Discover Our

Warehouse Automation Solutions

From automated item picking to palletizing and depalletizing solutions, we’ve transformed warehouses and production sites across Europe. Click on the map to explore.

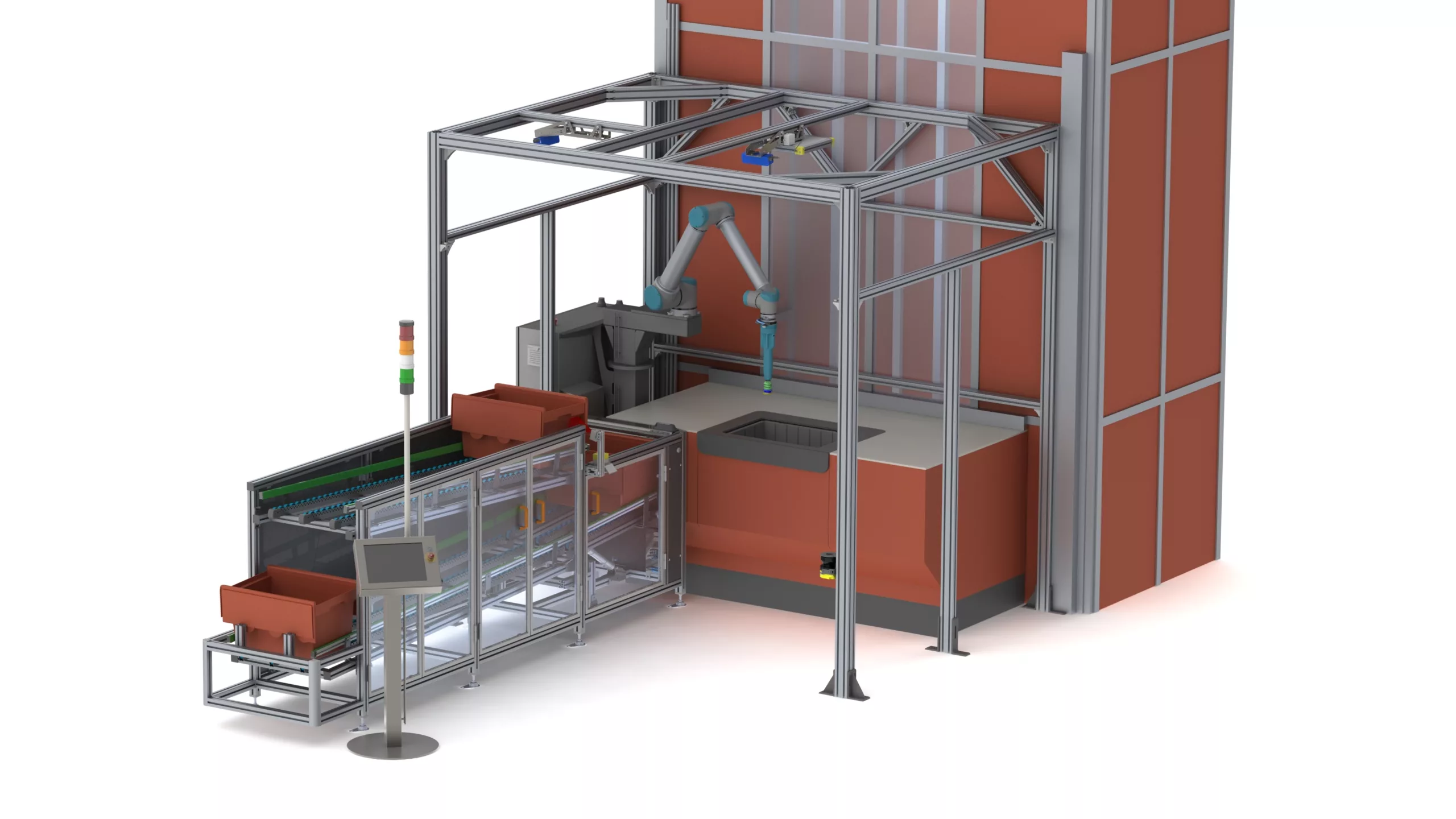

What are warehouse robots?

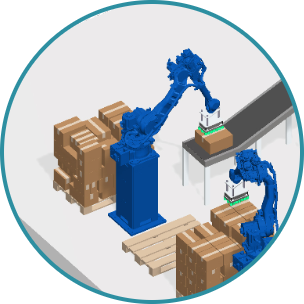

Warehouse robots are designed to improve the flow of goods, accuracy, and safety in warehouses across the logistics industry. Warehouse robots can be implemented in different processes to perform various operations to boost productivity. There are an increasing number of robots being used in logistics operations for inbound, storage, stock management, order picking and outbound processes. Here are the main types of robots you can find in a warehouse:

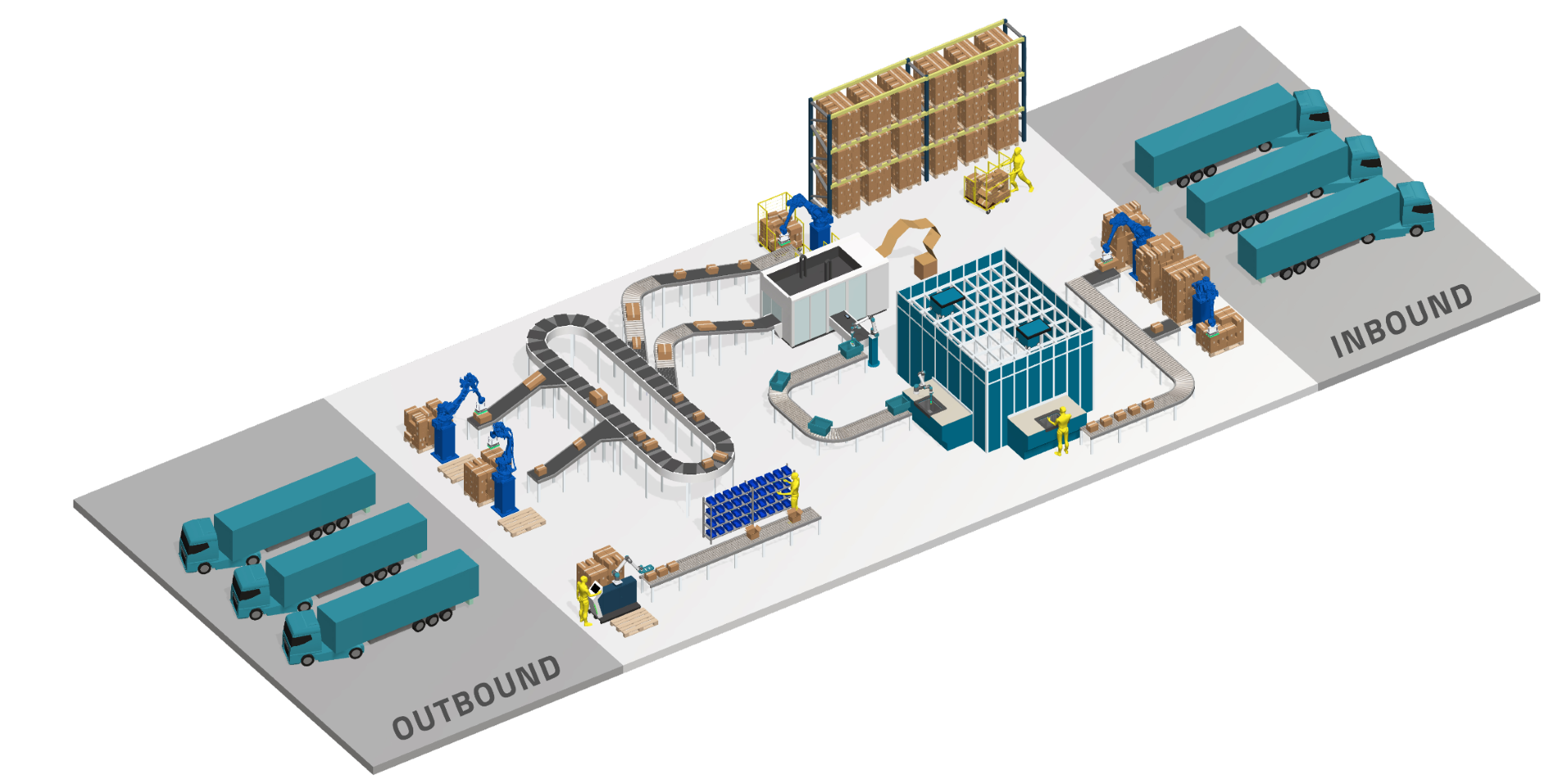

What is an

automated warehouse?

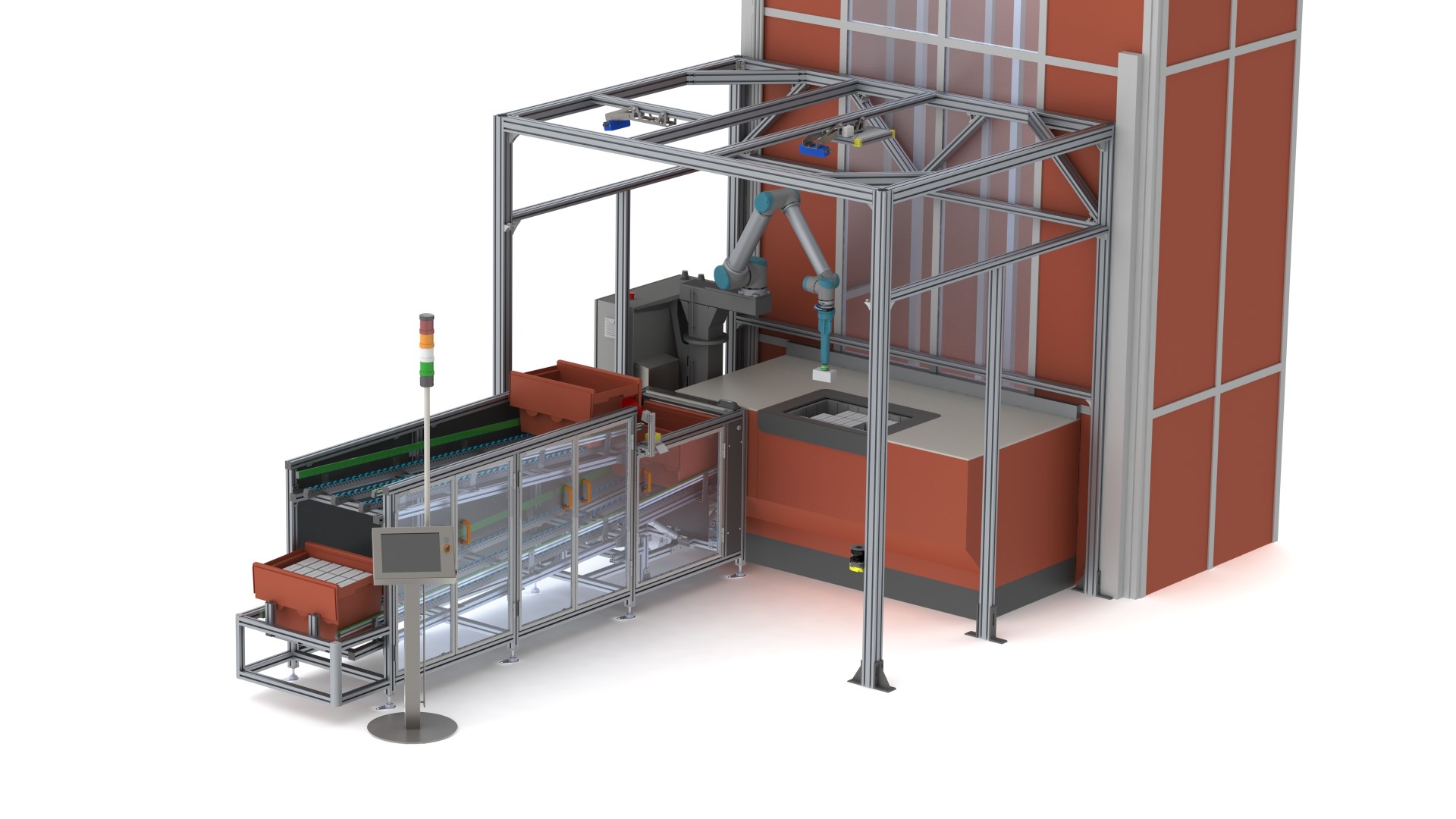

An automated warehouse is where all warehouse operations, such as inbound, storage, sorting, packing, and outbound, are automated by implementing a system.

With an automated warehouse, a small team can perform warehouse operations efficiently.

The logistics industry has experienced a surge in activity, driven by the rise of online shopping. However, this growth has also led to a shortage of employees and drivers, affecting organizations across a wide range of industries, such as E-commerce, Food, Fashion, Pharma, 3PL and Healthcare.

Your actionable guide to a successful warehouse automation strategy

With over 10 years of automation expertise, we’ll help you boost ROI, avoid costly pitfalls, and build a strong business case for warehouse automation. Fill out the form to access the whitepaper’s exclusive insights—and enjoy the read!

More information about warehouse automation

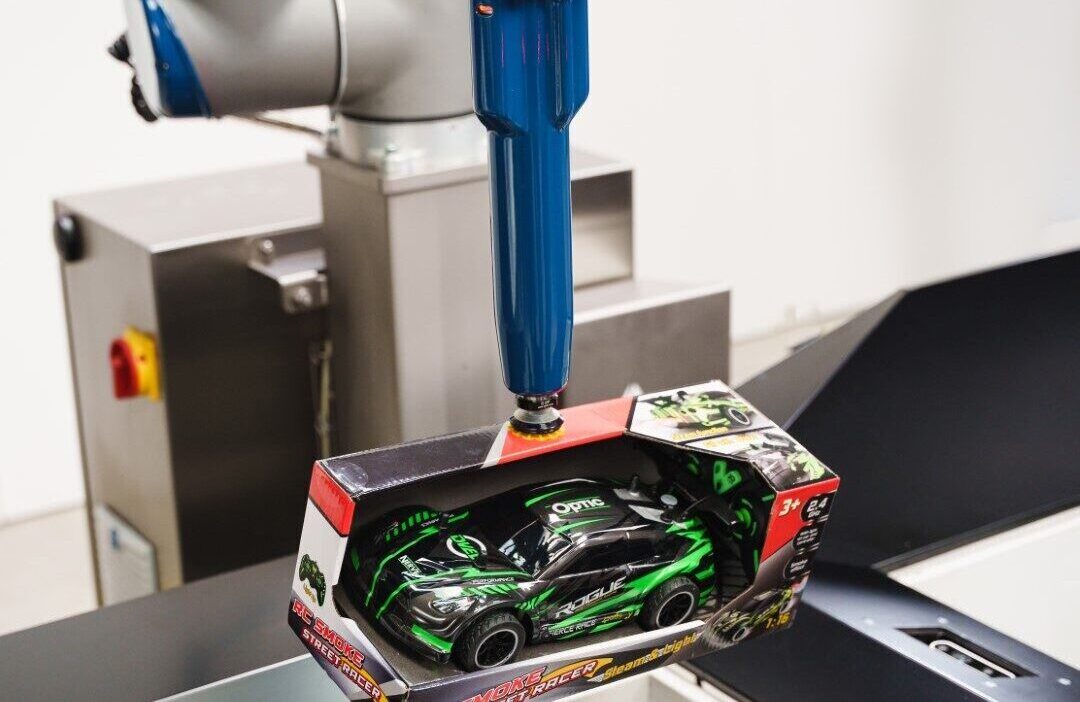

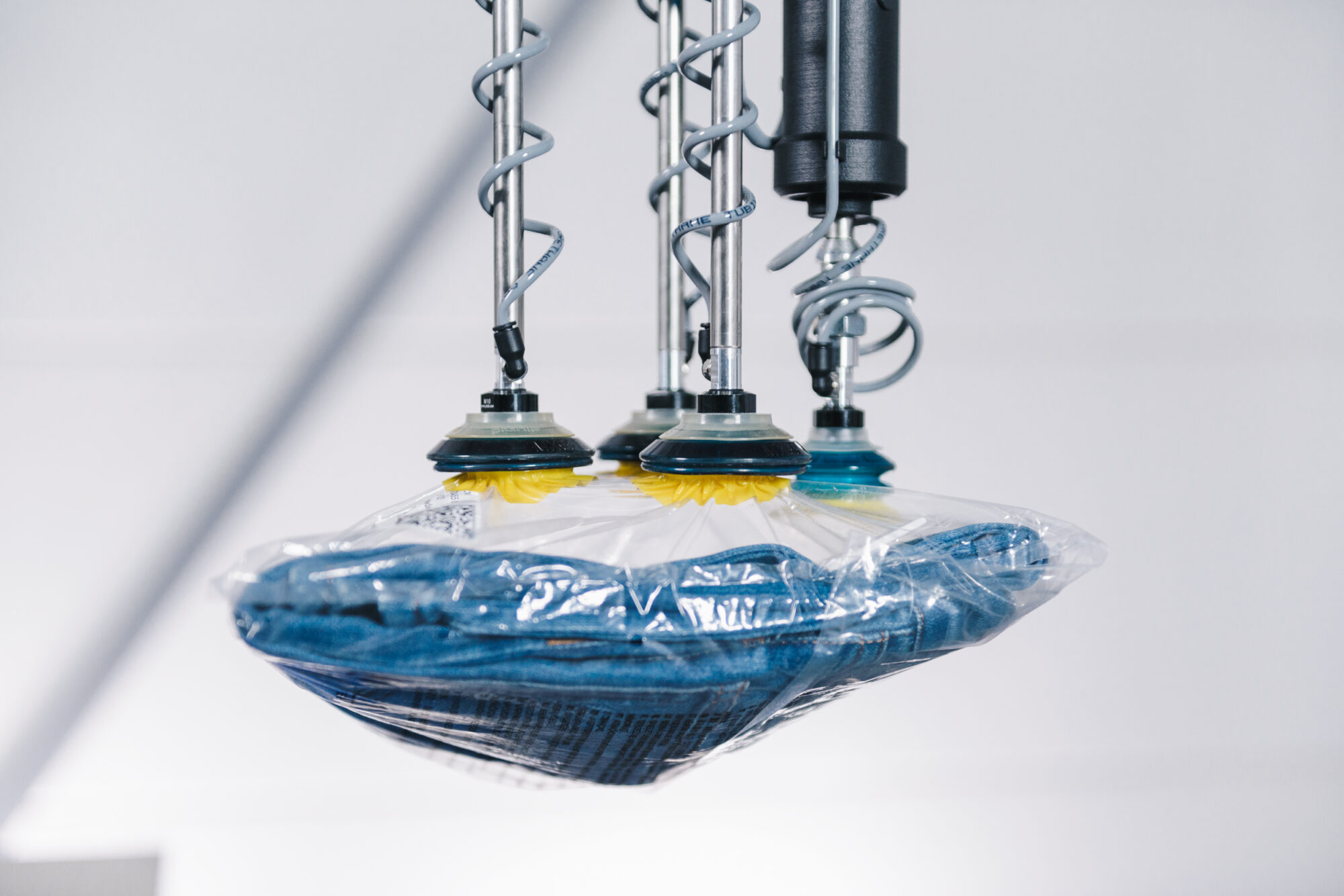

What is a pick and place robot? Types & benefits explained

Discover what pick and place robots are, how they work, their benefits. Learn about types, advantages, and how they improve efficiency, accuracy, and ROI.

Read more

2023 apparel fulfillment trends that emphasize the need for automation

In 2023 there is an increasing need to have a more efficient and sustainable fashion fulfillment process. This blog discusses the fulfillment and logistics trends for the apparel industry in 2023 that emphasize the need for automation.

Read more

Autostore: Transforming Warehousing with Goods-to-Robot Efficiency

Most warehouses already have an goods-to-person system in place. But what if you turn that into a goods-to-robot system? Combining a system such as AutoStore with pick & place robots can help you reach optimal fulfillment throughput and optimize warehouse capacity.

Read more

The top 5 e-commerce fulfillment trends in 2025

Discover 2025’s top 5 ecommerce trends: rising automation, micro-fulfillment centers, same-day delivery, and key insights to help you thrive in a $6.5 billion industry.

Read more

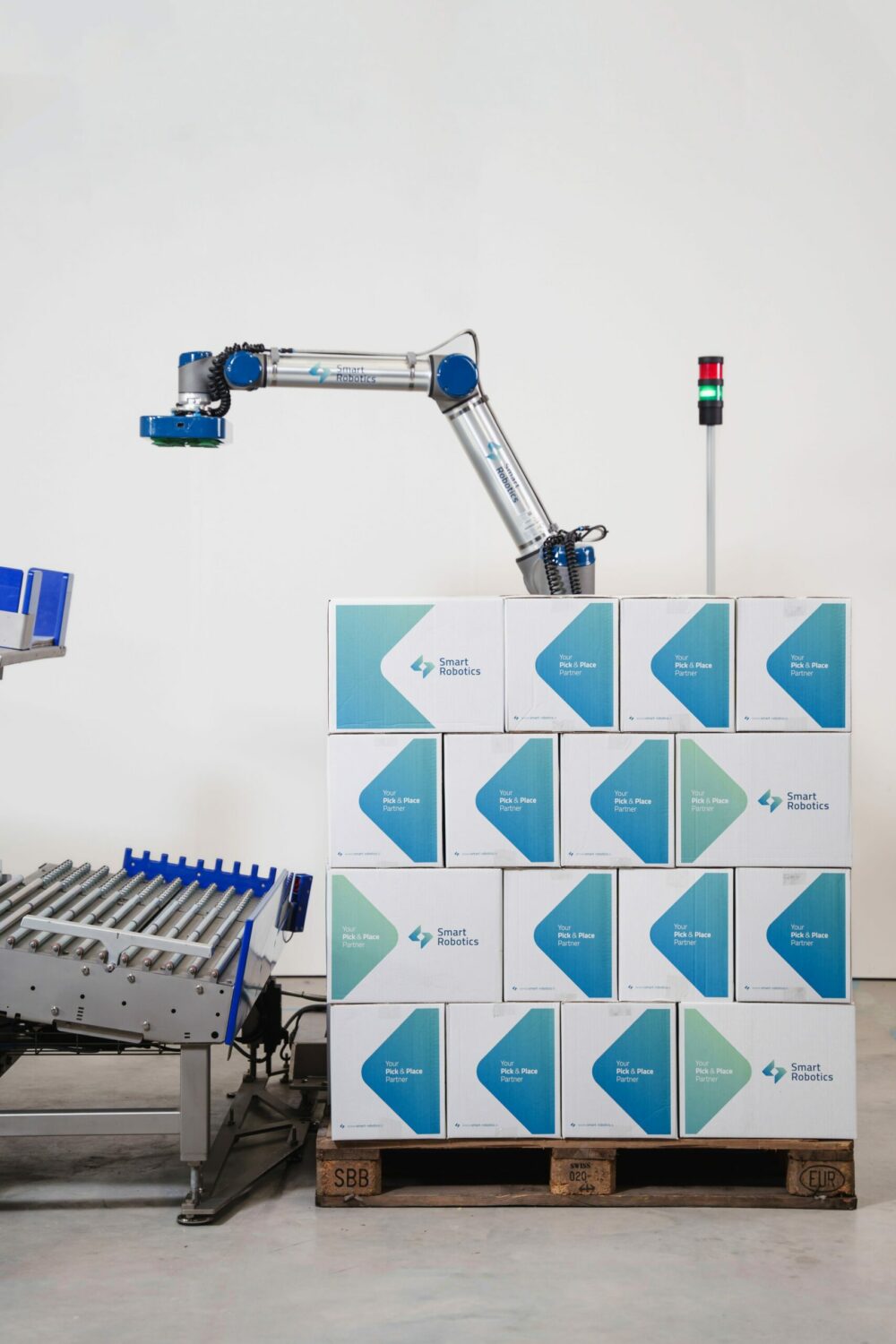

3 signs you are ready for a cobot palletizing colleague

Palletizing can be a repetitive and monotonous task. When are you ready to automate it with a cobot palletizer?

Read more

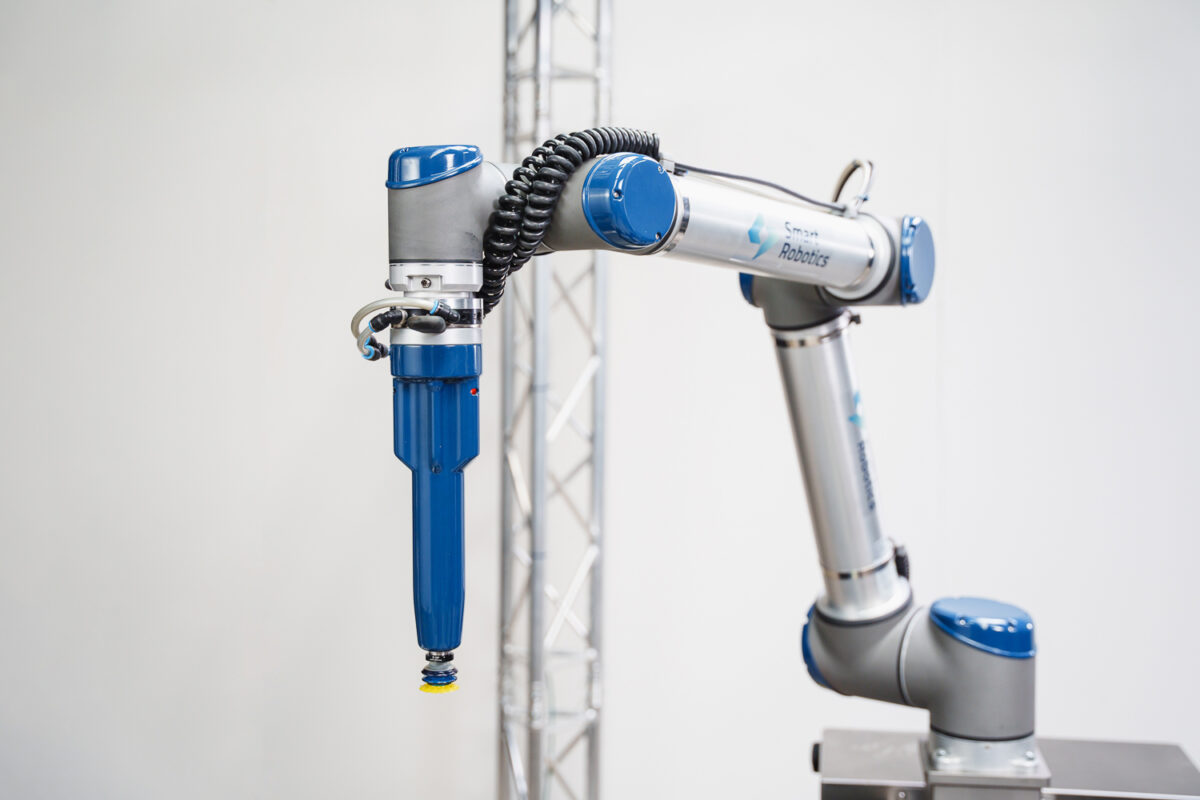

A robot or cobot in your warehouse? Advantages & disadvantages

There are advantages and disadvantages to both robots and cobots. Learn more about both options to discover which one meets your needs.

Read more