluate the pick & place test

Once you have explored what test environment is suitable, the minimal implementation needed and have set goals and KPI’s, it is time to start the actual testing of your pick and place robot. During the test, it is important to:

- Continuously monitor and analyze the results and adjust the test setup accordingly in close cooperation with your supplier.

- Communicate intensively with relevant stakeholders so they are up to date on the progress of the test.

After the proof of concept phase, you will design the pick & place robot implementation plan in detail. This design phase will be discussed in the upcoming blog as part of the ‘implementing robots in your warehouse’ series. Stay tuned!

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Download our free white paper

Learn how to implement the ideal pick & place robot in your warehouse. Leave your contact details and receive a download link to our free white paper.