Find your ideal palletizer

We offer different types of palletizers based on your needs. Whether you’re looking at packaging type or the number of units per hour, we have a solution for you. Fill out the form to find out which palletizer best suits your operation.

Want to know more about your result? Below, you’ll find an explanation of what Essential, Advanced, and Premium mean. Prefer to speak with someone directly? Get in touch, and we’ll connect you with one of our experts.

Get your match in 30 seconds

Select your type of packaging

Boxes

Open boxes

Crates

Wraps

Select the number of units per hour

Choose Industry

Based on your requirements, we recommend the following solution:

Key Features:

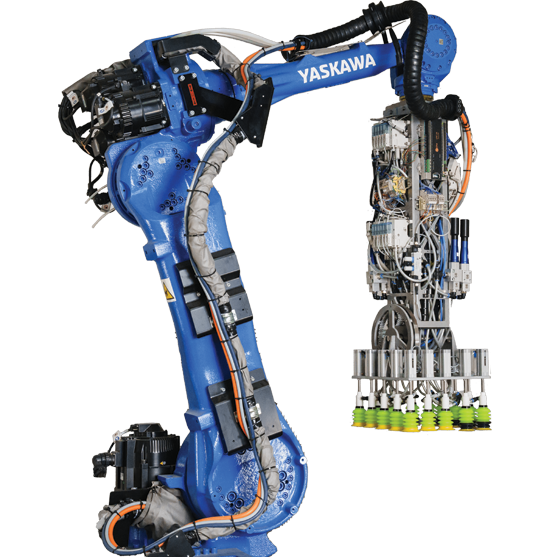

Types of cobot palletizer configurations

Compare the features of our Essential, Advanced, and Premium configurations for cobot palletizing. This guide will help you identify the right fit based on your unique operational complexity and flexibility needs.

Footprint (L x W)

Max stacking height

Max number of products or stacking patterns

Places sheets between layers

OEE Dashboard (real-time monitoring

Installed in half a day

Multi-picks (2+ cases at once)

Picks open-top boxes

Best for

Advanced

Extended flexibility

2.4 x 2.75 m

3m

20

Higher throughput operations with a wider range of products

Request infoPremium

Full palletizing capabilities

2.4 x 3.5 m

3m

unlimited

High-volume, multi-SKU operations needing open-box handling—now or in the future

Request infoFootprint (L x W)

2.4 x 2.3 m

Max stacking height

3m

Max number of products or stacking patterns

10

Multi-picks (2+ cases at once)

Picks open-top boxes

Best for

Simple operations with only a few products

Footprint (L x W)

2.4 x 2.75 m

Max stacking height

3m

Max number of products or stacking patterns

20

Picks open-top boxes

Best for

Higher throughput operations with a wider range of products

Footprint (L x W)

2.4 x 3.5 m

Max stacking height

3m

Max number of products or stacking patterns

unlimited

Best for

High-volume, multi-SKU operations needing open-box handling—now or in the future

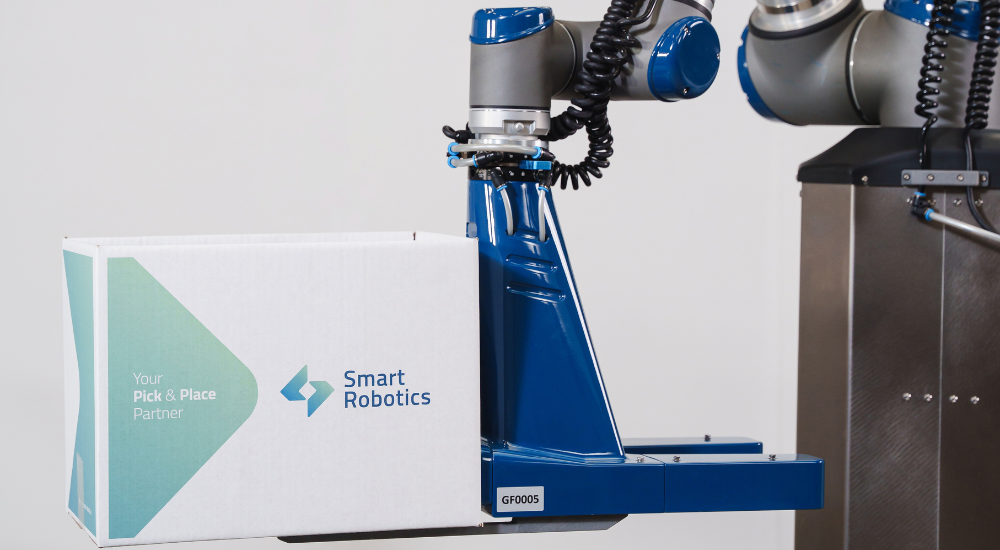

Smart Palletizer customers

Discover how our customers have improved their production and fulfillment processes with a reliable and efficient palletizing solution.

Vandemoortele, a leading food production company, is significantly saving costs after having implemented a Smart Palletizer.

Read more >24/7

Operation

99.7%

Availability Rate

<1

Year ROI

World-renowned Bayer, a pharmaceuticals and life sciences company, has welcomed the Smart Palletizer as a new colleague. Read more about why they recommend Smart Robotics to their partners.

Read more >Safe

palletizing system

Short

delivery times

Packservice, a large co-packing group, implemented a Smart Palletizer to help solve their labor shortage and improve employee health

Read more >Heinerle-Berggold Shokoladen GmbH, a German company specializing in specialty quality chocolates, has implemented a Smart Palletizer to help tackle labor shortages and to ensure on-time delivery to their customers.

Read more >3

Shift Operation

99.7%

Availability

“The Smart Palletizer has helped us solve our end-of-line challenges. It runs a 3-shift operation and reaches an availability of almost 100%.”

To further automate and modernize their coffee production, M.O.C.A. decided to take on the Smart Palletizer in their production process.

Read more >Easy

to use

Smooth

installation

“We immediately got the impression that Smart Robotics is a solid and reliable company.”

24/7

Operation

Improve ergonomic circumstances of human employees

99.7%

Availability Rate

Stacking closed and open boxes without problem

<1

Year ROI

Saving 1 operator per shift

Safe

palletizing system

One of the most popular colleagues

Short

delivery times

No need to interrupt production

“The Smart Palletizer has helped us solve our end-of-line challenges. It runs a 3-shift operation and reaches an availability of almost 100%.”

3

Shift Operation

24/7 reliability and efficiency

99.7%

Availability

Reliable palletizing of chocolates

“We immediately got the impression that Smart Robotics is a solid and reliable company.”

Easy

to use

By any operator without problems

Smooth

installation

Quick, well organized and good communication

Optimize end-of-line performance

Watch video

Thinking about automating your palletizing process?

We can help you understand what is possible and how our solutions can best fit your needs.

Fill out the form and check your inbox for:

- Our comprehensive product brochure

- A helpful whitepaper on implementing robotics in your facility

- A demo video of our palletizer in action

Ron Paulussen | Automation specialist

More information about palletizing

What are cobot palletizers? What are their benefits?

A cobot palletizer or robotic palletizer is a cobot system that stacks goods and products onto a pallet. What are the benefits of a cobot palletizer? And where can they be used?

Read more

5 reasons why end-of-line automation in the food industry is key

Global labor shortages continue to rise, also in the food (processing) industry. Automation is key, but where to start? End-of-line automation with cobots or robots can be the perfect first step. This blog gives 5 reasons why end-of-line automation is key.

Read more

The future of bakeries: must-know trends for 2025

In 2025, consumers continue to demand more and more from the bakery industry. It is time to consider how to improve the production process to meet these demands. Learn about the latest bakery trends and why bakery automation is key.

Read more