Table of contents

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

What is a cobot palletizer? Benefits, industries & applications

Table of contents

For decades, logistics workers had to manually lift and stack cases onto pallets—a physically demanding and time-consuming task. Then came industrial palletizers in the 1970s, taking over the heavy lifting—literally—from workers. Over time, these machines have continued to evolve, leading to the introduction of what we now know as a cobot palletizer.

What are cobot palletizers?

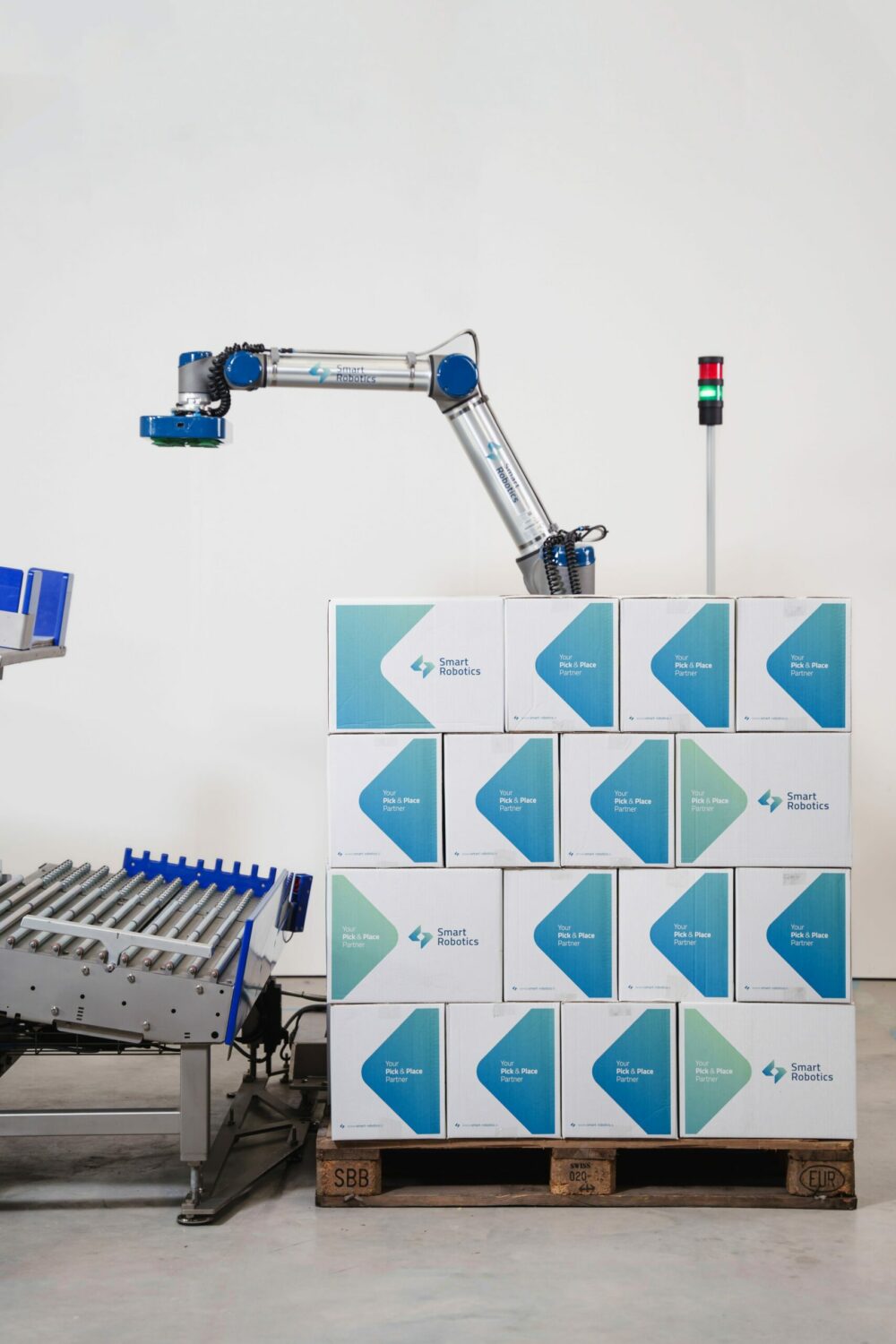

To put it simply, cobot palletizers are a more compact, easy-to-install, and user-friendly alternative to industrial robots. They are essentially designed to automate the stacking of goods onto pallets—and, in some cases, into cages and onto trolleys.

Unlike traditional industrial palletizers, these machines work safely alongside employees, eliminating the need for fencing. They serve as a stepping stone for logistics facilities looking to automate and speed up their end-of-line processes.

What are the advantages and benefits?

Increased throughput

Unlike manual palletizing, cobots can handle up to 1,000 parcels per hour. They perform these tasks tirelessly, ensuring consistent productivity without the need for breaks or sick leave.

Enhanced employee job satisfaction

By taking over monotonous and physically demanding tasks, cobots allow employees to focus on more engaging and value-driven activities, improving overall job satisfaction.

Tackles labor shortages

For years, manufacturers and logistics facilities have struggled to find workers for simple, repetitive jobs—and even more so, to keep them. Now, with cobot palletizers on the market, these machines can integrate into existing operations and help ease the pressure of finding and keeping employees.

Ease of operation and programming

Cobots are designed to be user-friendly, simple to install, and easy to learn. Some installations take less than a day to complete, meaning businesses can be up and running with minimal to no downtime. Internal personnel are also trained to troubleshoot issues as they arise, and Service Level Agreements (SLAs) with cobot solution providers offer additional support when needed.

Curious on how you can easily install a cobot palletizer in your organization? Contact one of our cobot palletizer experts today.

Reduced safety concerns

With built-in safety features and smart sensors, cobots can operate alongside people without requiring any safety barriers, reducing the risk of workplace injuries. Their compact design takes up far less space than traditional industrial robots, allowing workers to move around them freely and efficiently.

Which industries can benefit from cobot palletizers?

Cobot palletizers are especially useful in industries where space is limited, throughput is high, and labor shortages are an issue. Industries like manufacturing, food and beverage, and retail and e-commerce are just a few examples of those that can improve their operations with a cobot palletizer.

Food & beverage industry

Cobot palletizers can come in handy in an industry like food & beverage, as they can operate continuously and help alleviate labor shortages commonly found within this sector. Cobots are also easily adaptable, meaning they can handle a variety of packaging types, such as bags of flour, open-case boxes, and more.

Vandemoortele, a leading food producer and manufacturer in Europe, is a great example. They implemented a cobot palletizer to speed up their process and save costs—and have been successfully using this solution for years.

Pharmaceutical industry

As medicine products can be highly fragile, cobot palletizers can handle stacking cases on a pallet with great precision. They also minimize human contact with packaged medicines, meeting strict regulatory standards such as the FDA, GMP, and ISO.

Bayer, a renowned pharmaceutical company from Germany, implemented a cobot palletizer after Smart Robotics provided the necessary certifications for its use in their facility.

The cobot has been operating there for years, flawlessly integrating into their day-to-day operations—so much so that it’s now considered more of a ‘colleague’ than just a machine.

Packaging industry

In this industry, it’s crucial that different packaging types, such as cartons or trays, are handled without frequent reconfiguration. A cobot palletizer delivers on that, adjusting as needed. It also scales with production demands, adapting to seasonal spikes without relying on an already shrinking labor force.

After a seven-year search, Packservice, a packaging company in Poland, finally found the perfect solution to tackle labor shortages and speed up their end-of-line process: a cobot palletizer.

Cobot palletizers in a nutshell

Cobot palletizers are the answer to many challenges that come with running logistics facilities. From tackling labor shortages seen across industries such as food and packaging to speeding up end-of-line processes, they’re a great step toward future-proofing logistics operations.

Get in touch with our team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.